To evaluate the quality and technical compliance of a stator winding machine, a comprehensive assessment is needed across five dimensions: core performance, equipment configuration, safety and stability, production efficiency and intelligence, and after-sales service and technical support. Below, Vacuz will briefly introduce the specific evaluation criteria.

I. Core Performance Indicators

1. Winding Accuracy

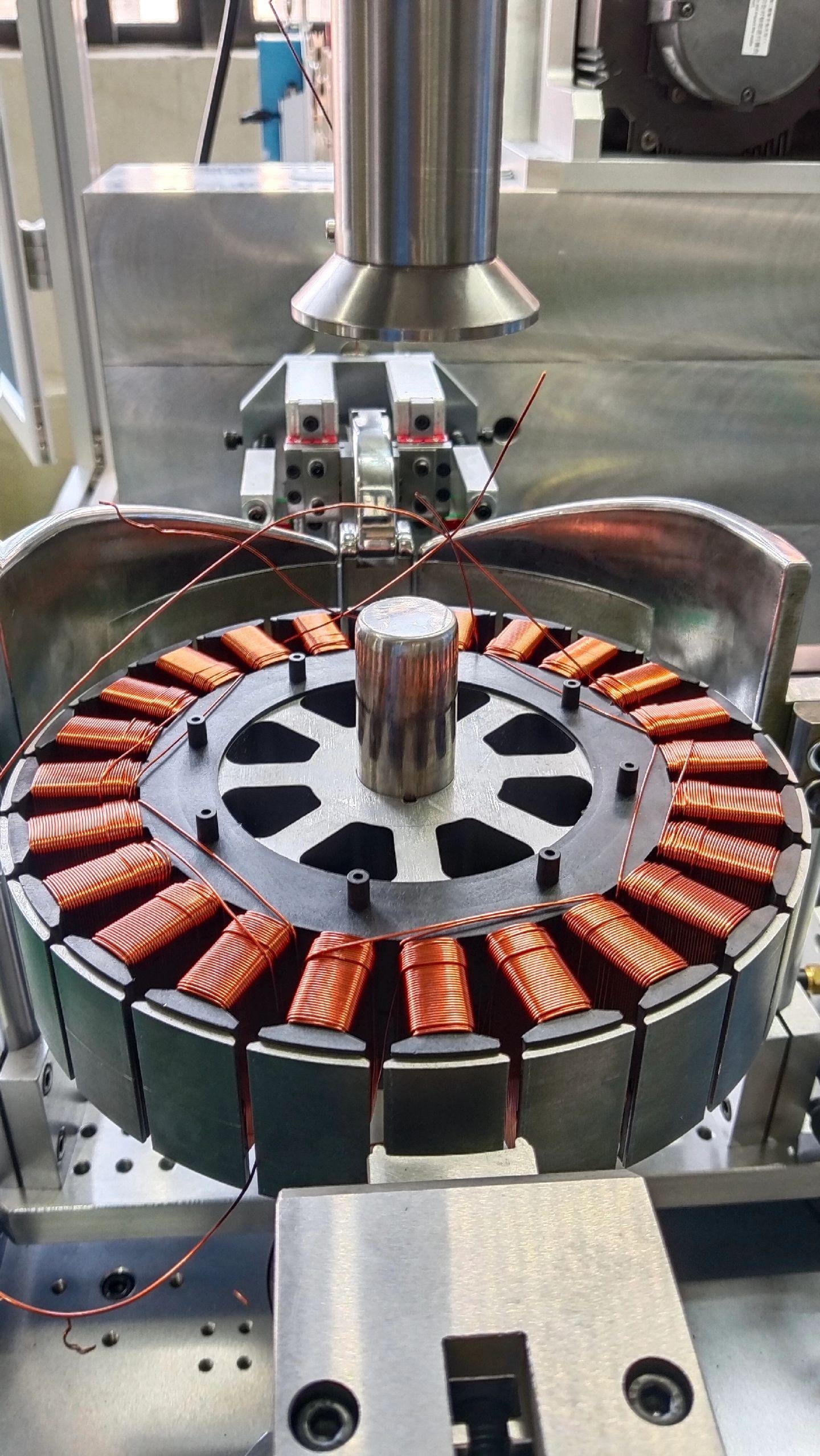

Coil Parameter Control: Accurate control of parameters such as the number of turns, layers, wire spacing, and position is required to ensure tight coil arrangement and high consistency. For example, high-precision equipment can achieve a winding error of ±0.01mm, avoiding motor performance degradation, poor stability, or fractures and short circuits caused by uneven stress distribution within the coil due to insufficient precision.

Detection and Verification: Electrical testing of the windings is performed through an automatic detection system, monitoring the winding process in real time to ensure that electrical performance meets requirements.

2. Winding Speed

High-Speed Winding Capability: High-speed winding machines require a high-strength drive system, optimized mechanical structure, and a high-precision servo motor to balance speed and stability. For example, the stator winding of a 110,000 RPM high-speed blower motor requires a four-station or six-station internal winding machine. The six-station machine offers higher production efficiency, but the cost is correspondingly higher.

Speed Stability: During no-load operation testing, the equipment must maintain a stable and compliant speed to avoid deterioration in winding quality due to speed fluctuations.

3. Scope of Application

Multi-Specification Compatibility: The equipment must support stator winding of multiple specifications, possessing high flexibility and adjustability. For example, the stator outer diameter of brushless micro-winding equipment typically requires a range of Φ20~Φ130mm, and the inner diameter between Φ12~Φ100mm. Items exceeding this range require non-standard customization.

Stack Thickness Adaptability: The stator stack thickness (height) is generally required to be controlled within a certain range. The equipment needs to adjust the pin oscillation method and wire guide method according to the stack thickness to avoid problems such as wire scraping, damage, and breakage.

II. Equipment Configuration and Materials

1. Key Component Configuration

Servo Motor and Drive Control: High-precision servo motors and drive systems are the core of high-speed winding, requiring fast response and high control accuracy.

Guide Rails, Lead Screws, and Belts: These components directly affect the motion accuracy and stability of the equipment, requiring high-precision, wear-resistant materials.

Cylinders, Couplings, Needle Bars, Wire Nozzles, and Tensioners: Appropriate specifications must be selected based on wire diameter and winding method.

2. Material Quality

Metal Materials: High-quality winding machines are typically made of high-quality metal materials to ensure equipment stability and durability.

Insulation and Lubrication Materials: Must meet relevant standards to ensure operational safety and efficiency.

III. Safety and Stability

1. Safety Performance

Safety Control System: Equipped with overload protection devices, emergency stop buttons, etc., to prevent operator injury.

Insulation and Grounding Measures: Outer insulation and grounding must meet standards to avoid leakage risks.

2. Operational Stability

Long-Term Operation Testing: The equipment must remain stable during long-term operation to avoid malfunctions or errors. For example, during no-load operation tests, bearings and moving parts must not overheat or produce abnormal noise.

Failure Rate and Maintenance Costs: Reliability assessments must consider the stability of the mechanical structure and electrical system. Low-failure-rate equipment reduces production line downtime and maintenance costs.

IV. Production Efficiency and Intelligence

1. Production Efficiency

Output per Unit Time: Measured in hours or shifts, differences between product types must be considered.

Yield Rate: Yield Rate = (Number of Good Products / Total Production Quantity) × 100%. A high yield rate reflects stable equipment operation and reasonable parameter settings.

Overall Equipment Effectiveness (OEE): OEE = Time Utilization × Performance Efficiency × Quality Rate. The closer the value is to 100%, the higher the efficiency.

2. Intelligence Level

Intelligent Control System: Equipped with PLC or industrial computer control to implement complex control logic and algorithms.

Sensors and Detection Systems: Tension sensors, position sensors, etc., monitor winding parameters in real time to ensure quality and stability.

Additional Functions: Automatic counting, fault diagnosis, remote monitoring, and other functions can improve the level of intelligence and production efficiency.

V. After-Sales Service and Technical Support

1. After-Sales Service Policy

Warranty Period: A longer warranty period means the manufacturer assumes more responsibility, and the equipment price may be higher.

Repair Response Time: Rapid response and on-site repair capabilities ensure the equipment is restored to operation promptly.

2. Technical Support Capabilities

Operation Training: The manufacturer must provide equipment operation training to help users quickly get started.

Technical Support: Resolving problems encountered by users during use and improving equipment efficiency.

How to assess whether the quality and technology of a stator winding machine meet requirements? What are the judgment criteria? Vacuz has provided a simple explanation above, and we hope this information is helpful!