Automatic winding and tying machine common fault classification: electrical, mechanical, transmission, pneumatic ……, where the electrical part is divided into strong, weak electricity, and winding and tying machine manufacturers usually in the design, application and maintenance of its CNC system, there are considered to be vulnerable parts, easy to common fault location with abnormal alarms, alarm circuit operation, not only in the display or operation control panel to provide sound, light and other alarm data, but also transmits protective instructions. Not only in the display or operation control panel to provide sound, light and other alarm data, but also transmits protective instructions. Make the operating system power outage or stop working to ensure safety and prevent the expansion of common failures.

Winding and tying machine maintenance methods

(1) spare parts replacement method, in the maintenance of the winding machine, replace the components suspected of common failures with complete parts, maintenance personnel basically determine the cause of common failures, you can use this way to quickly diagnose common fault areas, and make the winding machine quickly put into normal operation, followed by bad components back to repair, which is currently more commonly used troubleshooting methods.

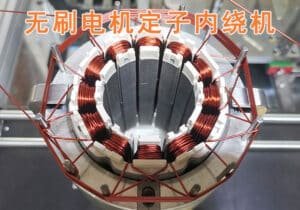

BLDC Motor Winding

(2) the whole machine calibration method, usually the case of winding machine because of instantaneous common faults caused by the whole machine is incorrect, you can use the hardware configuration calibration or switch operating system power supply successively to eliminate common faults, if the operating system operation storage area because of voltage instability, unplugging pcb circuit board or rectifier switch power supply undervoltage protection leads to confusion, it is necessary to initialize the system to eliminate, before eliminating to pay attention to do a good job of the current backup Data records, if the calibration of the initialization of common faults still can not be eliminated, then the hardware configuration replacement diagnosis.

(3) the preparation of trial run program method, the preparation of a scientific and reasonable application and successful operation is to confirm the integrity of the entire system function or not according to the main parameters of some winding line is not set correctly may lead to common failures of the operating system or a function is invalid, sometimes because the user program is incorrectly caused by common failures downtime, for this reason can be used to prepare a trial run application to check and correct the user program incorrectly to guarantee its normal operation.

"WhatsApp" / "Wechat": +86 13075286997

El. paštas: sales@vacuz.com