For commonly used automation equipment, commonly used motors are servo motors and stepper motors, can be used with, can also be used alone, online friends have asked, servo motor can replace the stepper motor? The following Vacuz simple to give you an analysis of it! I hope it will help you!

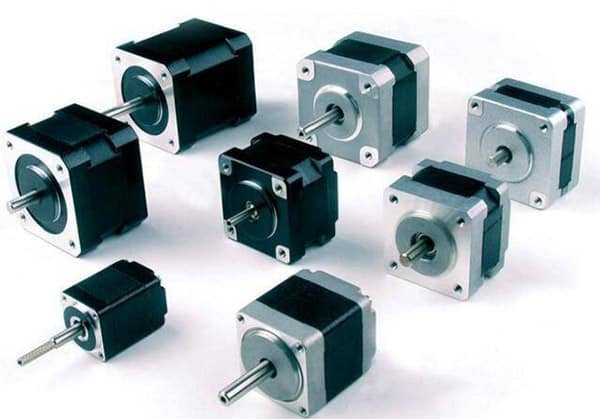

Servo motors and stepper motors are control motors, mainly used for precision positioning control purposes, especially servo motors, commonly used in CNC systems, generally using the controller + driver + servo motor (stepper motor) + coupling + screw vice + guide, servo motor and stepper motor speed can be adjusted according to the pulse frequency in a wide range.

The difference between them is that servo motors are closed-loop control, while stepper motors generally use open-loop control. Servo motors are more accurate and more expensive than stepper motors!

Servo motors and stepper motors are used for positioning applications. Servo motors and stepper motors are special motors that can precisely control speed, but they have different speed control principles. Servo motors are closed-loop control, which means that the motor speed is measured in real time; motors are open-loop control, where the input of a pulse stepper motor will rotate around a fixed angle, but not measure the speed.

Generally speaking, servo motors are one level higher than stepper motors, generally used for high-precision machinery, stepper motors are generally used for simple mechanical movement. So the conclusion is that servo motors can replace stepper motors, and stepper motors can not necessarily replace servo motors, of course, in addition to some special range of places.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]