The flexibility and compatibility of motor stator automatic winding machines are their core capabilities for adapting to diverse production needs. These capabilities are primarily reflected in equipment design, functional configuration, software control, and service support. Below, Vacuz analyzes these capabilities from the perspectives of specific technical implementation and production applications, hoping to be helpful!

I. Technical Demonstrations of Flexibility and Compatibility

1. Quick Mold and Tooling Changeover

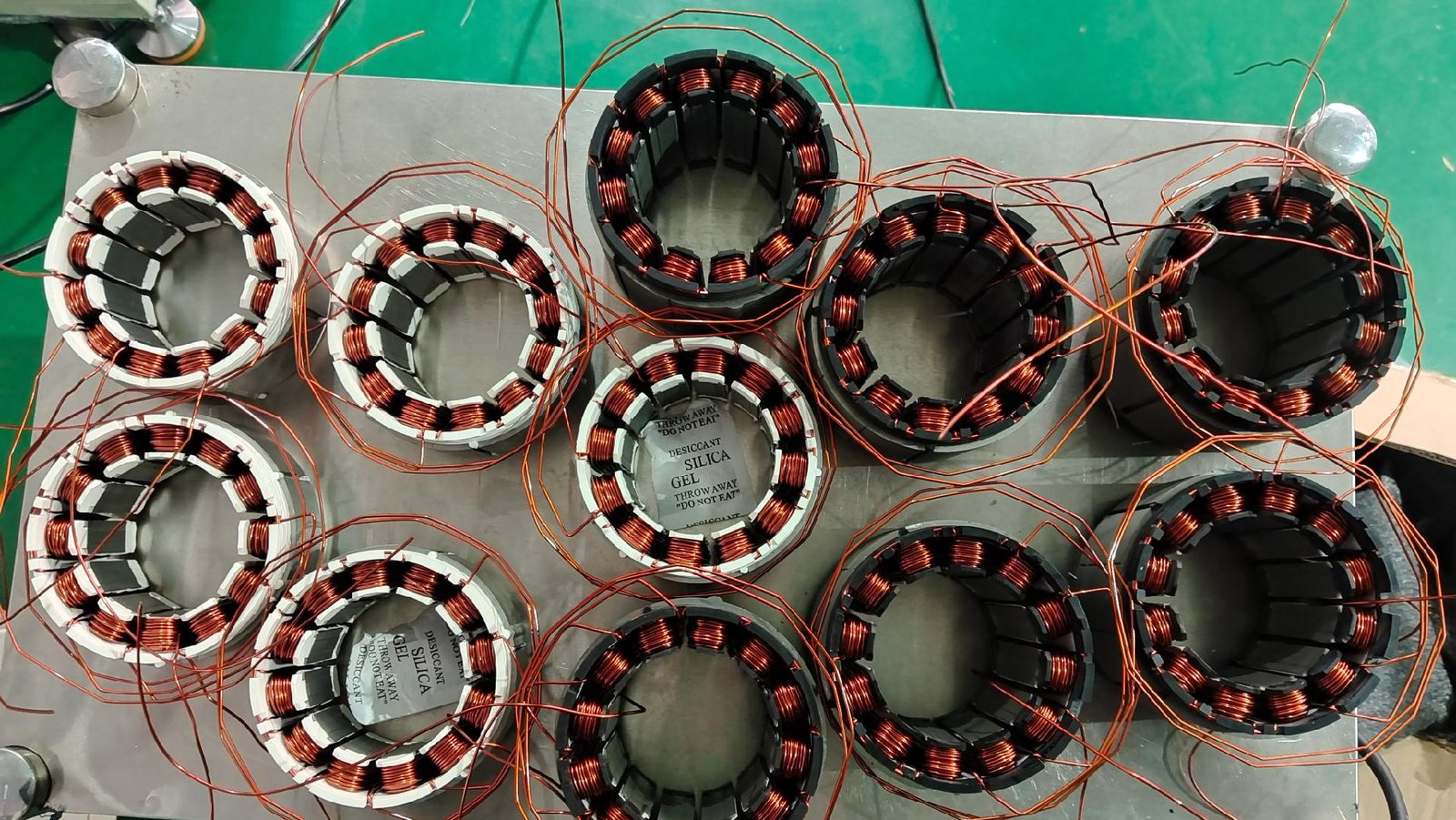

Modular Design: The machine utilizes a modular structure, including removable winding molds, fixtures, and positioning devices. By replacing these modules, it can adapt to stators of varying sizes and slot configurations. For example, for stators with widely varying outer diameters (e.g., 10mm to 100mm), quick changeover is achieved by simply replacing the mold.

Quick Mold Changeover Tools: Equipped with specialized mold changeover tools (such as pneumatic quick-change chucks and electric screwdrivers), these tools reduce manual operation time. Some high-end machines support “one-click mold changeover,” automatically adjusting mold position and parameters via pre-set programs.

Compatibility Design: Mold design incorporates universality, such as the use of standard interfaces or adjustable dimensions, enabling the same mold to accommodate a variety of stator models, reducing mold inventory costs.

2. Adaptive Parameter Adjustment

Intelligent Parameter Library: The device features a built-in parameter library that stores winding parameters (such as wire diameter, number of turns, winding tension, and wire spacing) for different stator models. Operators select a model via the touchscreen or a barcode scanner, and the device automatically retrieves these parameters, reducing manual debugging time.

Dynamic Tension Control: A servo motor drives the winding spindle, combined with real-time feedback from a tension sensor, to automatically adjust winding tension. For example, tension is reduced when winding thin wire (e.g., 0.05 mm) and increased when winding thick wire (e.g., 1.0 mm) to prevent wire breakage or loose coils.

Wire Path Optimization: An algorithm automatically calculates the appropriate wire path to accommodate stators with different slot numbers and slot types. For example, for 6-slot, 12-slot, or 24-slot stators, the device automatically adjusts the winding order and slot spacing.

3. Multifunctional Winding Head Design

Adjustable Winding Head: The winding head supports angle, height, and span adjustments to accommodate both inward-facing (slots facing inward) and outward-facing (slots facing outward) winding requirements. For example, the needle winding head can switch winding direction via a rotating mechanism, while the flying fork winding head can adjust the cross-slot distance via a slide rail.

Multi-wire Parallel Winding Support: The winding head is equipped with multiple slots or nozzles, allowing simultaneous winding of multiple enameled wires (such as two-wire and three-wire parallel winding), meeting the needs of high-power motors.

Special Winding Processes: Some equipment supports complex processes such as layered and segmented winding by replacing winding head accessories (such as splitter plates and wire clamps).

4. Software and Control System Upgrade

Open Programming Interface: The equipment supports secondary development via PLC or industrial computers, allowing users to customize winding programs and adapt to non-standard stator production.

Remote Monitoring and Debugging: Equipped with an IoT module, it enables remote parameter modification, fault diagnosis, and program updates. For example, if parameter deviations are discovered during production, technicians can remotely adjust the equipment via mobile phone or computer.

Data Traceability: The equipment records winding parameters, production time, and operator information for each stator batch, supporting quality traceability and process optimization.

II. Specific Measures to Adapt to Multi-Variety Production Demands

1. Production Process Optimization

Small-Batch Mixed Production Mode: Rapid changeover and parameter switching enable continuous production of small batches of multiple stators.

Flexible Production Line Layout: Integrate winding machines with subsequent processes (such as varnishing and assembly), enabling automated stator flow via AGVs or conveyor belts, reducing manual handling and waiting time.

2. Personnel Training and Simplified Operations

Visual Operation Interface: A touchscreen or tablet computer provides a graphical interface to guide operators through changeovers, parameter settings, and troubleshooting. For example, the device displays a 3D model of the stator, annotating key dimensions and winding paths.

Standardized Operational Procedures: Develop changeover SOPs (Standard Operating Procedures) that clearly define the steps for mold changes, parameter calls, and first-article inspection, reducing operational complexity.

Multi-Skilled Worker Development: Operators are trained to master various stator winding processes to enhance production line flexibility. For example, a single worker can simultaneously operate both internal and external winding equipment.

3. Equipment Maintenance and Spare Parts Management

Preventive Maintenance: Sensors monitor equipment operating conditions (such as vibration and temperature) to provide early warning of potential failures and reduce downtime. For example, when a winding shaft bearing is worn, the system prompts a replacement.

General Spare Parts Inventory: Stock commonly used, high-consumption spare parts (such as winding nozzles and tension springs) to shorten maintenance cycles. For example, the same winding nozzle model can be compatible with multiple equipment.

Remote Technical Support: Establish a rapid response mechanism with equipment suppliers to provide on-site repair guidance via video calls or augmented reality (AR).

III. Equipment Selection Recommendations

Evaluate Production Diversity: Analyze the number of stator models, size ranges, and process complexity currently and potentially in the future, and select equipment with strong compatibility.

Investigate Changeover Efficiency: Require suppliers to demonstrate the mold change and parameter call process, and record actual changeover time.

Verify Software Functionality: Test the equipment’s parameter library management, remote control, and data traceability capabilities to ensure they meet production management requirements.

Focus on After-Sales Service: Select suppliers that offer rapid response, spare parts supply, and technical training to reduce long-term operating costs.

How can motor stator automatic winding machines demonstrate flexibility and compatibility? How can they adapt to the demands of multi-product production? Vacuz has provided a brief explanation above, hoping it will be helpful!

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]