As the core equipment in the field of motor manufacturing, the importance of brushless stator winding machine is self-evident. So what are the main components of brushless stator winding machine? What are the functions and advantages? Vacuz further expands and deepens the relevant content to present you with a more comprehensive and in-depth analysis.

1. Deepen understanding of core components

1. Mechanical transmission system

a. Servo motor and reducer: As the power source of the winding machine, the coordinated work of the servo motor and reducer ensures the high-precision movement of the winding spindle and the wire arrangement mechanism. Through accurate speed and torque control, the wire is stably and evenly distributed in the stator slot.

b. Precision guide rails and lead screws: The precision design of the guide rails and lead screws not only supports the movement of the wire arrangement mechanism, but also ensures the stability and accuracy of the winding process. Its error is controlled within ±0.01mm, which provides a strong guarantee for high-precision winding.

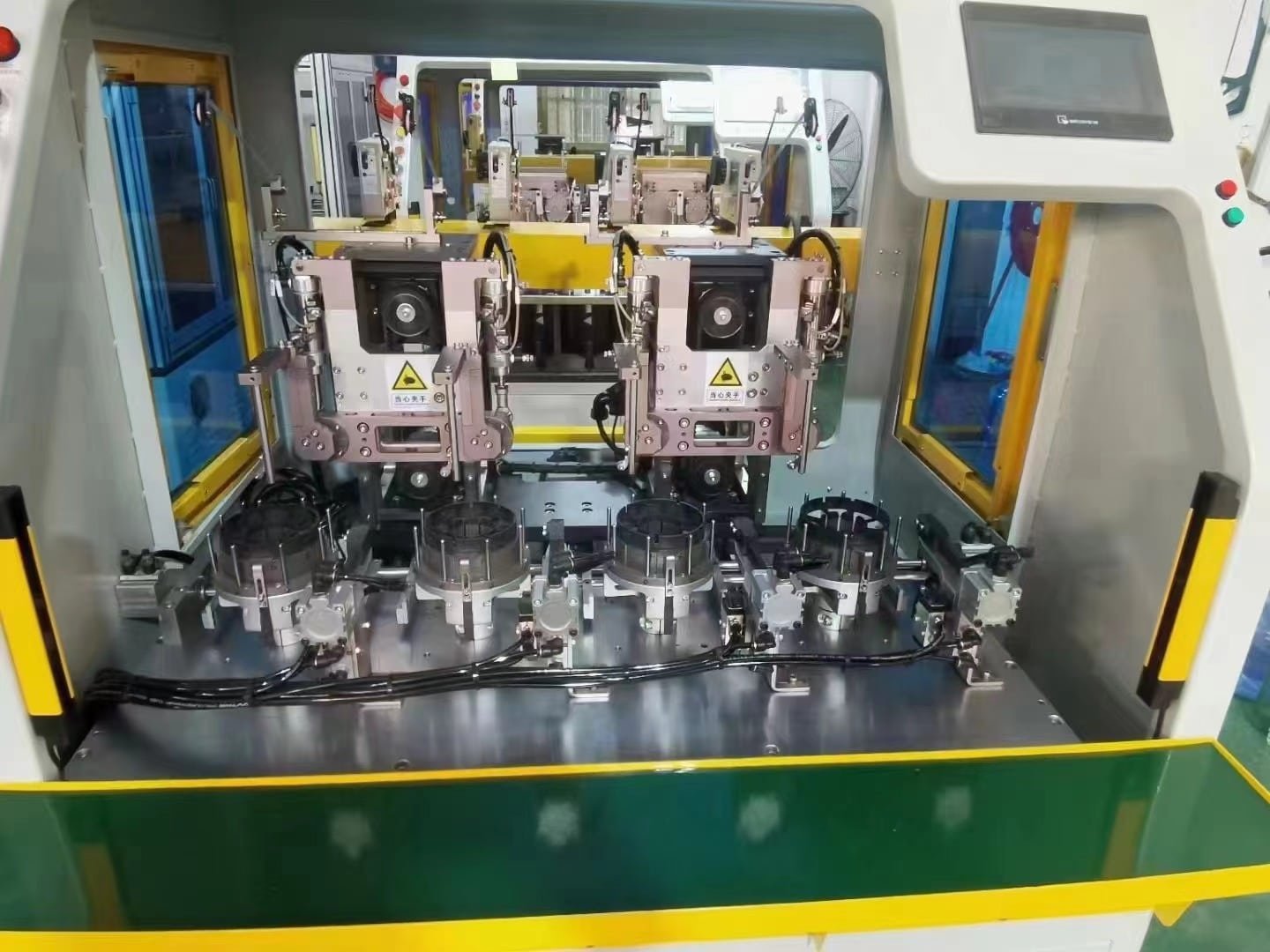

2. Electrical control system

a.PLC/motion controller: As the “brain” of the winding machine, the PLC/motion controller integrates complex winding program logic, supports multi-speed and multi-mode switching, and meets the needs of different motor types and different winding processes.

b. Human-machine interface (HMI): Touch screen operation makes the operation of the winding machine more intuitive and convenient. By presetting process parameters, users can easily realize winding processing of different stator models, while supporting data storage and call, improving production efficiency.

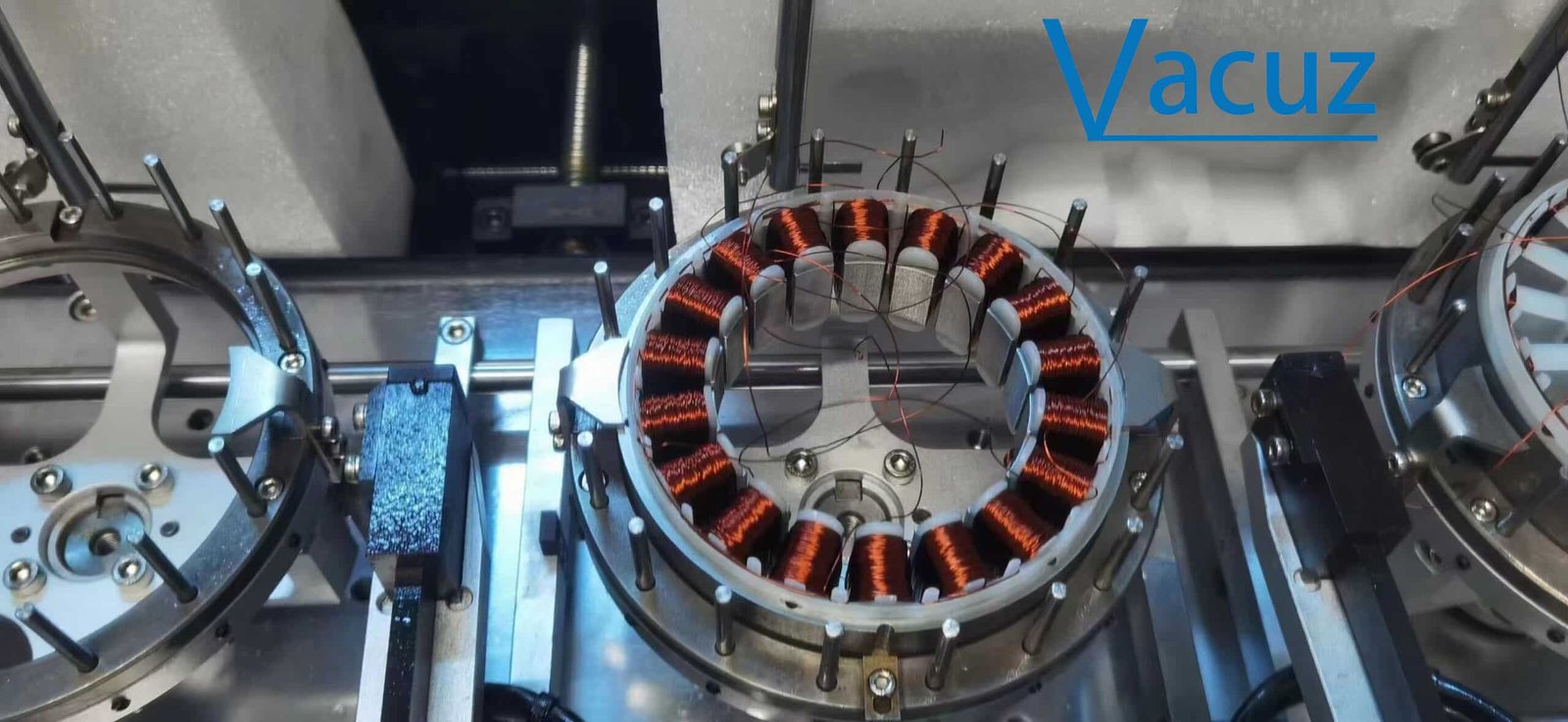

3. Winding actuator

a.Winding spindle: The high-rigidity design ensures the stability and accuracy of the winding process. The ability to adapt to different stator outer diameters allows the winding machine to be used in the production of various motor types.

b. Wire arrangement device: The servo-driven synchronous belt or ball screw realizes the precise axial and radial arrangement of the wire, ensuring the stability and consistency of the winding quality.

2. In-depth analysis of core functions

1. High-precision winding

Through the coordinated movement of the servo motor and the precision guide rail, the winding machine achieves high-precision filling of the wire in the stator slot, reducing the risk of inter-turn short circuit. At the same time, it supports multi-layer winding and automatic insertion of interlayer insulation paper to ensure the electrical performance of the motor.

2. Flexible process adaptation

The programmable winding direction, number of turns and pitch enable the winding machine to adapt to the needs of different motor poles and slot types. At the same time, it supports segmented winding to meet the needs of complex motor design.

3. Efficient and automated production

The short winding cycle and high daily average production capacity make the winding machine a key equipment for motor manufacturers to improve production efficiency. Fault self-diagnosis and remote maintenance functions further reduce downtime and improve overall efficiency.

3. Comprehensive display of technical advantages

1. Improve product quality

Precision winding technology reduces the electromagnetic noise of the motor and improves the energy efficiency level. Reduce manual intervention and improve product consistency and defective rate control.

2. Reduce manufacturing costs

Automated production reduces labor costs and improves material utilization. Modular design facilitates maintenance and reduces long-term operating costs.

3. Adapt to industry trends

Compatible with the needs of miniaturized and high-performance motors in new energy vehicles, drones, home appliances and other fields. Support non-standard customization and quickly respond to customers’ development needs for special winding processes.

IV. Rich display of application scenarios and cases

1. New energy vehicle drive motor

The winding machine needs to adapt to high-speed and high-slot-fill-rate stators to ensure the power density of the motor. By optimizing the winding process and parameter settings, the performance and reliability of the motor are improved.

2. Drone motor

Requires lightweight design, and the winding machine needs to support ultra-fine wire diameters and micro stators. Through precision winding technology and optimized layout, the efficiency and stability of the motor are improved.

3. Home appliance motors

For example, air-conditioning compressor motors need to meet high temperature and high humidity environments. The winding machine ensures the safe and reliable operation of the motor by integrating online insulation detection functions.

4. Outlook on future development trends

As motors develop towards higher efficiency and miniaturization, winding machines will further integrate cutting-edge technologies such as AI visual inspection and digital twins. Through real-time monitoring and data analysis, accurate control and optimization of the winding process can be achieved. At the same time, modular and intelligent design concepts will make winding machines more flexible and efficient, and promote the upgrade of the motor manufacturing industry to “intelligent manufacturing”.

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]