As an indispensable part of the motor structure, the stator and its various parameters play a decisive role in the overall performance and quality of the motor. These parameters further affect the configuration selection of the winding machine when winding the coil. The following is Vacuz’s in-depth analysis of the relationship between the two, as well as some suggestions on how to reasonably match the equipment:

1. How stator parameters affect the winding machine configuration:

1. Stator slot orientation:

Stators with slots facing outward are commonly found in brushless motors such as model airplanes, drones and fascia guns. The winding process of this type of stator is relatively intuitive, so conventional winding machines can be used for operation.

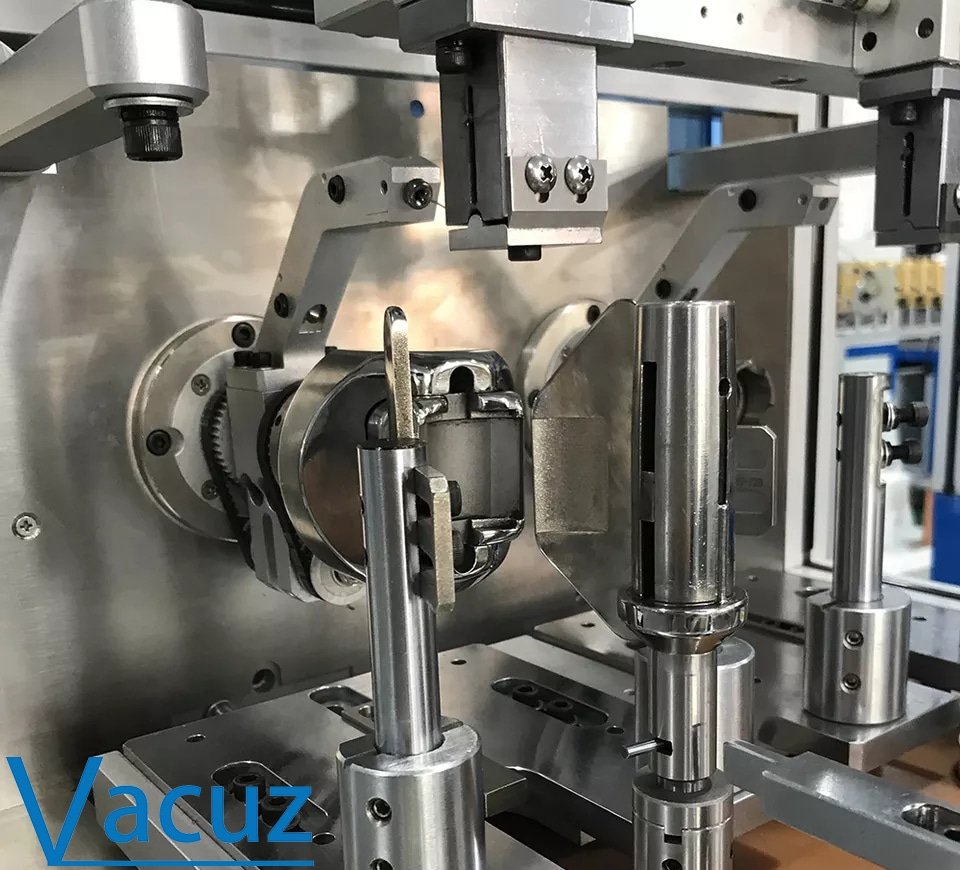

For stators with slots facing inward, such as motor stators in household appliances, water pumps and power tools, the winding requirements are more stringent, and high-precision winding machines are often required to meet production needs.

2. Inner and outer diameter dimensions of the stator:

Accurate measurement of the inner and outer diameters of the stator is crucial for the selection of the winding machine. If there is a deviation in the measurement data, it may lead to the selection of mismatched winding molds, which in turn affects the winding quality of the coil.

In addition, the size of the stator outer diameter will also affect the number of stations and the axis spacing of the winding machine, which will further affect the production efficiency.

3. Stator stacking thickness (i.e. height):

The stator stacking thickness determines whether the winding machine can handle the stator of this height, and also affects the winding speed.

For stators with larger stacking thickness, it is recommended to choose a winding machine manufacturer with stronger technical strength to ensure the stability and durability of the equipment.

4. Wire diameter size:

Wire diameter is a key factor affecting the selection of winding machines. Generally speaking, ordinary fully automatic winding machines are suitable for wire diameters ranging from 0.1 to 1.3 mm.

If the wire diameter is less than 0.1 mm or greater than 1.3 mm, a specially designed winding machine must be selected to avoid damage to the wire or poor winding quality.

5. Number of turns (i.e. the number of turns of the coil):

The number of turns determines the number of coils that the winding machine needs to wind, which affects the time required for winding.

The more turns, the longer the winding time, and the higher the requirements for the stability and efficiency of the winding machine.

6. Number of slots and slot pitch:

The number of slots determines the winding speed and difficulty of the winding machine. The more slots, the slower the winding speed.

At the same time, the slot pitch will also affect the difficulty of winding. The smaller the slot pitch, the more complicated the winding process.

2. Strategy for reasonable matching of equipment

1. Select the winding machine according to the stator type:

For stators with slots facing outward, ordinary flying fork winding machines can be selected and matched with stepper motor drive.

For stators with slots facing inward or requiring precise wiring, it is recommended to choose a winding machine driven by a servo motor.

2. Adjust the winding machine configuration according to stator parameters:

Select the appropriate winding mold and number of workstations according to the inner and outer diameters, stack thickness and other parameters of the stator.

Select the appropriate wire processing method and tension control device according to the size of the wire diameter.

Adjust the winding speed and procedure according to the number of turns and slots.

3. Choose a winding machine manufacturer with strong technical strength:

Choose winding machine manufacturers with rich experience and deep technical accumulation to ensure the quality and performance of the equipment.

Give priority to manufacturers that can provide non-standard customized designs to meet the needs of special stator parameters.

In general, there is a close connection between the configuration of the fully automatic motor stator winding machine and the stator parameters. When choosing a winding machine, it is necessary to fully understand the various parameters of the stator and reasonably adjust the configuration of the winding machine according to these parameters to ensure the quality and production efficiency of the winding. At the same time, choosing a winding machine manufacturer with strong technical strength is also an important guarantee to ensure the quality and performance of the equipment.

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]