Motor stator winding can not be separated from the winding machine automation equipment, many machines are not only bad quality, stability is not pass, and the intelligent effect is not good, then how to motor stator winding machine more intelligent? What are the conditions that you need to have, Vacuz give you an introduction to it! I hope it can help you!

First, the advanced control system

1. High-performance controllers: In addition to independent research and development of special controllers, you can consider the integration of advanced PLC (Programmable Logic Controller) or IPC (Industrial Personal Computer), combined with high-speed data processing chip, to enhance the system’s real-time response and computational capabilities.

2. Intelligent algorithms: develop special software, integrate machine learning algorithms, optimize winding parameters through historical data analysis. Establish a model to predict the effect of winding, real-time adjustment to improve accuracy and efficiency.

Second, high-precision sensors and detection technology

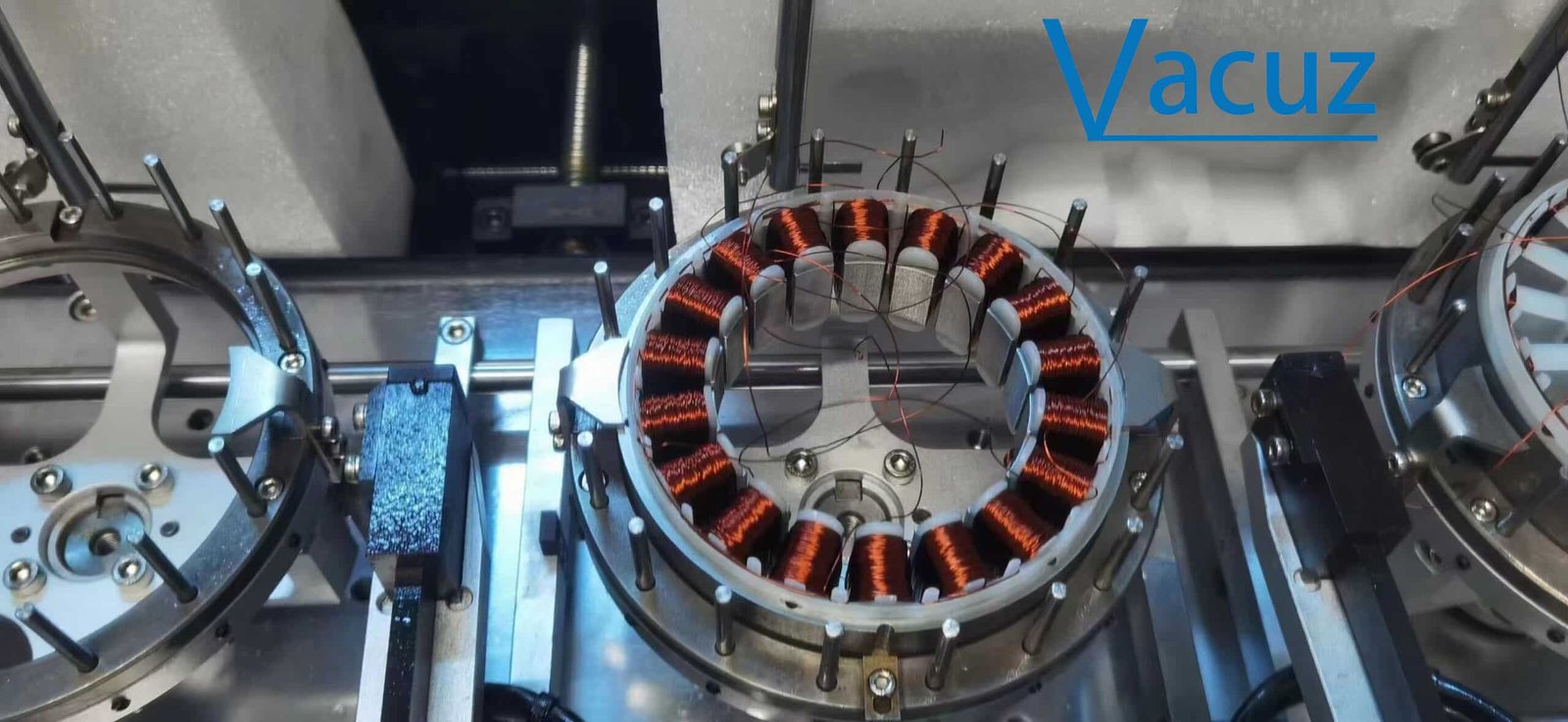

1. High-accuracy sensors: use high-accuracy tension sensors, photoelectric encoders, linear displacement sensors, etc., to ensure the accurate capture of the parameters in the winding process.

2. Intelligent detection technology: introduce machine vision system, combined with AI image recognition technology, to realize the automatic detection of winding quality. At the same time, laser sensors can be used for high-accuracy size measurement to improve detection accuracy.

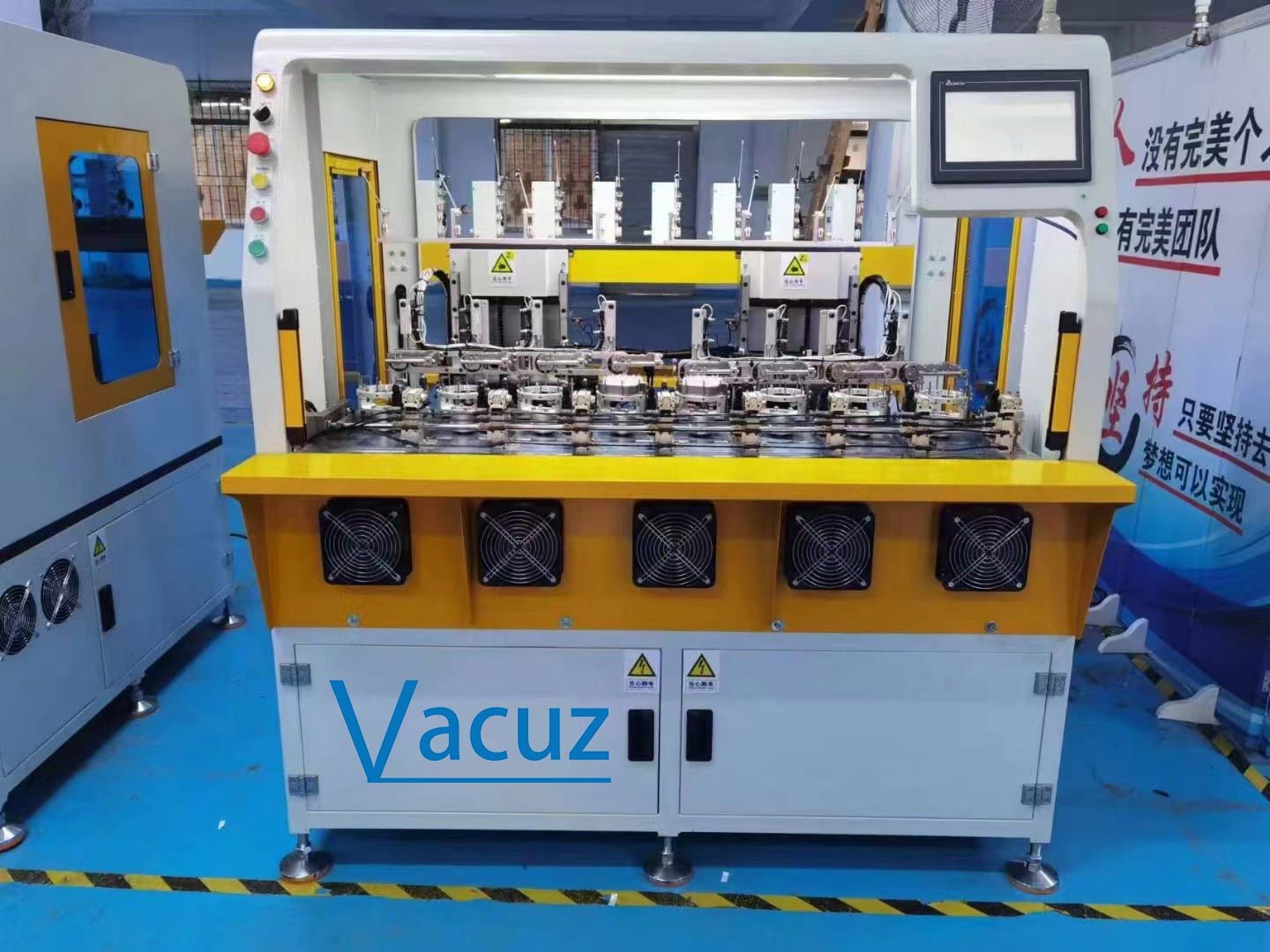

III. Highly automated and modularized design

1. High degree of automation: develop fully automatic winding system, integrating automatic loading and unloading, automatic wire changing, automatic inspection and other functions. Adopt industrial robot technology to improve automation level and production efficiency.

2. Modularized design: design modular mechanical structure and electrical system, so that different functional modules can be independently upgraded or replaced. This can quickly adjust the equipment configuration according to the needs of different stator products.

Friendly human-computer interaction interface

1. Simple and clear operation interface: adopt intuitive graphical interface design, combined with icons and text instructions to reduce the difficulty of operation. Detailed operation guide and video tutorials are provided to help operators get started quickly.

2. Multiple interaction modes: In addition to the touch screen, we can also consider adding voice interaction functions to support voice command input and feedback. At the same time, provide personalized operation interface setting options for different operators.

V. Stable and reliable hardware foundation

1. High-quality hardware components: high-performance servo motors, drives, screws, guide rails and other components of internationally recognized brands are selected to ensure the stability and durability of the equipment.

2. Strict manufacturing process: the implementation of ISO quality management system to ensure that every step from raw material procurement to production and processing meets the high standard requirements. Strengthen the quality inspection and testing links to ensure that each piece of equipment is strictly tested before leaving the factory.

Perfect after-sales service and maintenance system

1. Professional after-sales service team: establish a professional after-sales service team to provide 24-hour online technical support and remote troubleshooting services. Provide users with regular training and technical consulting services.

2. Easy-to-maintain design: Design the mechanical structure that is easy to disassemble and assemble, which is convenient for maintenance and upkeep. Provide detailed maintenance manuals and maintenance video tutorials to help users quickly solve common problems. At the same time, establish a fast supply channel for spare parts to ensure that when the equipment fails, the parts can be replaced in time to resume production.

How can motor stator winding machines be smarter? Vacuz above is some common methods, I hope these tips can help you!

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]