Previously, the production of motor motors without automated equipment, mainly by manual to solve the problem, inefficient, defective products; now many motor manufacturers began to use automated intelligent equipment, motor parts assembly in one go, efficiency greatly improved, but compared to manual, automated equipment preparation work is a little more complex, not only need to test, but also pay attention to the articulation of the stations, especially the pre-assembly inspection Vacuz take a look at it!

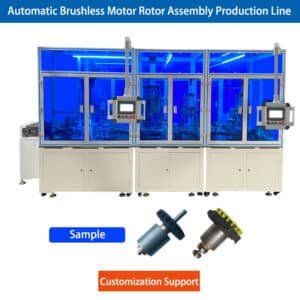

Automatyczna linia produkcyjna do montażu wirników silników bezszczotkowych

1. Pay attention to inspect and clean the motor parts to ensure that the parts are intact and clean.

2. Pay attention to check the inner cavity of the stator and the surface of the rotor to ensure that it is clean and free of dirt and other impurities.

3. Pay attention to check the mechanical dimensions of the rotor shaft and its parts to ensure that they meet the requirements.

4. Ensure that the motor assembly line is clean and free of foreign matter, check whether each process is operating normally, usually you can test it by running at no load before starting the machine.

Brush/Brushless Motor

The above is the brushless motor production assembly before the preparation, motor manufacturers in production, must pay attention to these basic things, to ensure that the production requirements before starting production.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com