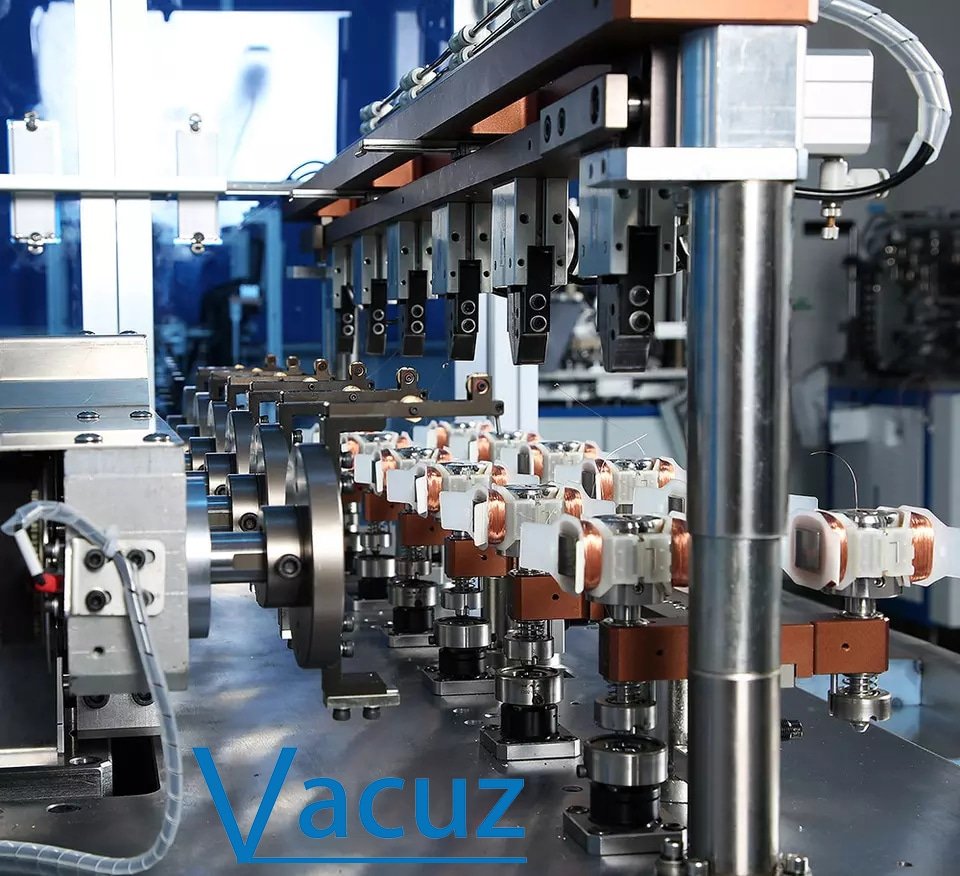

A comprehensive and in-depth analysis is needed for the various challenges and problems encountered by brushless motor stator winding machines during the winding process. For example, common problems such as chaotic wiring, damaged wires, insufficient winding accuracy, and poor equipment stability are directly related to production efficiency and product quality. Vacuz further refines and supplements some solutions, hoping to help everyone!

Dubbele Stations koelventilator motor spoel automatische BLDC Brushless Drone buitenste stator vliegende vork winden machine apparatuur te koop

1. In-depth analysis of winding problems

1. Chaotic wiring

Intelligent adjustment: Introduce intelligent algorithms to automatically adjust the wiring strategy according to parameters such as wire diameter and number of turns to reduce human errors.

Visual assistance system: Use machine vision technology to monitor the wiring status in real time, and immediately alarm and automatically adjust once confusion is found.

2. Damaged wires and broken wires

Material optimization: Use higher quality enameled wires to enhance their wear resistance and tensile strength.

Dynamic tension control: Develop a more sophisticated tension control system to adjust the tension in real time according to the winding speed and wire characteristics.

3. Insufficient winding accuracy

Laser positioning technology: Laser positioning is used to ensure accurate positioning of the mold and stator frame, and improve winding accuracy.

High-precision sensor: Integrate high-precision sensors to monitor the position and size changes during the winding process in real time to ensure that the accuracy meets the standard.

4. Poor equipment stability

Redundant design: Redundant design is adopted on key components. Once a component fails, the spare component is immediately started to ensure production continuity.

Remote monitoring and diagnosis: Establish a remote monitoring system to collect equipment operation data in real time, predict potential faults through big data analysis, and perform fault diagnosis and repair remotely.

2. Comprehensive solution recommendations

1. Intelligent upgrade: Promote the development of equipment in the direction of intelligence, integrate AI algorithms, machine vision, high-precision sensors and other technologies, and realize the automation, intelligent monitoring and adjustment of the winding process.

2. Modular design: The modular design concept is adopted to facilitate the rapid maintenance and upgrade of equipment, reduce maintenance costs, and improve equipment flexibility.

3. Training and education: Strengthen the training and education of operators, improve their equipment operation skills and maintenance awareness, and ensure the stable operation of the equipment.

4. Continuous improvement and feedback: Establish a continuous improvement mechanism, encourage operators and equipment suppliers to put forward improvement suggestions, and continuously optimize equipment performance and production processes.

Hoge snelheid vier assen koeling ventilator motor automatische BLDC Brushless binnenste Stator spoel naald wikkelen machine

What are the common winding problems of brushless motor stator winding machines? How to solve these problems? Vacuz has made a brief description above, and I hope these little knowledge can help everyone!

E-mail: sales@vacuz.com