Brushless motor stator coil winding, need to use special winding equipment, common flying fork winding machine and needle winding machine, some stator parameters are suitable for high-speed winding machine equipment, so as to increase the output, so what is the difference and difference between high-speed internal winding machine and high-speed external winding machine? Vacuz give you an analysis of how much speed can be reached? I hope it will be helpful to you!

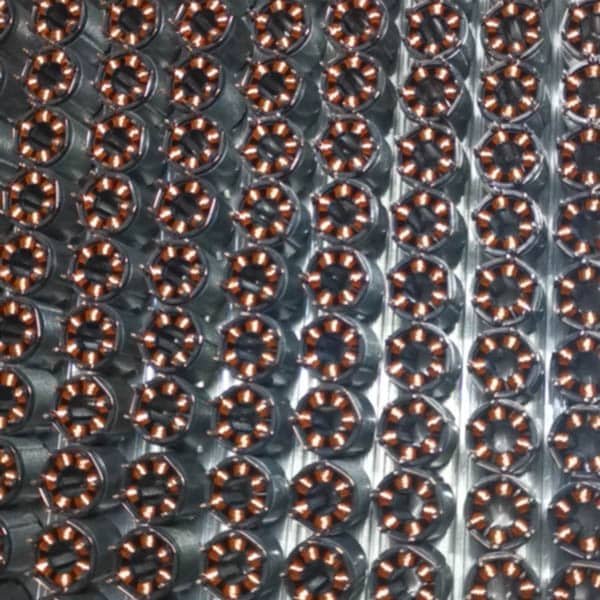

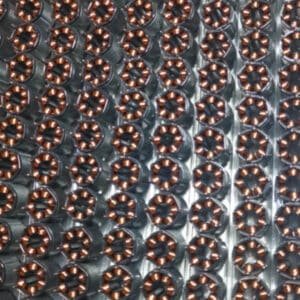

High-speed internal winding machine generally has four-station and six-station equipment, mainly for internal winding small stator, the outer diameter of the general Φ20-100mm, such as high-speed winder, electric toothbrush, rotary change, stepping motor, small pumps and other motor stator, four and six at a time, high production efficiency, the speed can reach 1000RPM, but also to achieve automatic loading and unloading, automatic cutting wire head, recycling waste wire and other functions.

High-speed external winding machine is generally mostly four-station equipment, mainly for external winding of small stators, such as models, fascia guns, drones, cooling fans and other motor stators, four at a time, production speed can reach 2600RPM or more.

Whether it is a high-speed internal winding machine or high-speed external winding machine, while improving production efficiency, but also to ensure product quality results, which requires winding machine manufacturers in the configuration and commissioning of the winding process, more efforts to ensure stable operation of equipment, winding quality is excellent.

What is the difference between high speed internal winding machine and high speed external winding machine? How much can the speed reach? The above has made a simple explanation, I hope that these tips can help you!

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]