In the manufacturing process of brushless motors, stator winding technology is very important and plays a crucial role. Below, Vacuz will conduct an in-depth analysis of several mainstream winding methods and the working principles behind them, hoping to help everyone!

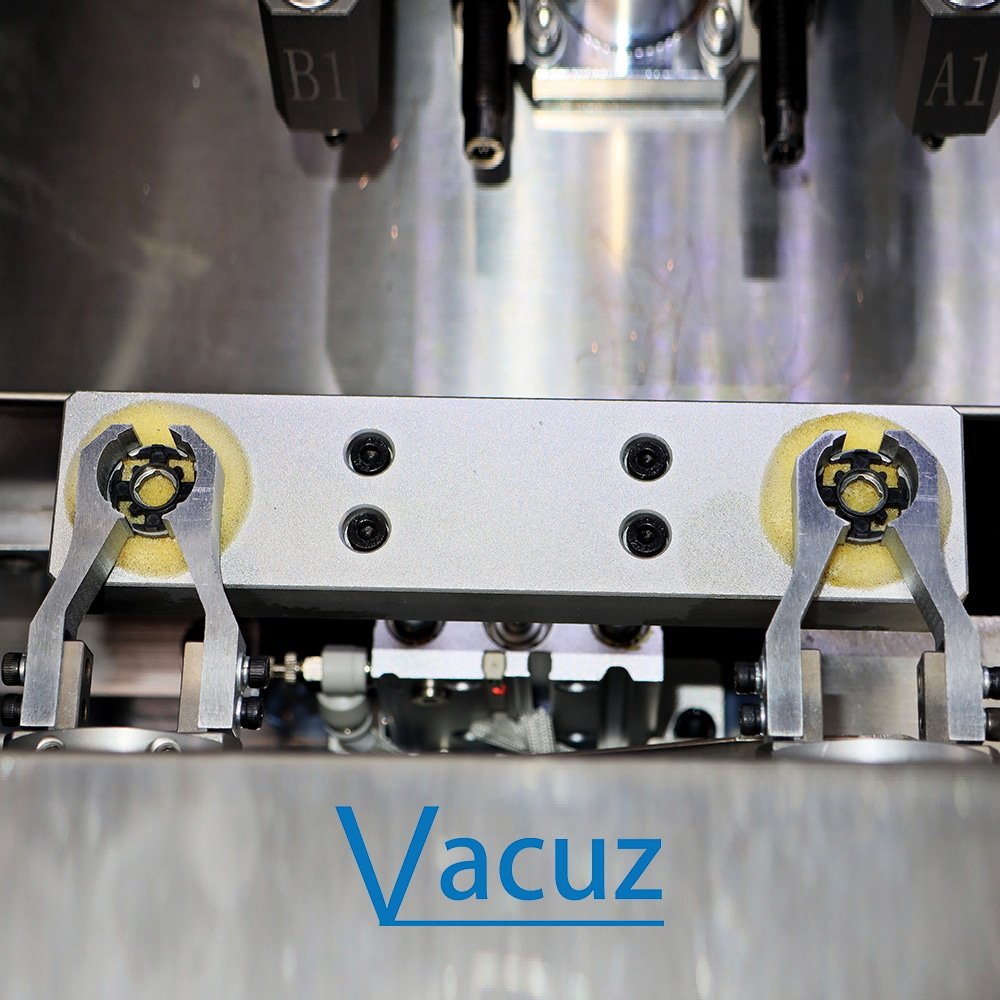

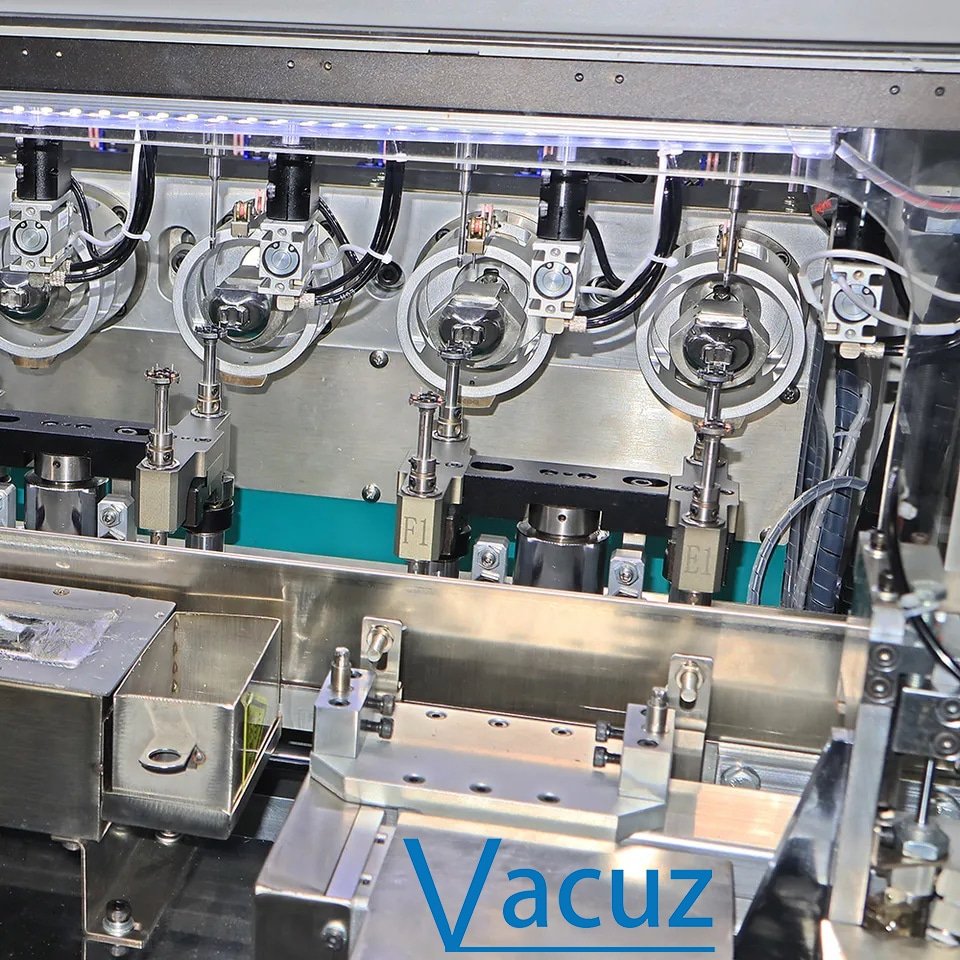

Buitenste Stator Trillen Plaat Voeden Vacuz volledig automatische BLDC Brushless Drone UAV koelventilator motor spoel vliegende vork winden machine fabrikant

1. Multiple choices of winding methods:

1. Centralized winding:

With its simple and clear structure, centralized windings have become the first choice for low-power brushless motors or for less stringent efficiency occasions. This winding method centrally winds the coil on a single magnetic pole, which is not only simple in process, but also relatively low in cost. However, simplicity is often accompanied by certain sacrifices, and the performance of electromagnetic performance, efficiency and heat dissipation performance is slightly insufficient.

2. Distributed winding:

In sharp contrast to centralized windings are distributed windings, which exhibit excellent performance with their coils evenly distributed across multiple poles. In high-power brushless motors or extremely high requirements for efficiency and heat dissipation, distributed winding is undoubtedly the best choice. Although the winding process is relatively complex and the cost is high, the improved electromagnetic performance, efficiency optimization and excellent heat dissipation capabilities it brings make all of this worth the money.

3. The Art of Automation and Handcraft: The Duo of Winding

In the wave of mass production, automatic winding stands out with its efficient and accurate characteristics. Through automated equipment, winding speed has been significantly improved and consistency has been strongly guaranteed. However, behind this is the high equipment costs and complex maintenance requirements. In contrast, although manual winding is less efficient and has a slightly inferior consistency, its flexibility and adaptability to special customized motors are incomparable to automated winding.

2. In-depth analysis of working principles

The working principle of the brushless motor stator winding machine is inseparable from its precise mechanical structure, wire feeding device and control system. As the core component, the winding head is responsible for accurately winding the copper wire in the stator groove; the stator fixture ensures the stability of the stator during the winding process. The wire feeding device provides a solid guarantee for the winding process by accurately controlling the conveying speed and tension of the copper wire. Behind all this, the accurate command of the control system is inseparable. Whether it is a PLC or a CNC system, it can accurately control the winding path, number of turns, speed and other parameters to meet the needs of different stator models.

Buitenste Stator Trillen Plaat Voeden Vacuz volledig automatische BLDC Brushless Drone UAV koelventilator motor spoel vliegende vork winden machine fabrikant

To sum up, brushless motor stator winding technology provides strong support for the performance improvement of brushless motors with its diversified winding methods and precise working principles. Whether it is the pursuit of simple centralized winding or the distributed winding that is performance-first; whether it is efficient and accurate automatic winding, or flexible and changeable manual winding, they all play an irreplaceable role in their respective fields. Behind all this, the precise mechanical structure of the winding machine, the wire feeding device and the coordinated combat of the control system is inseparable.

E-mail: sales@vacuz.com