Brushed and brushless motors are two common motor types, and their stator winding methods differ. Using the appropriate winding machine ensures the proper function of the winding process. So, what are the differences between brushless and brushed stators wound using a fully automatic motor winding machine? How should one choose the right equipment? Vacuz will briefly explain this below!

I. Core Differences Between Brushless and Brushed Stator Winding

1. Structure and Winding Location

Brushed Motors:

The winding is performed on the rotor, requiring winding across the slots. Care must be taken to avoid wire damage and breakage. The structure is relatively simple, and traditional winding methods are easy to operate. The winding process is mature and stable, and the equipment requirements are primarily basic, resulting in low costs.

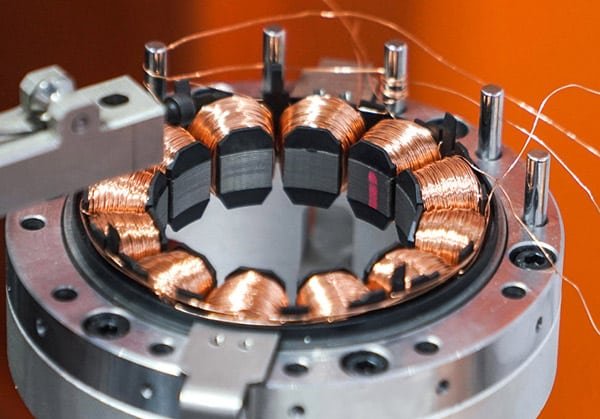

Brushless Motors:

The winding is performed on the stator, with either internal winding (with the slots facing inward) or external winding (with the slots facing outward). These require higher equipment precision and configuration, and the winding process is more complex. Internal Winding: Utilizes a pin-type winding machine, requiring high-precision guide rails and a servo control system, requiring high configuration requirements and achieving more precise winding.

External Winding: Utilizes a flying fork winding machine, achieving speeds exceeding 2900 rpm and suitable for applications such as model aircraft and drones. It offers high efficiency but requires less configuration than internal winding.

2. Differences in Performance Requirements

Brushed Motor: Offers fast response and high starting torque, suitable for applications with low speed control and environmental requirements.

Brushless Motor: Offers low noise, low interference, and long life, suitable for applications requiring high precision and environmental requirements. However, this comes at the expense of higher equipment costs and maintenance requirements.

II. Key Considerations for Selecting Brushless Stator Winding Equipment

1. Stator Slot Orientation

Inward-facing Slots: Choose a pin-type winding machine, suitable for internal winding applications such as pumps, hair dryers, and power tools. It offers high configuration requirements and precise winding.

Outward-facing Slots: Choose a flying fork winding machine, suitable for external winding applications such as model aircraft motors, fascia guns, and drone motors. It offers high efficiency and wide coverage.

2. Stator Dimensions

Outer Diameter: Select the number of workstations (e.g., two, four, or six) based on the stator’s outer diameter. The smaller the outer diameter, the more workstations you can choose and the faster the winding speed.

Height: For taller stators (such as roller motors), consider the swinging needle and wire feeding methods to avoid increased winding difficulty.

2. Wire Diameter and Winding Method

Wire Diameter: Fine wire (<0.1mm) requires a precision winding machine with controlled tension to prevent breakage. Thick wire (>0.8mm) requires a reduced winding speed to ensure coil tightness.

Multi-Wire Winding: Accurate tension control, synchronized winding capabilities, and a sophisticated wire routing system are required to ensure uniform winding of multiple wires.

3. Equipment Performance and Configuration

Stability: Equipment stability is critical to winding performance, so select a proven, market-proven machine.

Production Efficiency: Select equipment with a winding speed that matches your production scale to avoid efficiency bottlenecks.

Core Configuration: High-end equipment (such as servo control systems and high-precision guide rails) can improve winding accuracy, but the cost needs to be balanced against production requirements.

4. Flexibility and Compatibility

Mold Conversion: Choose equipment with flexible conversion options to minimize production interruptions.

Compatibility: The equipment must be compatible with different stator models to meet the needs of diverse production.

5. Budget and After-Sales Service

Equipment Price: Choose cost-effective equipment based on your budget, avoiding excessive price reduction that may result in insufficient performance.

Manufacturer Strength: Choose a supplier with technical expertise and after-sales support to ensure long-term, stable operation.

III. Key Considerations for Selecting Brushless Stator Winding Equipment

1. Basic Functional Requirements

Brushless motor winding technology is mature, and equipment requirements primarily focus on basic functions. Double-flying fork winding machines can solve cross-slot winding problems.

2. Cost and Maintenance Ease

Brushless motor equipment has a low cost.

3. Easy Maintenance

Suitable for cost-sensitive production scenarios.

4. Match Production Scale

Select equipment efficiency based on production scale. Avoid overcapacity or undercapacity.

What are the differences between brushless and brushed stator winding on fully automatic motor winding machines? How should I choose the right equipment? Vacuz has provided a brief explanation above. We hope this information is helpful!

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]