With the continuous development of technology, the number of winding machine manufacturers and related technologies is increasing. Different manufacturers use different technologies, resulting in varying equipment quality. So, what are the characteristics of a high-quality brushless motor winding machine manufacturer? What are the requirements for producing a winding machine? Below, Vacuz will give you a brief introduction!

I. Core Characteristics of a High-Quality Brushless Motor Winding Machine Manufacturer

1. Technology-Driven R&D System

High-quality manufacturers generally establish multi-axis collaborative systems based on servo control technology, using internationally renowned servo motors and controllers to achieve a winding accuracy of ±0.01mm. For example, Vacuz uses PLC closed-loop control and real-time feedback from tension sensors to ensure consistent wire tension and avoid the risk of wire breakage. This technology supports the winding of micro to medium-sized motors with wire diameters of 0.08-1.3mm, covering diverse needs such as DC brushless motors and stepper motors.

2. Modular and Flexible Production Capabilities

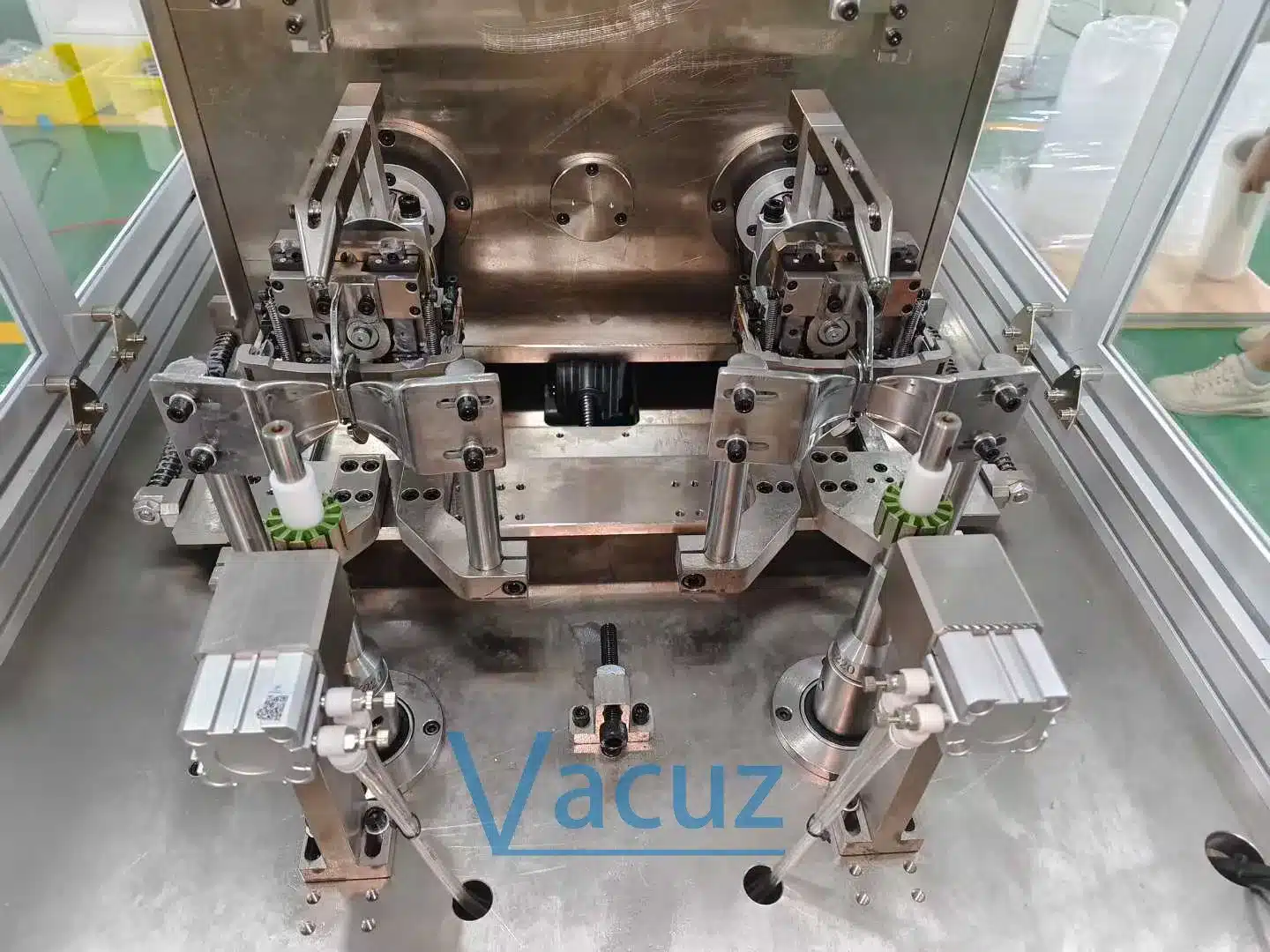

Leading companies adopt modular fixture designs, supporting rapid changeover (changeover time ≤ 10 minutes), reducing mold costs and downtime.

Leading manufacturers integrate loading/unloading, winding, and wire arrangement functions. Through industrial cameras and AI algorithms, the winding path is automatically corrected, and IoT vibration sensors provide early warning of wear on key components, enabling preventative maintenance.

3. Cross-Series Compatibility and Non-Standard Customization

High-quality manufacturers achieve universal stator molds within the same series by adding shims or auxiliary parts, allowing equipment sharing across product series. For stator parameters exceeding the range, segmented winding processes and dynamic speed regulation are provided.

II. Production Requirements for Brushless Motor Winding Machines

1. Mechanical Structure and Material Standards

Frame Design: Utilizes a composite structure of sheet metal and aluminum profiles, providing strong shock absorption and low vibration at high speeds (no-load speed up to 1200 RPM).

Key Components: Precision guide rails, lead screws, tensioners, and other accessories increase rigidity by 30%, reducing vibration. For example, Vacuz’s fly fork head adopts a lightweight design and pneumatic balance, increasing speed to 1200 RPM.

Low Noise Optimization: Operating noise is controlled within a reasonable range through mechanical structure improvements.

2. Mold and Process Precision

Mold Machining: Strictly manufactured according to drawings, with tolerances controlled within micrometers. Surface polishing avoids scratching the enameled wire.

Winding Consistency: High-precision servo motor + PLC closed-loop control ensures appropriate wire tension.

Dynamic Compensation: Automatically adjusts the wire spacing after inputting the actual stack thickness, reducing sway radius.

3. Safety and Maintenance System

Low-Speed Start-up: Initial 50-80 RPM to fix the wire end, reducing the risk of wire breakage.

Automatic Lubrication System: Quantitative pump + nozzle timed lubrication avoids human error.

Early Warning Function: Vibration sensors warn of wear on key components; cloud-based analysis of maintenance needs automatically generates maintenance plans and records fault history.

4. Multi-Station and Composite Functions

Station Layout: Dual-station to six-station design reduces idle time; six-station batch production significantly improves efficiency.

Composite Winding Machine: “Flying fork + needle type” compatible with both internal and external winding needs; changeover time is only 10 minutes.

High-quality brushless motor winding machine manufacturers need to possess three core capabilities: technology-driven development, modular production, and full-process automation, while simultaneously meeting production requirements such as mechanical precision, process control, and safety maintenance. Leading companies have achieved compatible production of over 80% of stator products through technologies such as servo control, composite workstations, and non-standard customization, significantly improving industry efficiency and quality stability.