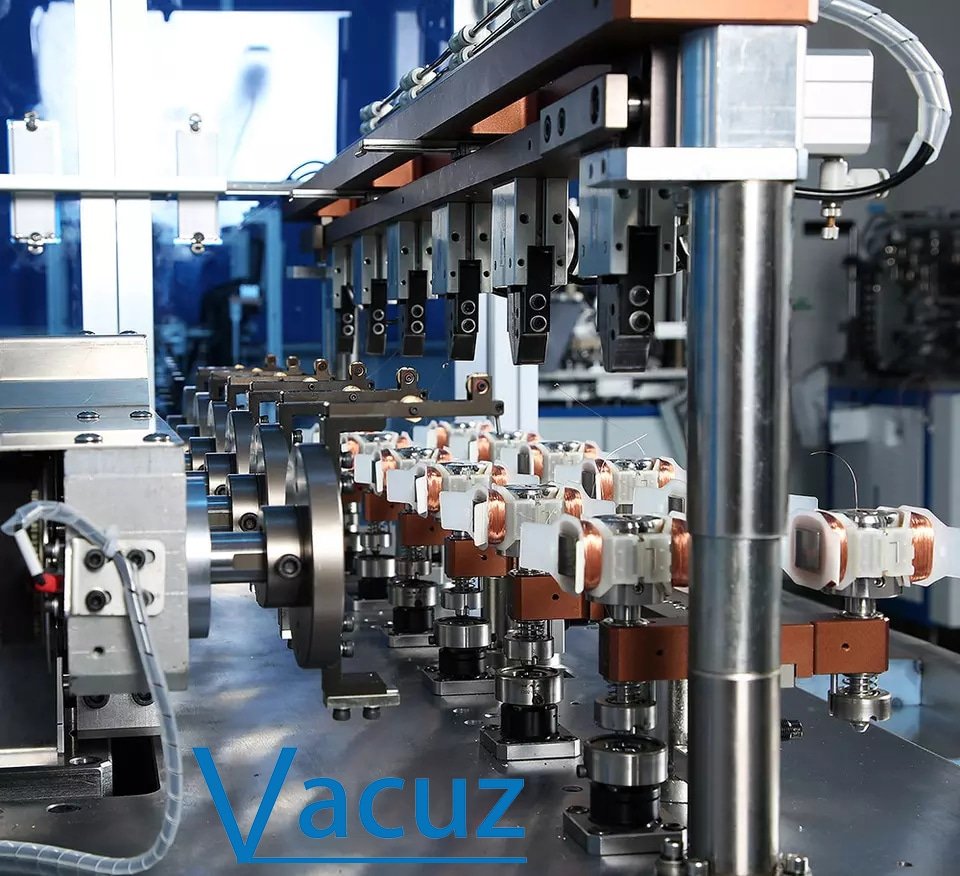

When pursuing the winding accuracy and wire arrangement effect of the fully automatic stator precision winding machine, we do need to comprehensively consider and optimize from multiple dimensions such as equipment configuration, process parameters, operation and maintenance. The following is Vacuz’s in-depth analysis and expansion of relevant content:

Cooling fan motor

Equipment hardware and configuration optimization:

1. Improve the accuracy of mechanical components

1. Core component processing: It is crucial to ensure the processing accuracy of core components such as guide rails, screw rods, and spindles. This requires us to strictly screen suppliers when purchasing and select manufacturers with high-precision processing capabilities. At the same time, these components are regularly inspected and maintained to ensure that they are always in good working condition.

2.High-precision mold design: The accuracy of the mold directly affects the dimensional consistency of the stator core slot. Therefore, it is indispensable to use high-precision CNC machine tools for mold processing. In addition, the material selection of the mold also needs to consider wear resistance and hardness to ensure stability under long-term use.

2. Select high-quality electrical components

1. Servo motor and encoder: The combination of high-precision servo motor and encoder can ensure accurate control of winding speed and position. When choosing, we should give priority to well-known brands, and at the same time, customize the selection according to actual needs to achieve the right performance match.

2. Tension control system: The stability of tension control is crucial to the quality of winding. Equipped with a brand servo tensioner and a closed-loop control strategy, it can achieve dynamic adjustment of tension and ensure the stability of the wire during winding.

Process parameters and operation optimization

III. Accurately set winding parameters

1. Winding speed and tension: Depending on the wire diameter and stator specifications, we need to fine-tune the winding speed and tension. This usually requires multiple tests and data analysis to determine the parameter combination.

2. Wire spacing and width: Reasonable wire spacing and winding width settings can avoid winding or crossing problems caused by too long or too short wire harnesses. In actual operation, we should make flexible adjustments based on the stator size and wire characteristics.

Fourth, optimize the coordination between the wire arrangement mechanism and the mold

1. Adjustment of the wire arrangement wheel and the wire clamp: Ensuring the positioning accuracy and verticality of the wire arrangement wheel and the wire clamp is the key to improving the wire arrangement effect. This requires us to perform strict calibration work during the equipment installation and commissioning phase, and regularly check and maintain it during daily use.

2. Enhanced mold rigidity: Using high-strength materials to manufacture molds can effectively avoid deformation problems during the winding process. At the same time, the design of the mold also needs to consider easy replacement and maintenance to improve production flexibility.

Five, Environment and Maintenance Management

1. Constant temperature and humidity workshop: Maintaining stable temperature and humidity in the workshop is crucial to the quality of winding. This requires us to invest in necessary temperature control and humidity control equipment in the workshop construction, and regularly calibrate and maintain it.

2. Shock and noise reduction measures: Installing shock-absorbing pads and other shock-absorbing measures at the bottom of the equipment can reduce the impact of vibration on winding accuracy. At the same time, reasonable noise reduction design can also improve the working environment of operators.

Six, regular maintenance and care

1. Key component inspection: Regular inspection and replacement of key components such as winding nozzles, wire wheels, tension devices, etc. is an important measure to ensure the long-term stable operation of the equipment.

2. Equipment cleaning: Keeping the surface and interior of the equipment clean is essential to prevent dust or debris from affecting the winding quality. This requires us to develop good cleaning habits in daily use and perform deep cleaning regularly.

Seven, debugging and monitoring

1. Manual operation test: Manual testing before formal winding can ensure that the running path of components such as nozzles and needle bars is normal and the positioning is accurate. This helps us to discover and correct potential problems in a timely manner.

2. Program optimization: Program according to the winding diagram, or import the program to call directly, and achieve a good state through gradual adjustment. This requires us to pay attention to details and precision during the programming process to ensure the accuracy and reliability of the program.

Real-time monitoring and automatic adjustment

3. Sensor monitoring: Using sensors to monitor parameters such as position, tension, and speed in real time can ensure the stability of winding accuracy. This requires us to consider the accuracy and stability of the sensor when selecting the equipment, and to calibrate and maintain it regularly during daily use.

4. Automatic detection system: The introduction of an automated detection system can monitor the quality of the wiring in real time, and promptly detect and correct deviations. This can not only improve production efficiency, but also reduce the scrap rate and improve overall economic benefits.

더블 스테이션 냉각 팬 모터 코일 자동 BLDC 브러시리스 드론 외부 고정자 플라잉 포크 와인딩 머신 장비 판매

In summary, through comprehensive optimization from multiple aspects such as equipment configuration, process parameters, operation and maintenance, we can significantly improve the winding accuracy and wiring effect of the fully automatic stator precision winding machine. I hope these suggestions can provide useful reference and reference for your actual work.

이메일: sales@vacuz.com