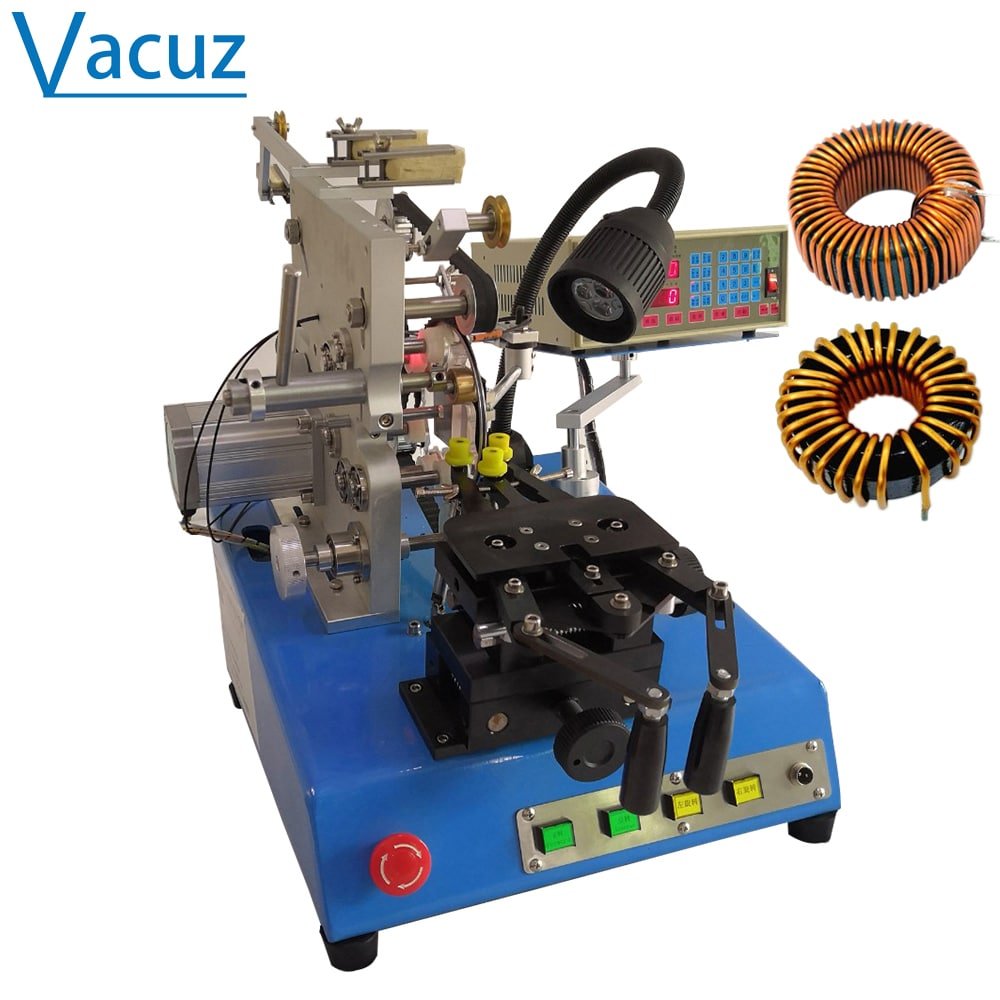

toroidal coil inductor winding machines just mechanical components can not complete the winding operation, but also need to have the cooperation and control of the electrical control system to achieve the operation of the machine, then obviously the control system is very important to the performance of the winding equipment, at present we have the following common control systems: the following categories.

A. PLC + 텍스트 디스플레이

이러한 유형의 제어 시스템은 종종 모델의 높은 요구 사항 및 특수 요구 사항에 사용되며 서보 모터와 PLC 제어는 고정밀 모션 제어를 달성 할 수 있으며 권선 장비의 서보 시스템은 기존 스테퍼 모터의 정확도보다 훨씬 높은 고정밀 권선 작업을 완료하여 미세 라인의 장비와 고속 작동 안정성이 강화되어 이러한 유형의 구성 조합은 종종 고급 모델에서 발견됩니다.

둘째, CNC 특수 컨트롤러

CNC controller was first introduced in Taiwan’s winding equipment, after several generations of model development plus domestic manufacturers to improve and upgrade the CNC winding controller, this type of automatic winding machine controller with full functionality, stability and many other advantages, is a common configuration of the current mainstream models.

3, 프로그래밍 가능한 컨트롤러

Four, we commonly use transformer winding machine is programmable controller, this type of controller generally has the number of turns preset, speed control, step sequence settings and other functions, the controller generally uses a single-chip computer as the control core, but also the most subdivided types of control systems

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]