Permanent magnet motor rotor, is an important part of the motor, for permanent magnet motor rotor assembly, is a troublesome problem, there are many spare parts need to be assembled according to a certain order, ordinary labor certainly can not, so you need to use a professional automated production line equipment, so what are the design and details of the permanent magnet motor rotor assembly production line? Vacuz to analyze it!

Permanent magnet motor rotor assembly line design and details need to consider the following aspects.

1. Layout of the production line: According to the production needs and site conditions, the layout of the production line is reasonably planned to ensure that the production line is smooth and efficient.

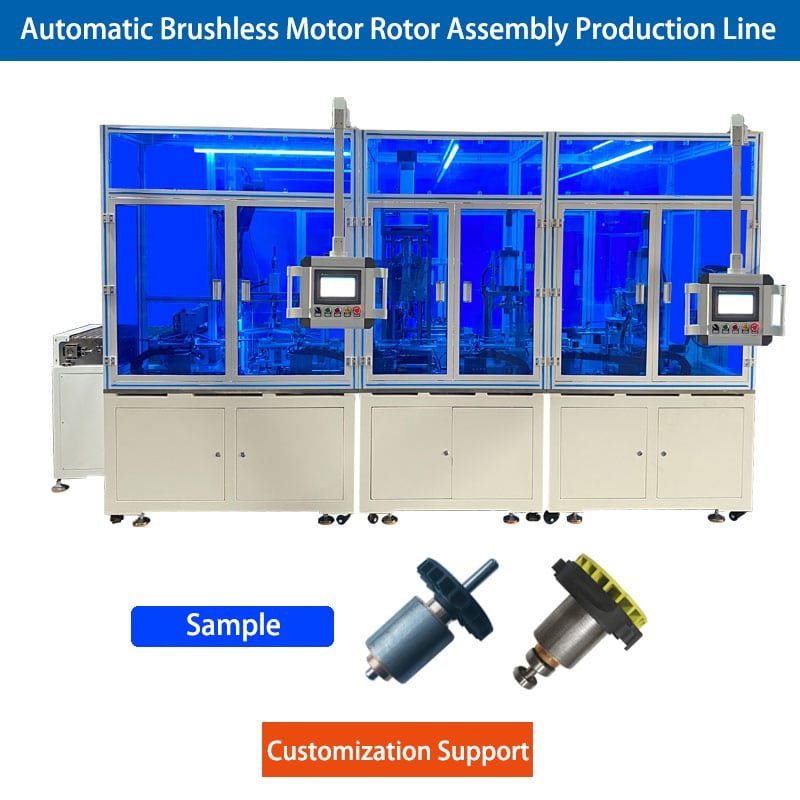

2. Equipment selection: According to the production process and requirements of the motor rotor, select the appropriate assembly equipment, such as rotor assembly equipment, magnet steel assembly equipment.

3. Degree of automation: Consider the introduction of automated equipment to improve production efficiency and quality and reduce manual errors.

4. Quality inspection: Set up quality inspection links in the production process to strictly control the quality of motor rotor and ensure that the product meets the quality standards.

In terms of details, the following points can be considered.

1. Equipment parameter setting: According to the specifications and requirements of the motor rotor, set the equipment parameters reasonably to ensure that the equipment can accurately and efficiently complete the assembly task.

2. Material management: Establish a perfect material management system to ensure timely and accurate supply of materials to avoid material problems affecting production progress.

3. Personnel Training: Train the operators on the production line to improve their operating skills and safety awareness to ensure the normal operation of the production line.

4. Maintenance: Regularly maintain the equipment on the production line to ensure that the equipment is in good working condition and prolong the service life of the equipment.

What are the design options and details of permanent magnet motor rotor assembly line? In addition to the need to comprehensively consider the production requirements, site conditions, equipment selection, etc., but also consider automation, quality inspection, etc., in order to ensure the efficient and stable operation of the production line.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]