Production life, everywhere need to use a variety of motors, from small to electric toothbrushes, drones aerial models, handheld fans, hair dryers, power tools, large to pumps, stepper servo motors, etc., so how do you Doozhi motor production? What equipment needs to be used?

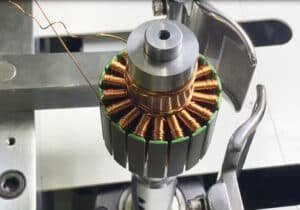

BLDC ritės vyniojimas

In fact, at present, there are fully automatic motor production lines, there are also sections of the assembly, it mainly depends on the size of the manufacturer and funds, because the custom motor production line is not cheap

Conventionally speaking, the production of motors mainly requires the following equipment.

1. rotor production line assembly, core machine, winding machine, spot welding machine, dispensing machine, baking machine, fan blade machine, balancing machine, precision turning machine, test system, meson machine, rotor under the machine, etc..

2. Large shell assembly part, large shell feeding machine, stone magnet machine, dispensing machine, baking machine, bearing machine, etc.

3. small shell assembly part, feeding and positioning of small shells, bearing assembly, carbon crystal into brush holder, brush insertion, rivet pressing, etc.

4. motor assembly, assembly of rotor, large and small shells; then assembly of motor accessories.

5. motor accessories assembly, such as gearbox, worm gear, magnetic guard ring and other accessories assembly.

Ritės vyniojimas

Vacuz motor equipment, which can be specially customized for motor production lines, has complete motor production lines for assembly as well as partial automatic production lines for rotors, end caps and housings. Our products are widely used in the fields of auto parts, home appliances, power tools, medical and electric toys, etc.

"WhatsApp" / "Wechat": +86 13075286997

El. paštas: sales@vacuz.com