As a key equipment in the motor manufacturing process, the brushless motor stator winding machine directly affects the quality and production efficiency of the motor. In order to meet the market’s demand for high-performance and high-efficiency motors, it is particularly important to develop and design an excellent brushless motor stator winding machine. Vacuz will comprehensively analyze the key points of the R&D and design of brushless motor stator winding machine from three aspects: R&D design requirements, humanized design requirements and design considerations for stator characteristics.

2. R&D and design requirements

1. High-performance controller

Integrated Advanced PLC/IPC: Adopt programmable logic controller (PLC) or industrial personal computer (IPC), combined with high-speed data processing chips, to improve the system’s real-time response and computing capabilities.

Independently developed special controllers: Develop special controllers for specific winding process needs to ensure the stability and reliability of the equipment.

2. Intelligent algorithm

Special software development: Integrate machine learning algorithms, develop special software, and optimize winding parameters through historical data analysis.

Model prediction and real-time adjustment: Create a model to predict winding effect, adjust winding parameters in real time, and improve accuracy and efficiency.

3. High accuracy sensor

Select high-precision sensors: such as tension sensors, photoelectric encoders, linear displacement sensors, etc. to ensure accurate capture of various parameters during winding.

4. Intelligent detection technology

Machine Vision System: Introduce machine vision system, combined with AI image recognition technology, to realize automatic detection of winding quality.

Laser sensor measurement: Use laser sensors to perform high-precision dimension measurements to improve detection accuracy and efficiency.

5. Highly automated

Full automatic winding system: Develop a fully automatic winding system, integrating automatic loading and unloading, automatic wire change, automatic detection and other functions.

Industrial Robot Technology Application: Adopt industrial robot technology to improve automation level and production efficiency.

6. Modular design

Modular mechanical structure and electrical system: Design modular mechanical structure and electrical system to facilitate independent upgrade or replacement of different functional modules.

Quickly adjust equipment configuration: Quickly adjust equipment configuration according to the needs of different stator products to improve the versatility and flexibility of equipment.

7. Hardware components and manufacturing processes

Select high-performance components: Select high-performance servo motors, drivers, screws, guide rails and other components from internationally renowned brands to ensure the stability and durability of the equipment.

Implement ISO quality management system: Every link from raw material procurement to production and processing meets high standards and ensures product quality.

3. Humanized design requirements

1. Operation interface

Intuitive Graphic Interface: Adopt an intuitive graphical interface design, combined with icons and text descriptions to reduce operation difficulty.

Operation Guide and Video Tutorial: Provides detailed operation guide and video tutorials to help operators get started quickly.

2. Interaction method

Voice Interaction Function: In addition to the touch screen, voice interaction function is added, and voice command input and feedback are supported.

Personalized Setting Options: Provide personalized operation interface setting options for different operators to meet the needs of different users.

3. Easy to maintain

Easy to disassemble and assemble: Design a mechanical structure that is easy to disassemble and assemble for easy maintenance and maintenance.

Maintenance Manual and Repair Video: Provides detailed maintenance manuals and repair video tutorials to help users quickly solve common problems.

4. After-sales service

Professional after-sales service team: Establish a professional after-sales service team, providing 24-hour online technical support and remote fault diagnosis services.

Regular training and technical consultation: Provide users with regular training and technical consultation services to improve users’ user experience and satisfaction.

4. Design considerations for stator characteristics

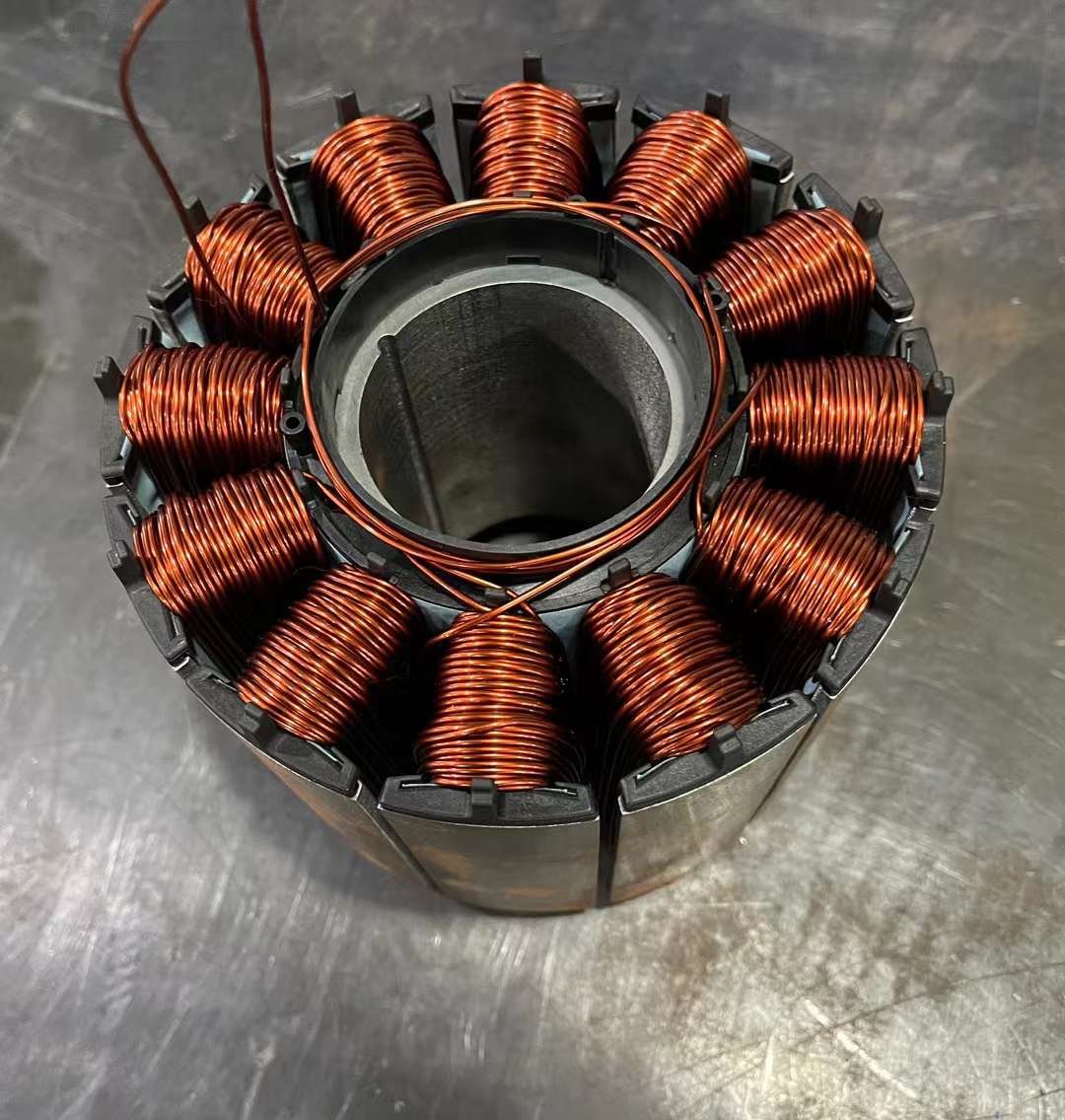

1. Stator outer diameter and inner diameter

Select the appropriate winding machine model: According to the size range of the stator outer diameter and inner diameter, select the appropriate winding machine model and number of workstations to ensure winding quality and efficiency.

2. Stator stack thickness

Avoid scraping and other problems: Consider the impact of the stator height on the swing needle method and the way of passing the thread to avoid scraping, damaged lines, and disconnection problems, and improve the quality of the winding.

3. Enameled wire diameter

Select the appropriate winding machine configuration: Select the appropriate winding machine configuration according to the wire diameter, such as a high-speed winding machine or tension control system, to ensure the stability and accuracy of the winding process.

4. Number of coil turns and slots

Adjust winding speed and accuracy: Adjust the winding speed and accuracy of the winding machine according to the requirements of the number of coil turns and the number of stator slots to meet the needs of different stator products.

5. Notch direction

Select the appropriate winding machine type: Select the appropriate winding machine type according to the notch direction, such as an inner winding machine or an outer winding machine, to ensure the smooth progress of the winding process.

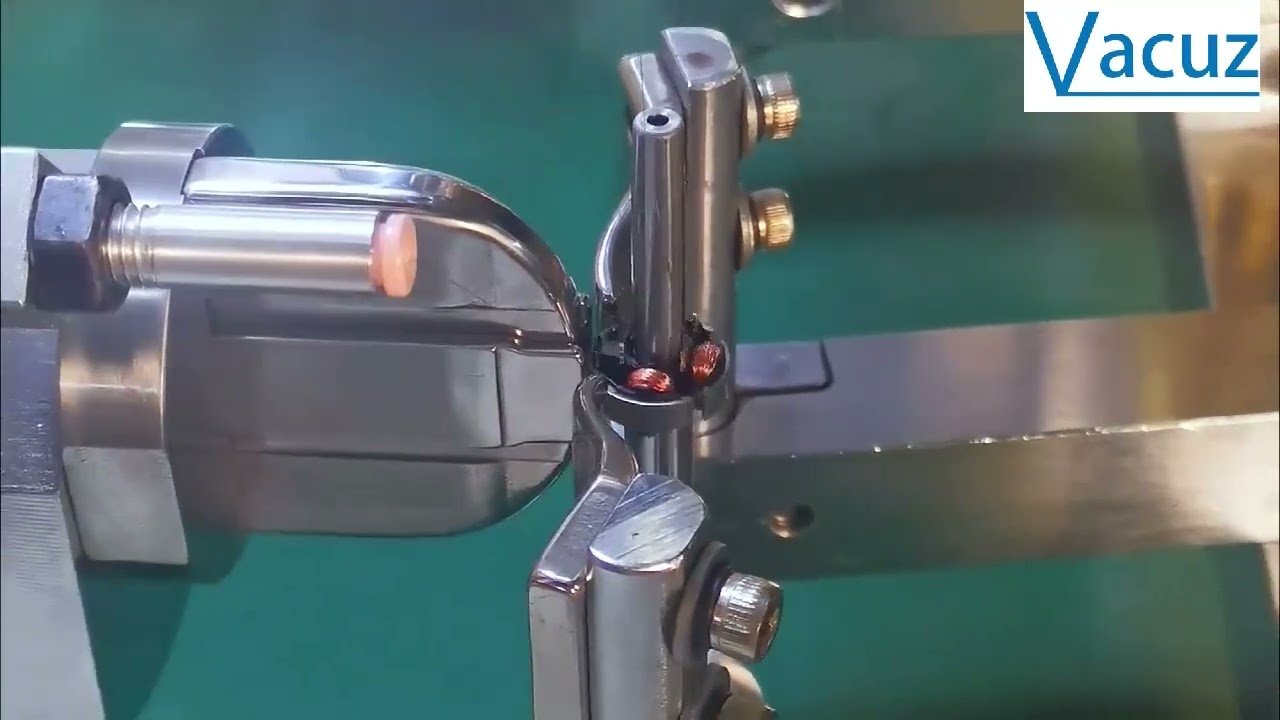

Vacuz Double Stations Automatic BLDC Brushless Drone Motor Stator Coil Flying Fork Winding Machine And Paper Insertion Machine Packing

The R&D and design requirements of brushless motor stator winding machines cover multiple aspects, including high-performance controllers, intelligent algorithms, high-precision sensors, intelligent detection technology, high automation, modular design, hardware components and manufacturing processes, etc. At the same time, in order to meet humanized needs, we also need to pay attention to the design of operation interface, interaction methods, ease of maintenance and after-sales service. In addition, special design considerations for the characteristics of the stator are also key to ensuring the performance of the winder. By taking these aspects into consideration, a brushless motor stator winding machine that is high-performance, efficient, easy to use and durable can be created to meet the needs of the market.

E-pasts: sales@vacuz.com