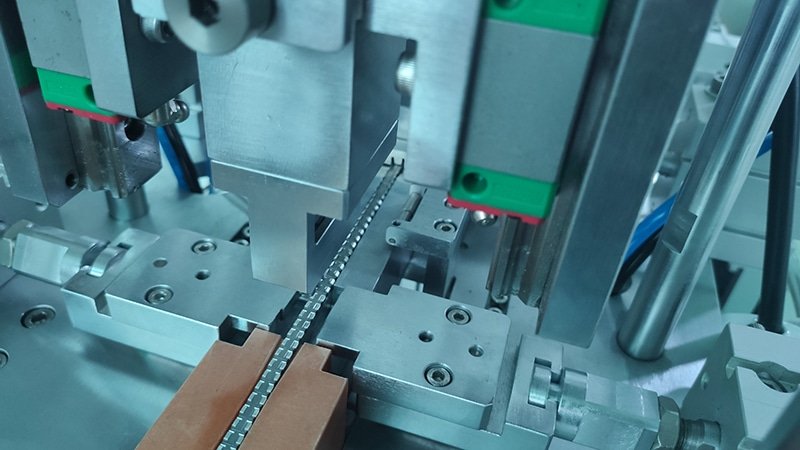

1, fine displacement transmission arrangements: automatic winding machine equipment, there are many fine displacement parts, equipment use in the process of these parts are in a state of wear and tear, equipped with high-precision ball screws and guide rails greatly enhance the accuracy of the displacement parts of the winding machine, extend the life of these wear parts.

2, low energy consumption, low noise arrangement equipment: with the implementation of energy saving and emission reduction in various industries, less power consumption models will become the mainstream product line, manufacturers in the planning has been focusing on the selection of electrical parts, through the use of new technologies to reduce the energy consumption of the equipment, a variety of vibration-damping arrangements for the equipment and the use of low-noise arrangements in the automatic coil winding machine so that equipment for the operation of the noise has been effectively reduced.

3, more intelligent servo drive system and sensing technology: servo drive system was first used in the fine CNC lathe, followed by the winding machine precision requirements of the constant trekking, the use of servo systems can trek winding equipment spindle and line arrangement of precision, trekking the processing of the coil of the whole line of the degree of winding.

Automatic winding machine equipment and use of the environment

1. The working platform and foundation of the winding machine should have satisfactory strength and rigidity to prevent the winding machine from oscillating violently when moving at high speed, to ensure that the oscillation of the winding machine does not affect the accuracy and longevity of the machine and does not affect the quality of the coils, and that the equipment and buildings close to the winding machine should not have any adverse effect on the winding machine.

2. The working platform and foundation of the winding machine should have stability and durability, waterproof and anti-slip and harmful objects of erosion, to ensure that there is no deformation or part of the subsidence. When the winding machine is placed in the environment that may suffer from chemical liquid, oil or corrosion, the foundation should be added protective layer. For example, in the surface of the foundation coated with acid-proof, oil-proof cement mortar sand, and set up liquid discharge, set liquid groove.

3. The foundation of large winding machine should be pre-pressurized before the machine equipment. Pre-pressure of the quality of the total mass of the winding machine and the customer workpiece maximum mass sum of 1.25 times. Pre-pressurized material can be steel, sand and small stones. The pre-compressed material should be evenly pressed on the foundation to ensure that the foundation sinks evenly . Pre-pressure operation should be carried out until the foundation no longer continue to sinking suspension.

4. Winding machine work station and foundation is necessary with the type of winding machine base to adapt, and can ensure that the equipment on the winding machine robust and reliable, to ensure that there is a reliable grounding around the equipment, to ensure that there is no major sources of interference around.

5. The center of gravity of the winding machine and the total center of gravity of the working platform and foundation should be located in the same vertical line with the centripetal force of the foundation surface.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]