A brushless motor winding machine is mainly divided into two kinds of internal and external winding, according to the different requirements of the stator, the winding needs are also different, such as some requirements for winding fine wire, some requirements for winding thick wire, then brushless motor winding machine winding fine wire to pay attention to what? Vacuz will analyze it for you!

When winding wire with brushless motor winding machine, you need to pay attention to the following points:

1. Tension control: fine wire is generally about 0.1mm, a little force will break. Therefore, you must be careful when winding, especially the tensioner must be controlled, not too tight, not too loose!

2. Winding speed: Fine wire winding speed is generally faster, but it should be controlled within a certain speed range.

3. Winding method: Before winding, you need to plan the winding of the stator product, calculate the coil surface area, the adaptability of the winding tooling, winding design, etc. The correct winding method can help reduce the risk of wire breakage.

4. Machine Configuration and Maintenance: Check whether the machine configuration meets the requirements, ensure that the precision of the mold is high enough to avoid burrs and other problems. Perform regular maintenance on the machine, including cleaning and lubrication to keep it in good working condition.

If the brushless motor winding machine breaks when winding fine wires, the following measures can be taken:

1. Check the tensioner: check whether the tensioner is adjusted correctly, if the tension is too tight, it needs to be loosened appropriately, if the tension is too loose, it needs to be tightened.

2. Check the winding speed: confirm whether the winding speed is too fast, if the speed is too fast, the speed should be reduced appropriately.

3. Check the auxiliary accessories: Check whether the auxiliary accessories such as over-winding wheel, wire nozzle and wool felt have impurities or are damaged. If problems are found, the impurities should be removed or the accessories should be replaced in time.

4. Check the quality of enameled wire: Make sure the enameled wire used is of good quality to avoid wire breakage due to enameled wire quality problems.

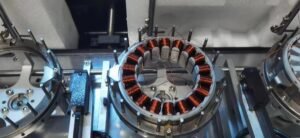

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

What should I pay attention to when winding fine wires for brushless motor winding machine? Vacuz above is a simple introduction, I hope these tips can help you!

E-mail: sales@vacuz.com