Multi-functional winding machine application performance is high, a wide range, the use of electric coil industry will be more, in the face of this rapidly developing society, these mechanical advantages highlighted more obvious, the times are different, naturally in the do-it-yourself device to improve, speed up the efficiency of work, which is on the electric coil side, or a certain advantage of ah!

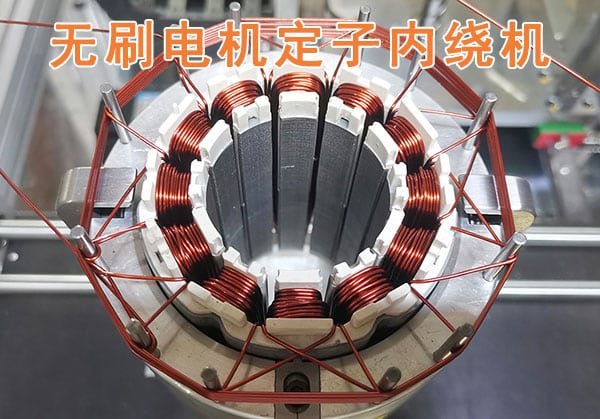

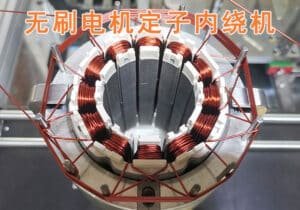

Currently common winding machine mainly and single-head winding processing is the main function is also relatively single, multi-head linkage winding will greatly improve the efficiency and output of the winding machine, the design can effectively reduce the complexity of the equipment, improve the driving efficiency, facilitate the process of adjustment, reduce maintenance. At present, the processing of electromagnetic coils, motor coils and ballast coils have used multi-head linkage technology; the winding machine is a step in coil processing, and future development will certainly enable the integration of multiple functions to achieve fully automated coil processing, testing, and completion of multiple auxiliary processes.

The modular function controller can be flexibly configured according to the different functional requirements of the winding machine. Relative to the motor winding industry, the series-excited motor rotor flying fork winding machine, PLC has the advantages of strong computing power, easy communication, lower cost, winding machine control requirements are relatively simple and fixed, ideal for the application of modular combination controller; relative to the electronic transformer industry skeleton winding, induction motor core winding, high precision voice coil and hollow coil winding applications, since 2003 Domestic application in the winding industry can be said to have a typical representative of the high-speed motion controller manufacturers, with more flexible than PLC Basic programming language environment, code running and calculation speed capabilities, communication CAN port makes the rich IO and expansion of the number of axes to be extended, the same kind of high cost performance characteristics, winding machine control requirements are relatively complex and flexible and variable hardware configuration port programming, very suitable for Diversified application of modular combination of controllers. At present, the winding machine is more often used in the PLC and has the winding industry representative of the DTG series high-speed multi-axis motion controller.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]