The operating principle and ideas of safety protection equipment for winding machine manufacturers

1) High efficiency, no additional loss during speed regulation. 2) Wide use scale, can be used for cage type asynchronous motor. 3) Large speed regulation scale, hard characteristics and high precision. Therefore, this study selects the frequency conversion speed control method.

3, the basic composition of the winding machine system

Z initial planning of the system mainly consists of 51 microcontroller Z small system, photoelectric blocking relay module and infrared digital obstacle avoidance sensor. Among them, 51 microcontroller Z small system includes: power supply, external crystal circuit, reset circuit and STC89C52 chip, later through practice, the choice of logic control module more accurate. The protection equipment mainly consists of infrared digital obstacle avoidance sensor, logic control module and relay speed reduction module.

When the operator’s hand enters the risk area, the infrared digital sensor reacts the detected signal to the logic control module, and the logic control module outputs the corresponding control signal to the relay speed reduction module according to the reacted signal, and the relay speed reduction module connects different resistance value resistors in series into the foot pedal speed control circuit to reduce the speed of the winding motor and then play a safety protection role.

As the winding machine speed is too fast, workers need to be very fast and skillful action to operate, then there are 2 kinds of finger injury phenomenon: 1) has broken the enameled wire broken.

1) The broken enameled wire break will pierce into the finger, resulting in finger injury.

(2) high-speed operation of the copper wire will be pressed to the finger, the lighter finger skin out, the heavier broken fingers.

1、 Frequency converter operating principle

The operation principle of communication frequency converter is: frequency conversion technology is a technology to change the frequency of power supply through frequency converter, and then change the speed of communication asynchronous motor. Through the inverter first to communicate to DC change, and then through the inverter to DC to communicate change, and then control the speed of the communicating motor. The control of the inverter for this project is to manipulate the frequency of the inverter output power by manipulating the imitation voltage of the input inverter, so that the rotational speed of the communicating motor will change with the change of the output power frequency.

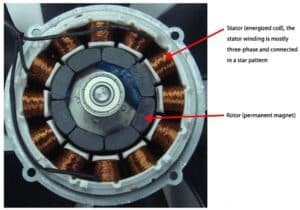

2、 Three-phase asynchronous motor inverter speed control

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]