The rotor winding machine and the stator winding machine are two common winding machine equipment, which are mainly used to wind the rotor and stator coils. So what are the similarities and differences between the rotor winding machine and the stator winding machine? How to choose the equipment reasonably? Vacuz will analyze it for you!

Vidinė BLDC variklio statoriaus ritė

1. Similarities:

1. Core functions and technical indicators: Both are used for coil winding in motor manufacturing, with strict requirements on winding accuracy, tension control, and wire arrangement uniformity, and need to adapt to different wire diameters and insulation materials.

2. Automation and quality control: Modern equipment is generally equipped with automation functions, such as tension control and automatic wire arrangement, and needs to avoid winding defects and be equipped with online detection functions.

2. Differences:

1. Winding objects and methods: The rotor winding machine is mainly aimed at cylindrical rotor cores, using oblique winding, concentrated winding and other methods; while the stator winding machine is aimed at annular slot stator cores, using needle type, chain winding and other methods.

2. Process difficulties and equipment structure: Rotor winding needs to solve the centrifugal force problem, while stator winding needs to face the challenges of complex slot shape and high-precision wire arrangement. In terms of equipment structure, the two are also different to adapt to different winding needs.

III. Reasonable selection suggestions:

1. According to the motor type: Select equipment with corresponding winding capabilities and technical parameters.

2. According to the production scale: For small batches and multiple varieties, modular and fast-changing equipment is selected; for large-scale production, fully automated production lines are given priority.

3. According to technical parameters: Such as winding accuracy, efficiency indicators, etc., need to match the subsequent process.

4. According to budget and after-sales service: Pay attention to cost-effectiveness and service capabilities, and choose suppliers that provide process support and quick response.

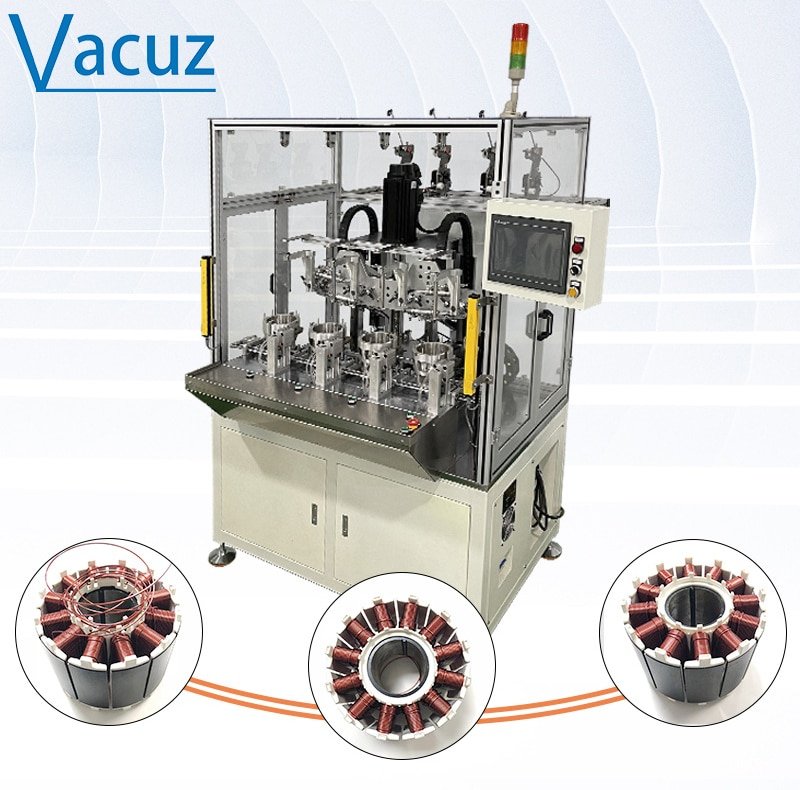

Automatinis bešepetėlinis vidinis statoriaus ritės servo variklio tipo adatos vyniojimo aparatas

What are the similarities and differences between rotor winding machines and stator winding machines? How to choose reasonably? Vacuz has made a simple explanation, I hope it can help you!

El. paštas: sales@vacuz.com