The precision of the fully automatic stator winding machine is a key factor in ensuring the quality of the motor stator winding. It is affected by hardware configuration, control system, process parameters, environmental factors, maintenance management and other aspects. The following is a detailed analysis of these factors and reasonable configuration suggestions:

I. Key factors related to precision

I. Hardware configuration

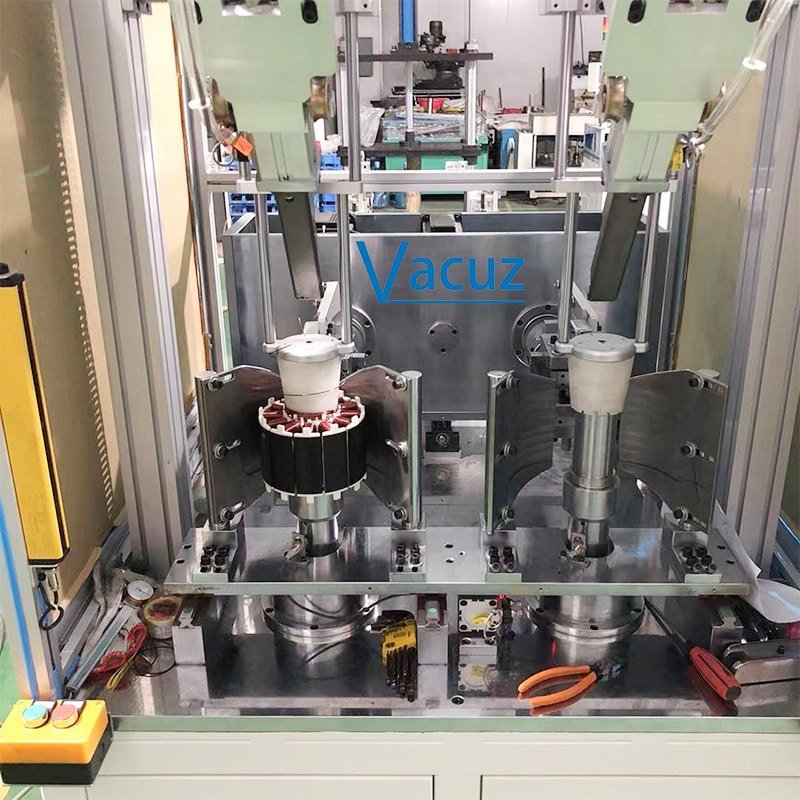

1. Winding mechanism: The winding head driven by a high-precision servo motor, combined with precision guide rails and ball screws, can ensure the accurate positioning of the winding action and reduce errors.

2. Tension control system: Equipped with a brand servo tensioner, the wire tension is adjusted in real time through closed-loop control to avoid uneven coil tightness caused by tension fluctuations, which affects the winding quality.

3. Molds and fixtures: The use of high-precision molds can prevent wire scratching, and the close cooperation of the fixture positioning device and the wire arrangement device can ensure the accurate guidance of the wire.

4. Wire arrangement device: It is mainly composed of a tensioner, a steel needle, etc. Reasonable setting of tension can ensure that the wires are arranged neatly and reduce crossing or overlapping phenomena.

2. Control system

1. PLC servo drive controller: As the “brain” of the winding machine, a high-precision controller must be selected to ensure that the winding steps are accurately executed according to the predetermined program and improve the winding accuracy.

2. Motion control algorithm: The use of advanced motion control algorithms can optimize the winding trajectory and speed, reduce inertia errors, and further improve the precision of the winding machine.

3. Process parameters

Winding speed: It needs to be reasonably set according to the wire diameter and stator specifications to avoid wire breakage or uneven winding due to excessive speed, which affects product quality.

Tension size: Too little tension will cause the coil to be loose, and too much tension may break the wire. It is necessary to find a suitable value through debugging to ensure the tightness and stability of the coil.

Number of turns and layers: Accurately controlling the number of turns and layers of the coil can ensure winding accuracy and meet the design requirements of the motor stator.

4. Environmental factors

Temperature and humidity: Changes in ambient temperature and humidity will affect the tension of the wire and the stability of the equipment, and need to be controlled to reduce the impact on winding accuracy.

Vibration and interference: Reducing external vibration and electromagnetic interference can ensure stable operation of the equipment and improve winding accuracy.

5. Maintenance and management

Regular maintenance: Regularly maintain and service the winding machine, check the wear of each component, and replace the wearing parts in time to extend the service life of the equipment and maintain winding accuracy.

Debugging and calibration: Before the winding machine is officially put into production, comprehensive debugging work is carried out to ensure that all parameters and device configurations are in good condition and improve the winding quality.

2. Reasonable configuration suggestions

1. Choose high-precision hardware

Give priority to key components such as high-precision servo motors, guide rails, ball screws, etc. from well-known brands to ensure the mechanical accuracy of the equipment.

Configure high-precision tensioners and molds to improve the tension and positioning accuracy during the winding process.

2. Optimize the control system

Use high-precision PLC servo drive controller, combined with advanced motion control algorithms, to achieve accurate control of the winding process.

Introduce programming control technology, preset winding programs, and reduce errors caused by human factors.

3. Finely set process parameters

According to the stator size and wire specifications, finely adjust the key parameters such as winding speed, tension, number of turns, etc.

Through experiments and debugging, find the right combination of parameters to ensure winding accuracy and stability.

4. Control environmental factors

Set a constant temperature and humidity environment around the winding machine to reduce the impact of temperature and humidity changes on the equipment.

Take vibration reduction measures, such as installing shock-absorbing pads, to reduce the impact of external vibration on the equipment.

5. Strengthen maintenance and management

Develop a detailed maintenance plan and regularly maintain and service the winding machine.

Strengthen the training of operators, improve their operating skills and maintenance awareness, and ensure stable operation of the equipment and winding quality.

In summary, by rationally configuring the hardware configuration of the fully automatic stator winding machine, optimizing the control system, finely setting process parameters, controlling environmental factors, and strengthening maintenance and management, the precision and stability of the winding machine can be significantly improved, providing a strong guarantee for the high-quality production of motor stators.

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]