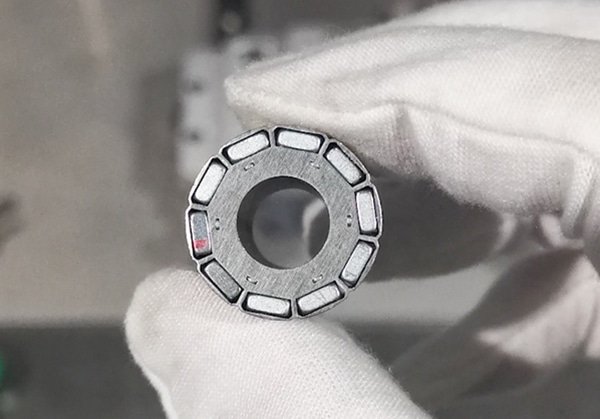

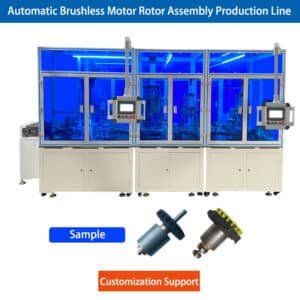

Stator and rotor are the core part of brushless motor, most of them used to be installed manually or semi-automatically, which is inefficient. Now we use automatic assembly line to take out the assembled finished products for discharging, and the whole assembly process does not need manual participation, it not only has the advantages of high assembly efficiency, good assembly effect and high assembly precision, but also greatly reduces the labor intensity of workers and lowers the labor cost of enterprises.

Brushless motor rotor automatic assembly line is commonly used for automatic assembly of rotor of household electrical appliances motor, electric tools, water pump, etc. It can realize automatic assembly of rotor, riveting shaft, turning outer circle, applying antirust oil, clamping spring and bearing, etc. It is easy and fast.

1. Adopt advanced imported PLC controller control, with high control precision.

2. The slideway adopts free falling material for transmission.

3. Simple structure composition of the whole equipment, convenient for later maintenance.

4. Wide range of application, power tool motors, pump motors, stepper motors and other rotors are applicable.

5. Stable operation of the equipment, good coordination between the components, quality and efficiency is guaranteed.

6. Can be non-standard customized, professional and unique humanized design, so that your production worry-free.

The above is the characteristics of brushless motor rotor automatic assembly line, with the continuous development of technology, motor production technology is more and more advanced, I believe that in the future, artificial intelligence will be more powerful!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]