Vacuz machinery and equipment gives you a general idea about the height of the winding object and the arranger!

The winding technique of the winding machine is very important. First of all, the characteristics of the “line”, the number of cycles and the appearance of the material, the speed of the lift should be like sticky silk, colored cotton thread, etc., and a group of the diameter of the line should be increased a lot because the skin is not smooth, no inertia characteristics. Filament winding should not be too slow, but should begin with a slow climb, so as not to break the wire. Coarse wire should not be too fast (overspeed), but pay attention to the adequacy of low and medium-speed torque.

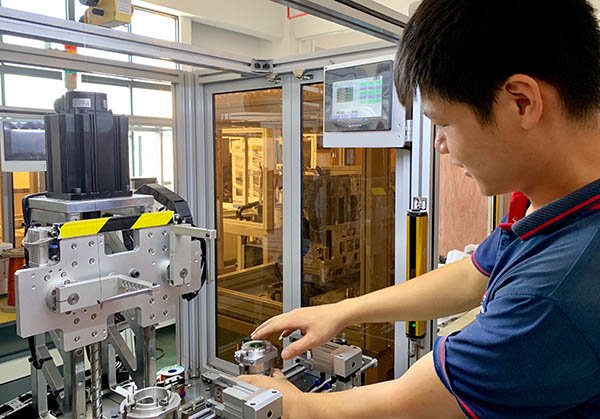

When the automatic wire winding machine manufacturer talks about the use of aluminum wire, please note that the pulling force should be adjusted to be much smaller than that of copper wire of the same thickness, so as not to pull the wire too large in diameter, the outer insulating coating bursting and affecting the quality of the product. When using aluminum wire, due to the reduced expansion force, the wire diameter should be increased appropriately. The combination of its own power requires the ability to go less and move more. The shape of the winding object of the transformer winding machine depends largely on the height of the setting machine and the distance off the machine. Square winding objects should not be too fast, the center will be rounded and uneven, affecting the neatness of the line.

The height of the object to be wound and the wire should be appropriate, too low the wire will easily fall into the next layer, too high there will be skipping. The distance between the wire and the object to be wound should not be too far, which will affect the precision of wire coupling. The tension of the arrangement device is also related to the beauty of the winding arrangement. The width of the winding material and the calibration of the starting point are of the utmost importance. When the start point is correct, start winding and you can stop at both ends to test that the width is set correctly.

When starting the winding, whether aesthetically pleasing or not, the starting winding point is too far forward or too far back (no perpendicularity between the wire outlet and the object to be wound). Too fine or too dense (incorrect wire diameter setting). The ends rotate too fast or too slow (incorrect width setting: too fast = not wide enough, too slow = too wide). Whether the connection becomes faster and slower (fine-tune the wire diameter again: faster = smaller, slower = larger).

Note the coupling of the layers of wire behind the windings. The shape of the object changes through multiple layers of entanglement. The wire diameter labeled for the enameled wire is the actual wire diameter, so the wire diameter must match the thickness of the enamel. The reset (displacement) of the wire liner after the winding is complete is also important. For thin windings, start the winding point forward and widen to a narrower point. Straddle winding, which generally overcomes the setup pattern.

왓츠앱/위챗: +86 13075286997

이메일: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="작은 가시성,중간 가시성,큰 가시성" class="" id=""][/fusion_form]