What can be done to improve the stability of automatic winding machines?

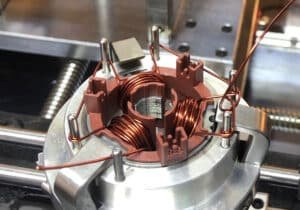

For example: various motors, fluorescent lamp ballasts, transformers of various sizes, TV sets. Radio, inductor coils, line output transformers (high voltage packages), electronic igniters, high voltage coils on mosquito extinguishers, speakers, earphones, microphone voice coils, various soldered center-of-perimeter machines, etc. cannot be exemplified. Coils need to be wound with a winding machine. In the textile industry, cotton yarns, man-made fiber yarns, etc. are used to wind various yarns and yarns suitable for textile machines. These need to be wound by a winding machine. The same batch and the same type of winding machine will have different performance in different customer companies. The winding machine and other equipment can perform at a Z-max level and vice versa, and it can easily cause an incredible variety of stable symptoms.

Automatic winding machines

Spoles uztīšana

The ambient temperature is not appropriate for the plant. Too low or too high temperatures are killers for all electronics. This should be a consensus, so Z is good to have auxiliary temperature regulation equipment in the installation shop of the winding machine. If environment is involved, then a good factory environment includes temperature, temperature, floor, air, power, space, operator, etc. The ambient humidity is not suitable. Wirewound machines consist of many integrated circuits of electronic components, and their insulation performance is highly dependent on the ambient humidity. If the humidity is too high, it can easily lead to short circuit and burned circuit board. If the humidity is too low, it is easy to generate static electricity and can penetrate certain electronic components. Therefore, if the humidity is too high or too low, it can pose a potential threat to the winding machine. If the power supply system is unstable, the power supply voltage fluctuates greatly and is prone to power failure. Industry and life are developing rapidly and the demand for electricity is increasing. In many areas, the power supply is insufficient and the voltage is unstable and prone to power failure. Something has happened. The voltage is unstable and the power supply suddenly shuts off, causing frequent system restarts. Electronic components may be damaged due to the current. Therefore, the stability of the working environment power supply is related to whether the winding machine works properly.

It can be protected by voltage regulator and UPS uninterruptible power supply. The choice of specific equipment depends on the load power and the required operating time. The ground is alarming. In many factories, the motor needs to generate physical displacement actions such as displacements and vibrations, which not only make a lot of noise, but also the violent vibrations caused by the work of the machine can damage the winder. A sponge is placed under the body of the winder to cushion the object to reduce the risk of vibration. In addition, the problem of static protection requires us to have a good instrument grounding on the winder. Then use 40X40X4 galvanized flat steel and the grounding body for reliable welding (each weld must be carefully rust-proofed) and then connect to the building in order to replace the 25mm copper cable with the system grounding terminal and the winder grounding point. This will effectively reduce the hazards caused by static electricity.

WhatsApp/Wechat: +86 13075286997

E-pasts: sales@vacuz.com