Brushless motor winding machine automatic operation needs to set the corresponding program code, so there will be certain requirements for the operation of the design, at present, the brushless motor winding machine spindle motor, mainly including AC motors, DC motors and servo-driven motors, the use of speed regulators, there are some differences in the form of various motors, how the specific situation? Let’s take a look together!

Spolevikling

1. Speed control mode of AC motor winding machine

This type of motor does not have speed control function, therefore, if you want to adjust the speed, you also need to install electromagnetic control equipment or drivers to achieve, the use of inverter motor to achieve the effect of speed regulation, can be considered a relatively energy-saving way.

2.DC motor speed control mode

This speed control mode needs to convert DC power supply, and the DC motor will be driven by brushless DC speed control board or motor driver.

3. Speed control mode of servo-driven motor

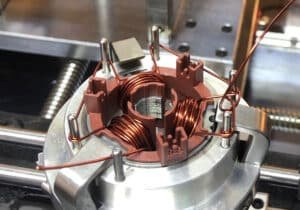

Stator winding machine is very precise equipment, which needs special drive device for control. The biggest feature of this drive device is its relatively stable torque, which can meet the needs of precision coil processing during operation.

The difference between ordinary winding machines and non-standard winding machines is that non-standard machines are generally equipped with the appropriate motor to achieve the desired effect according to the customer’s needs.

WhatsApp/Wechat: +86 13075286997

E-post: sales@vacuz.com