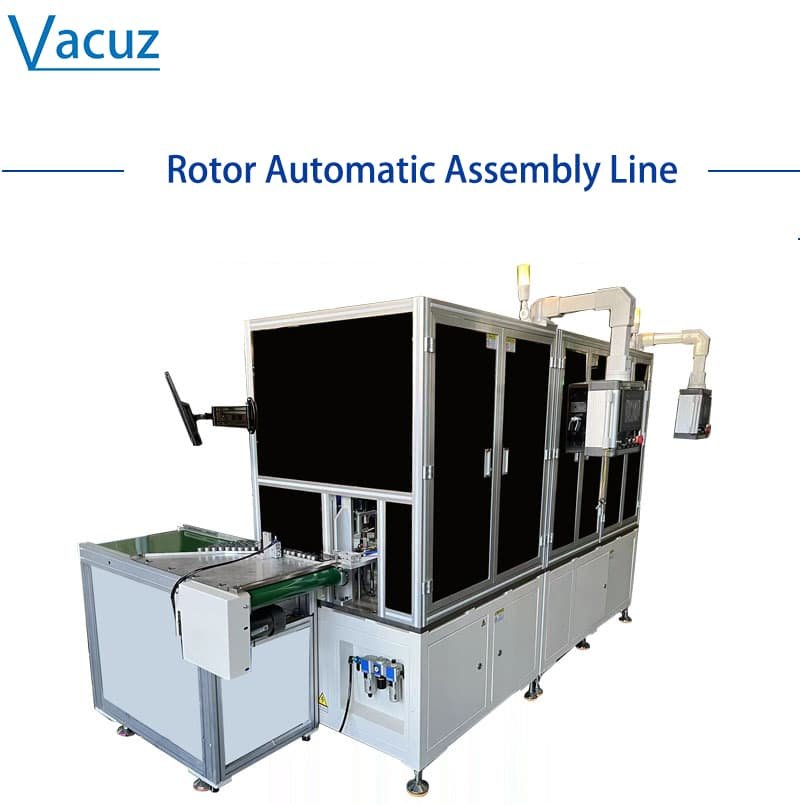

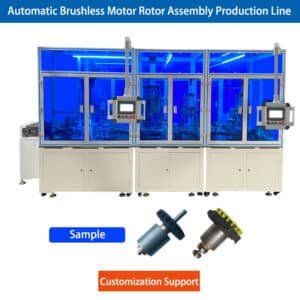

Rotor is an important part of brushless motor, now many manufacturers are using automatic production line to assemble, high production efficiency, product quality is also better, but if the production line failure, or maintenance is not in place, it is easy to have problems, rotor assembly also encountered trouble, may lead to product failure, then the rotor automatic production line assembly common problems and what are the solutions? Vacuz briefly introduce it to you! Hope it can help everyone.

1. Check all power, gas and hydraulic sources of the rotor automatic production line situation.

When checking the assembly of the rotor automatic assembly line, check the power supply, air source and hydraulic source situation to ensure that all parts are running normally, and problems need to be checked and dealt with in a timely manner.

2. Confirm whether the sensor position of the rotor automatic line is shifted.

After the rotor automatic production line runs for a long time, some sensors or fixtures are prone to some minor changes and small problems in sensitivity, so before the machine runs, make sure to check the sensor position changes to ensure normal operation.

3. Relays, flow control valves and pressure control valves

Relays are similar to magnetic induction sensors and have long-term grounding problems that affect the normal use of the circuit and need to be replaced. The pneumatic or hydraulic system of the flow line, the throttle port of the pressure valve and the regulating spring are loose or sliding due to the vibration of the flow line, and require frequent maintenance in daily use.

4. Check the connection of electrical, pneumatic and hydraulic circuits

Check the circuit status of the equipment to see if there is a disconnection problem, check whether the branch air pipe is broken, check whether the hydraulic oil pipe is blocked, the air pipe should be replaced immediately if it is seriously damaged, and the hydraulic oil pipe also needs to be replaced if there is a problem.

The above is the rotor automatic production line assembly common problems and solutions, the normal and stable operation of the equipment, the production schedule issues, so be sure to do a good job of maintenance work, problems should be timely check feedback.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]