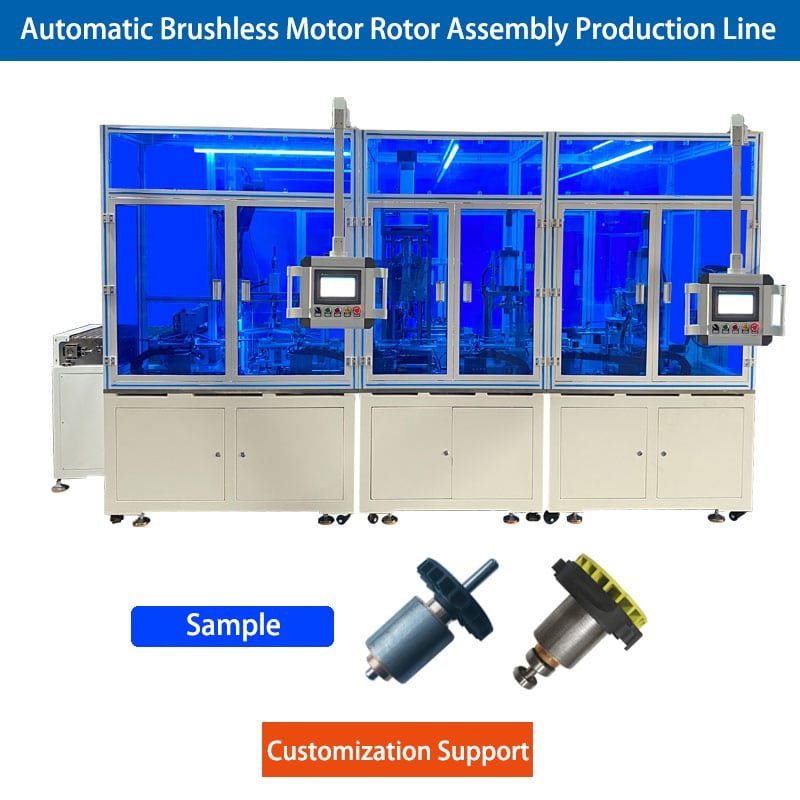

Brushless DC motor assembly is more complex, there are several processes, need to be completed step by step, each step must be rigorous, before the main use of manual assembly mode, less efficient; and now are basically using the production line intelligent mode, assembly efficiency increased significantly, then the brushless DC motor assembly line what are the main production processes? Let’s take a look at the specific process with Vacuz!

1. rotor part mainly includes: rotor core riveting shaft, rotor core external turning, core outer diameter measurement, press-fit copper sleeve, O-ring installation, gasket installation.

2. Stator part mainly includes: cutting short circuit ring, assembling short circuit ring, welding short circuit ring, slot paper, installing insulation frame, winding stator, perforating lead wire.

3. End cover part mainly includes: end cover punching, tapping, end cover oiling, (bearing, sealing ring, bearing sleeve) assembly, bearing press fitting.

4. Motor assembly part mainly includes: rotor assembly, stator assembly, rear end cap assembly, tightening, bearing calibration, coupling installation, motor testing, labeling.

The above is part of the process of one of the full line of brushless motor equipment, can provide non-standard customized equipment according to customer processes, equipment equipped with testing equipment to ensure product quality.

Brushless DC motor assembly line is equipped with intelligent central control system, which can easily realize work order switching, one-key line change, intelligent error prevention and real-time monitoring, and can be seamlessly connected with MES system to easily realize fast production and production management.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]