In the field of motor manufacturing, the choice of stator winding machines is crucial, which is directly related to production efficiency and product quality. But many friends don’t know much about the knowledge of wire winding machines, so it’s a bit difficult to choose. Vacuz will introduce it to you, hoping it can help you!

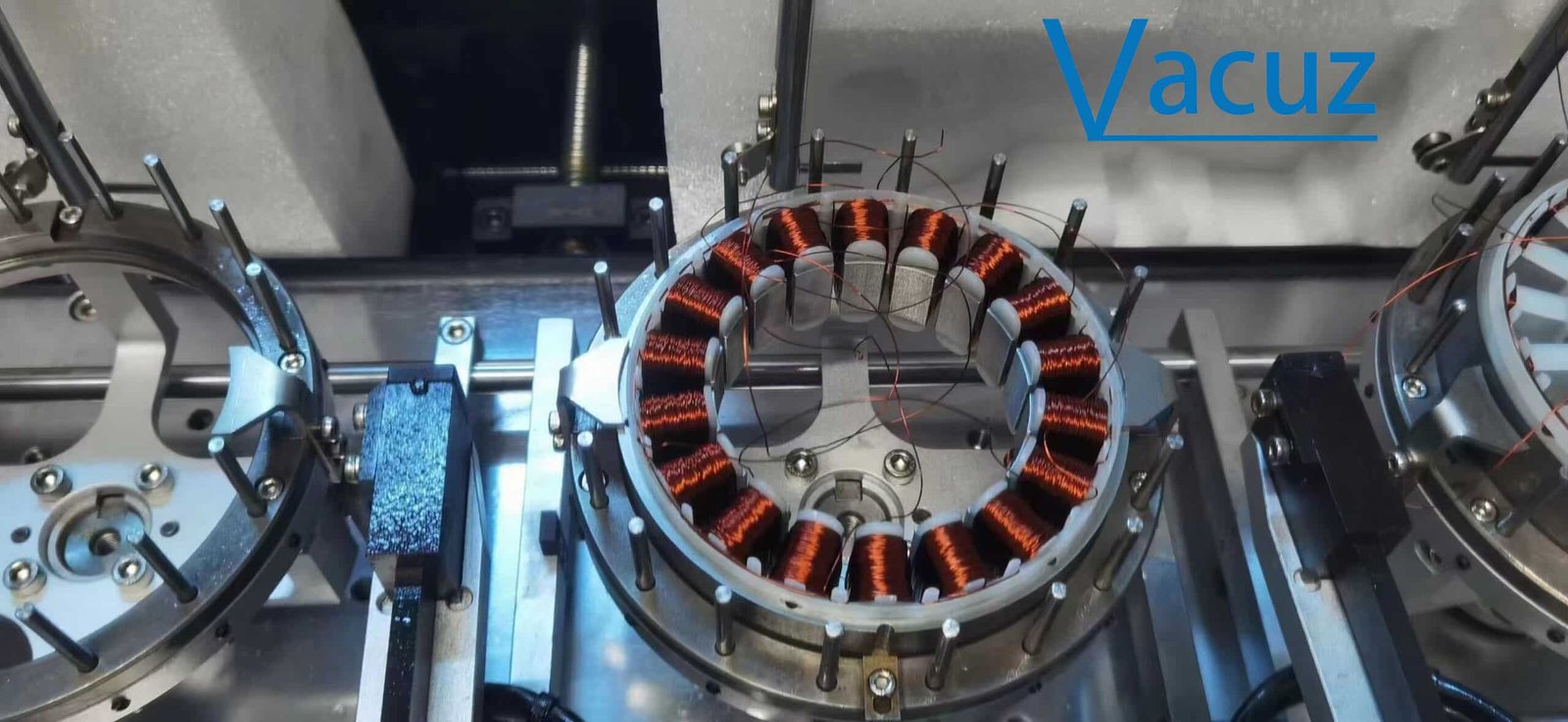

Vacuz 4&6 Stations Electric Toothbrush Motor Automatic BLDC Brushless Inner Hair Dryer Stator Coil Needle Winding Machine Equipment Price

1. Clarify the needs

Clarifying your production needs is the first step in purchasing. From motor type to stator specifications, to production scale and process requirements, each item needs to be carefully considered. Brushless motor or brushed motor, stator size, number of slots, wire diameter and other parameters. Small-scale production or large-scale manufacturing? What are the process standards such as winding accuracy, speed, and tension control? The answers to these questions will point your device choices to the direction.

2. Wire winding machine type

Choose the appropriate type of winding machine according to production needs. Manual winding machine, with its flexibility and low price, is suitable for small batch production or experimental proofing. Semi-automatic winding machines show high cost-effectiveness and wide applicability in medium-scale production. The fully automatic winding machine has become a good assistant for large-scale production with its high efficiency and high accuracy, although the equipment and maintenance costs are relatively high.

3. Equipment performance

Equipment performance is a core consideration in the purchasing process. The winding accuracy and speed are directly related to production efficiency and product quality. Stability and reliability determine the downtime and operating efficiency of the equipment. In addition, compatibility and scalability cannot be ignored, and they ensure that the device can adapt to changes in future production needs and support upgrades and expansions.

4. Manufacturer selection, quality assurance

Choosing a manufacturer with complete qualifications and rich experience is the key to ensuring equipment quality and after-sales service. On-site inspection of the manufacturer’s production environment, observe the equipment operation status, and test the equipment performance are effective ways to understand the manufacturer’s strength. At the same time, understanding the manufacturer’s after-sales service policies, including technical support, maintenance response time, spare parts supply, etc., is also an important part to ensure the stable operation of the equipment.

5. Price and cost-effectiveness, rationally weigh

In terms of price, it is necessary to avoid blindly pursuing low prices and sacrificing equipment quality. Comparing the quotations from multiple manufacturers, combining equipment performance and after-sales service, rationally weighing prices and cost-effectiveness. In addition, the long-term use cost of the equipment needs to be considered, including energy consumption, maintenance costs, etc.

VI. Other precautions

In addition to the above points, the following points should also be noted: select a manufacturer that can provide customized solutions and technical support; require the manufacturer to provide trial production services to ensure that the equipment performance meets production needs; refer to the evaluation and suggestions of other users, and choose a good reputation. manufacturer.

3 sets van servo dragende schacht machine + 2 sets van servomotor drone stator spoel wikkelen machine verzending

To sum up, when choosing a motor stator winding machine manufacturer and equipment, it is necessary to consider comprehensively from the aspects of production requirements, equipment type, performance, manufacturer qualifications, price and after-sales service. Through field inspections, trial production testing and multi-party comparison, selecting suitable equipment will lay a solid foundation for your production journey.

E-mail: sales@vacuz.com