To achieve optimal winding and arranging of motor stator winding machines, optimization is required in six core areas: equipment hardware, control algorithms, process parameters, environmental management, real-time monitoring, and personnel skills. The following is a detailed summary of Vacuz’s specific implementation methods, which we hope will be helpful!

I. Equipment Hardware Optimization: High Accuracy and High Responsiveness

1. Transmission Component Upgrade

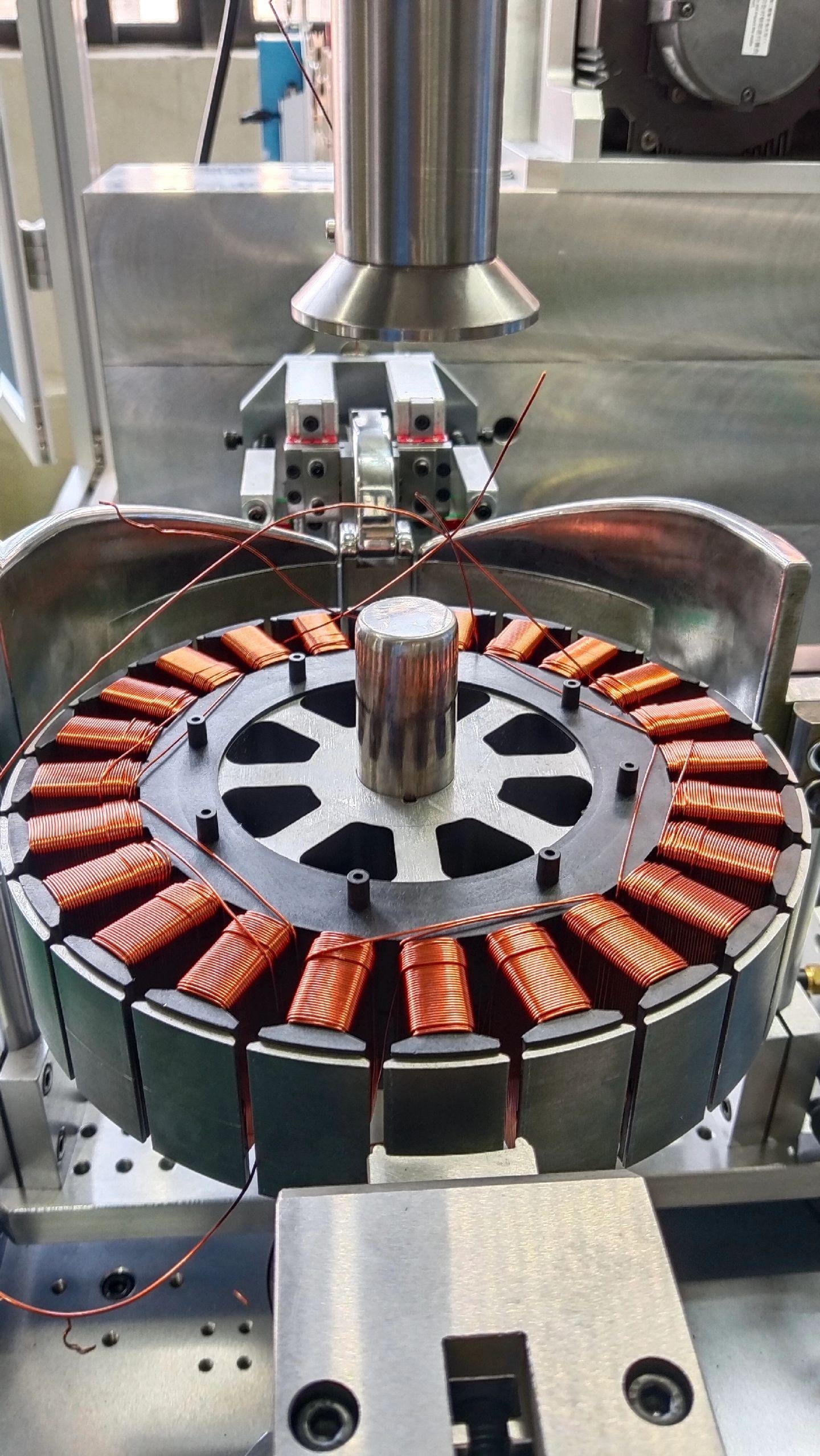

A ball screw + linear guide combination is used to control positioning error within ±0.01mm.

A servo motor with a rated speed of ≥3000 RPM, combined with direct drive technology (such as a torque motor), can achieve spindle speeds exceeding 5000 RPM.

2. Enhanced Dynamic Response

The wire arranging mechanism structure is optimized through finite element analysis to reduce inertial mass.

The nozzle is constructed of high-performance materials and equipped with pneumatic/electric fine-tuning mechanisms to compensate for wire diameter variations in real time.

3. Mold and Device Precision

The mold is constructed of high-strength materials (such as alloy steel) to prevent deformation.

A laser calibrator monitors the cable routing trajectory, and immediate adjustments are made if deviations exceed ±0.05mm.

II. Control Algorithm Innovation: Intelligent Path and Speed Planning

1. Path Optimization Algorithm

A three-dimensional mathematical model is built based on the stator slot profile, and a special algorithm is used to generate a smooth cable routing path, reducing bending stress in the wire.

Dynamically adjust the cable routing spacing and number of winding layers for different slot profiles to ensure uniform slot fill.

2. Look-ahead Speed Control

Preemptive deceleration is implemented at path corners to prevent wire throwout and overlap.

An integrated vibration suppression algorithm injects notch filters at critical frequencies to reduce resonance effects.

3. Thermal Error Compensation

An infrared thermal imager monitors the temperature distribution of the motor and lead screw in real time to create a thermal deformation model.

For every 10°C increase in temperature, the system automatically compensates for positioning errors by 0.005mm.

III. Process Parameter Optimization: Tension and Wire Management

1. Intelligent Tension Control

A tension sensor is installed to monitor and adjust winding tension in real time: 0.5-5N for copper wire and 0.3-3N for aluminum wire.

A closed-loop feedback system automatically optimizes the tension curve based on wire material, diameter, and winding speed.

2. Wire Path Simplification

The winding and wire feeding processes are optimized to reduce wire bends and friction losses.

A single-layer winding with a short path design saves 5%-10% of enameled wire.

3. Parameter Database and Adaptive Optimization

A process database is established to support rapid parameter matching.

A reinforcement learning algorithm is introduced to automatically adjust parameters based on real-time production data.

IV. Environmental and Process Control: Refined Production Conditions

1. Constant Temperature and Humidity Environment

The workshop temperature is 20±2°C and the humidity is 50±5% to prevent softening of the enameled wire insulation.

Install shock-absorbing pads and soundproof covers to reduce vibration and noise interference (vibration amplitude ≤ 0.02mm).

2. Cable routing method adaptation

Parallel routing: Suitable for applications requiring high-magnetic field uniformity, requiring high-precision guide rails and sensors.

Spiral routing: Improves space utilization, requiring a high-power motor and high-speed spindle.

Cross-link routing: Optimizes magnetic field distribution, requiring a PLC to implement complex routing algorithms.

V. Real-time Monitoring and Fault Prevention: Full-process Quality Control

1. Machine Vision Inspection

Deploy high-speed cameras and image processing algorithms to achieve a defect detection accuracy of ≥ 99.5%.

Integrate multi-source sensors to predict equipment failures (such as tensioner wear) through machine learning.

2. Operator Skills Training

Regularly organize commissioning personnel training to ensure that cable spacing tolerances are within ±0.03mm.

Strengthen quality awareness education to enhance troubleshooting capabilities.

VI. Implementation Results and Value

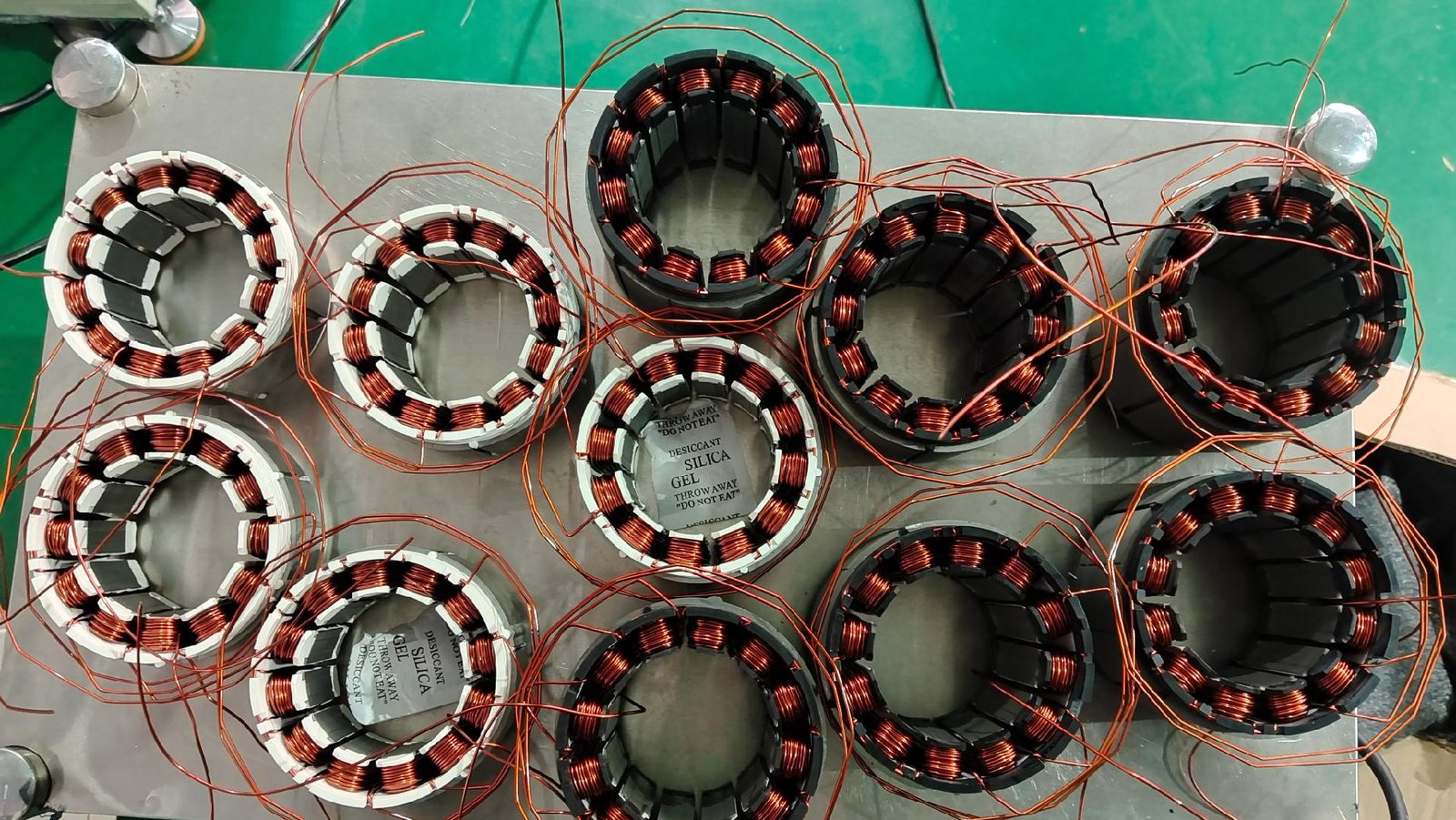

Wire Trapping Accuracy: Positioning error ≤ ±0.01mm, slot fill rate uniformity improved by over 20%.

Production Efficiency: Winding speed increased by 30%, idle time reduced by 15%.

Product Quality: Wire breakage rate reduced to below 0.1%, motor noise and vibration reduced by 10%-15%.

Equipment Lifespan: Through thermal error compensation and regular maintenance, service life is extended by 20%-30%.

Summary:

Suitable winding and tracing technology for motor stator winding machines requires high-precision hardware, combined with intelligent control algorithms and refined process management. Real-time monitoring and personnel skills development ensure quality throughout the entire process. This comprehensive optimization solution not only improves production efficiency and product quality, but also provides motor manufacturers with a more competitive solution.

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]