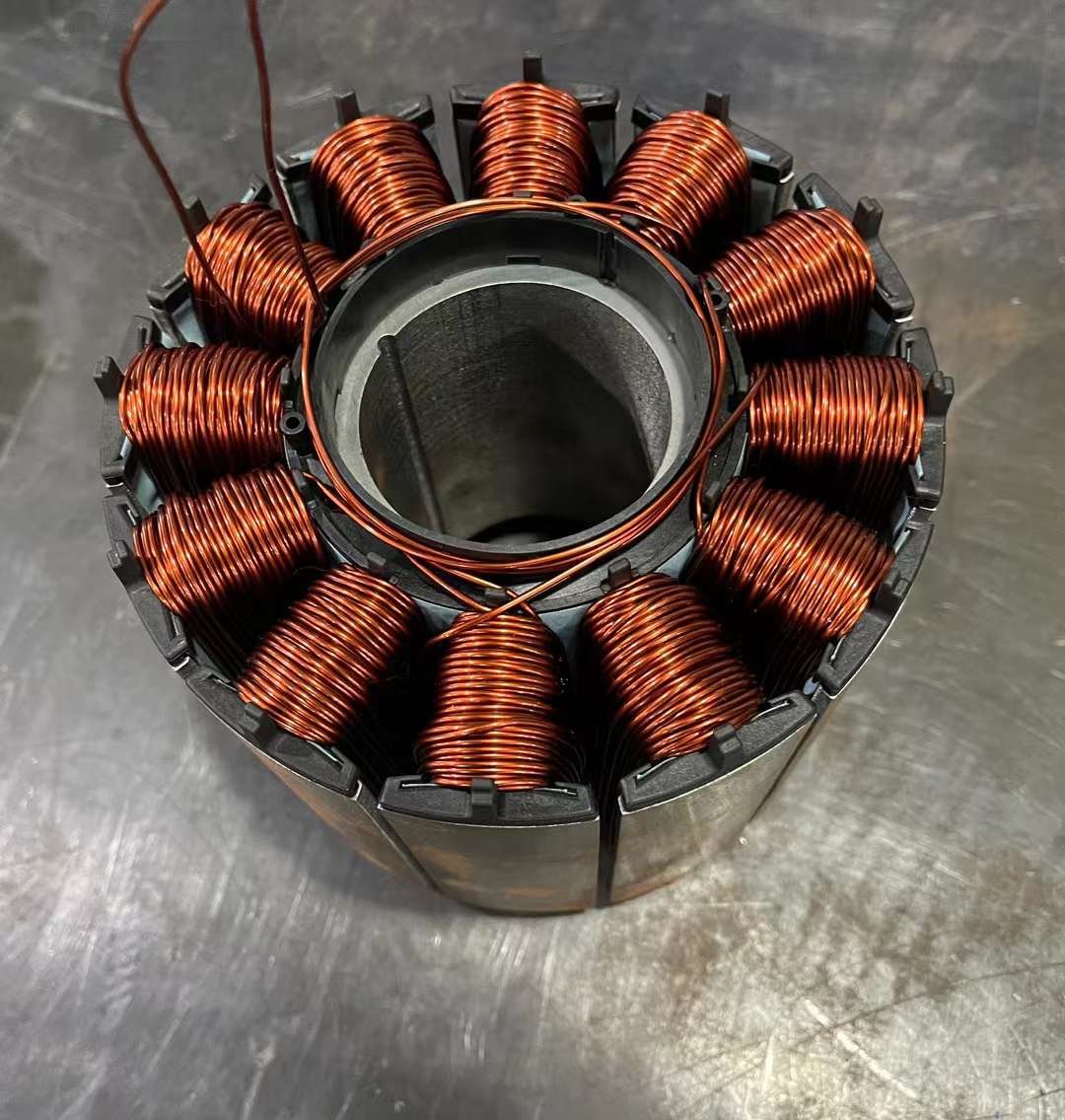

The common flying fork winding machine, generally most of the single-wire winding, such as aeromodels, drones, cooling fans, fascia guns and other brushless motor stator products; but there are also many products, such as robots, planting machines, and other stator products are also multi-wire and winding, so the flying fork multi-wire and winding process is not difficult? How to make the wiring tightly organized, Vacuz give you an introduction to it! I hope it can help you!

In fact, for the flying fork winding method, whether it is a single line and multiple lines and winding, there are difficult to wind, there are also simple, most of the ordinary winding, there is no special requirements, generally easier, so the difficulty of winding, mainly according to the specific circumstances of the stator, mainly in the following areas:

1. wire diameter size: the thicker the diameter of the wire, the greater the difficulty of winding, but also more likely to hurt the line, the smaller the diameter of the wire, relatively easier to wind, but also pay attention to the problem of broken line hurt line.

2. How many enameled wires and winding: the more the number of enameled wires, the greater the difficulty of winding, there is generally an upper limit, 0.3mm below the diameter of the wire can be about 30 wires and winding, more than too much, you need to re-formulate the winding program.

3. Stator height: the higher the stator, the easier it is to scrape the winding line, the thick line is easy to hurt the line, the line is easy to break the fine line, the winding speed must be slow.

4. Stator slot size: slot size determines how many lines through, if more lines and winding, the line can not be stuck in or barely stuck in, it is easy to hurt the line.

Of course, in addition to the above, the configuration of the winding machine equipment is also very critical, here will not be introduced.

How to make the line more tight? In fact, in addition to the configuration of the winding, whether it is the commissioning of the machine, the commissioning of the tension, or the customization of the winding program, are very critical, the line is tight at the same time, but also to avoid injuring the line, broken line, stacked line, skipping and so on.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]