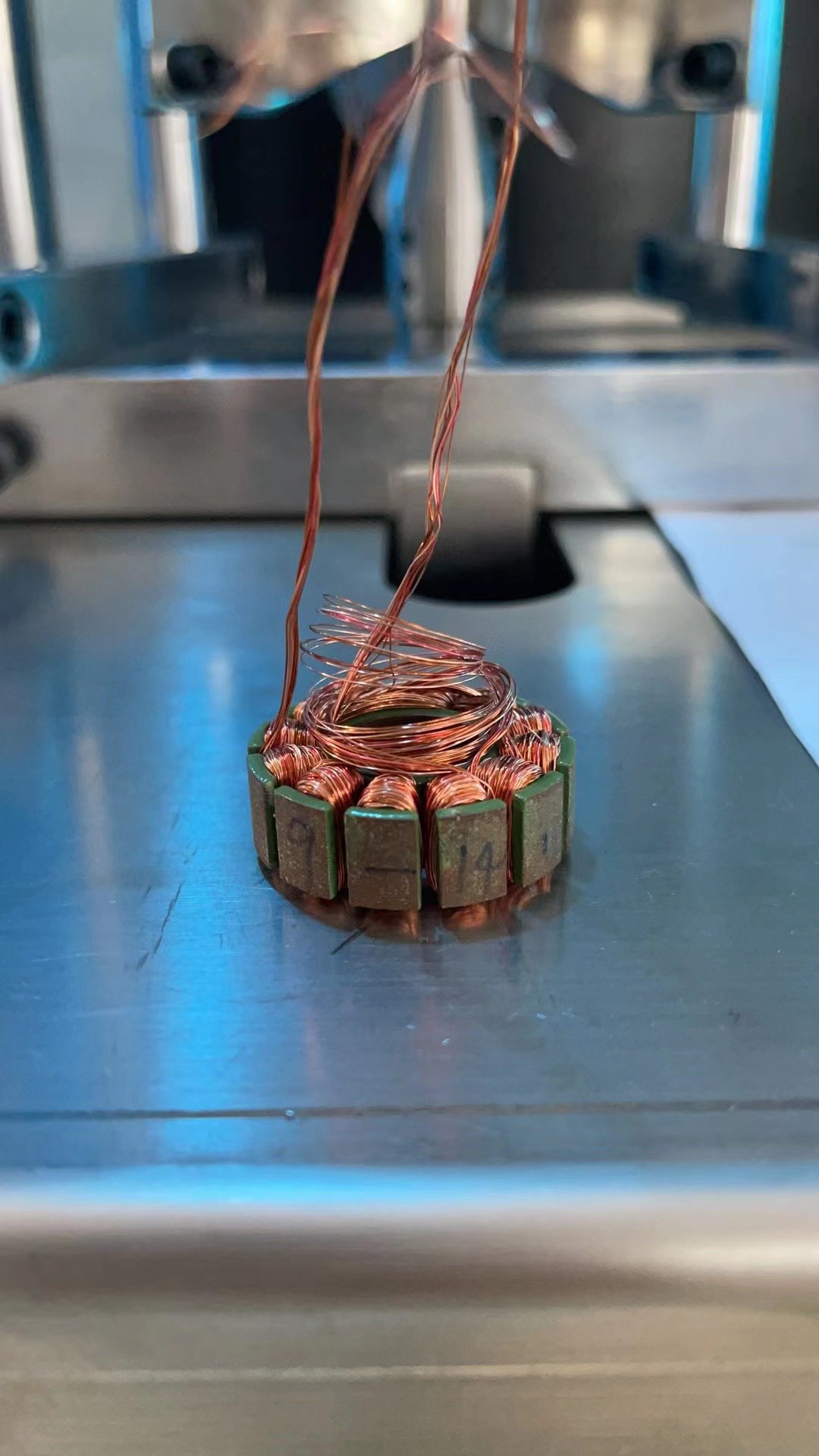

The stator structures of motors in model aircraft, drones, and racing drones are all similar: coils are wound around the stator, and when energized, they combine with the rotor to generate a magnetic field for rotation. Speaking of winding, specialized winding machines are needed. So, how accurate are brushless model aircraft stator winding machines? What are their technological advantages? Let Vacuz give a brief explanation below!

I. Precision Assurance Measures: Multi-Dimensional Control for Accurate Winding

1. High-Precision Servo Control System

Using internationally renowned brands (such as Panasonic, Fuji, and Delta) servo motors and controllers, and through multi-axis collaborative motion control algorithms, the system achieves micron-level control of the needle’s movement trajectory. This system can monitor and adjust the winding speed, tension, and position in real time, avoiding coil deformation or short circuits caused by speed fluctuations or positioning deviations. For example, when winding the stator of a micro-motor, the servo system ensures that each turn of wire is evenly and tightly arranged, significantly improving slot fill factor.

2. Precision Mechanical Structure and Materials

Chassis and Frame: A thickened square tubing welded chassis is used, with the lower part made of sheet metal and the upper part of an aluminum alloy frame. The worktable is made of stainless steel, ensuring vibration-free operation and high stability and rigidity.

Key Components: Auxiliary accessories such as lead screws, guide rails, cylinders, needle rods, and wire nozzles are all precision-machined to meet high wear resistance and high hardness requirements, reducing the impact of wear on accuracy during long-term use.

3. Intelligent Tension Control

The tensioner dynamically adjusts the winding tension according to the wire diameter and wire type (e.g., enameled copper, enameled aluminum), avoiding insufficient tension leading to wire slack or excessive tension leading to wire breakage. During debugging, a tension reference table is consulted, combined with a real-time feedback system, to ensure that each turn of wire is tightly packed and undamaged.

4. High-Precision Mold and Core Machining

The mold is machined using a turning, milling, and grinding machine, with a precision error controlled within 0.03mm. Special processes (such as quenching and surface plating) are used to improve wear resistance and hardness. Core production requires ensuring smooth surfaces and corners to prevent wire damage and breakage during winding. Precise fitting between the mold and the core is a direct guarantee of winding accuracy.

5. Multi-station Design and Automated Wire Laying

Supports single to six-station configurations. Four-station models offer a 300% increase in winding speed, suitable for mass production. Automatic indexing, automatic wire laying, and automatic clamping/cutting functions reduce manual intervention, improving production efficiency while ensuring neat wire laying. For example, a six-station model can wind six stators simultaneously, with each stator’s winding parameters independently controlled to ensure consistency.

II. Technical Advantages: High-Efficiency, Stable, and Flexible Production Solutions

1. Full-Process Automation and High-Efficiency Production

Achieves full automation of feeding, winding, and unloading, reducing human error. Combined with a multi-station design, a single machine’s daily capacity can reach 3-5 times that of traditional equipment, suitable for large-scale production needs.

2. Modular and Compatible Design

Modular Fixtures: Fixtures and jigs are designed as individual modules, allowing for quick and easy changeovers and reducing mold costs and downtime. For example, by adding shims or auxiliary parts, stator molds within the same series can be interchanged, covering the winding needs of DC brushless motors, stepper motors, and other applications.

Wide Wire Diameter Range: Capable of winding 0.08-1.3mm enameled wire, meeting the needs of micro- to medium-sized motor products.

Cross-Series Adaptability: Within the equipment’s limits, similar products can share the same equipment; customizing multiple sets of molds expands the production range.

3. Intelligent Operation and Real-Time Monitoring

Equipped with a PLC and touch interface, it can simultaneously memorize multiple sets of parameters and monitor key indicators such as winding speed, tension, and number of turns in real time. Operation is simple and debugging is convenient, allowing even inexperienced personnel to quickly learn. For example, the touch interface allows for one-click switching of winding programs for different stator models, reducing changeover time.

4. Durability and Low Maintenance Costs

Key components (such as ball screws and guide rails) are made of highly wear-resistant materials, with a lifespan of tens of thousands of hours, reducing downtime for maintenance. The fully enclosed protective design prevents wire dust leakage, meeting environmental standards and extending equipment lifespan.

5. Customized Development Capabilities

Customized services are available for stator parameters exceeding the standard range (such as special slot shapes and non-standard dimensions). By upgrading the servo system and sensors, higher accuracy (such as ±0.005mm) can be achieved to meet the production requirements of high-end model aircraft motors.

How accurate are brushless model aircraft stator winding machines? What are their technological advantages? Vacuz has provided a simple explanation above; we hope this information is helpful!