Automatic winding machines are relatively precise mechanical equipment. Most manufacturers deliver them to your doorstep, which involves installation and calibration issues. Therefore, relevant staff must have sufficient work experience and relevant knowledge to be comparable to other electrical equipment processing equipment. Compared with , the calibration method is more complex and detailed. Next, Vacuz will tell you how to calibrate the machine!

1. The starting point of the bobbin. This specific position is tied to the top of the coil and the coil category. The specified value for the specific starting position can usually be accurately measured based on the precise measurement action of the machine control system. The operator can also use the positioning point as a reference point to make specific measurements with a measuring tape for manual measurement, and pay attention to the winding position of the coil when setting the point.

2. The understanding of the total width of the winding is the distance from the beginning of the winding to the end of the winding. Usually this value can directly reflect the winding requirements of the frame. The interference to the total width of the winding due to the slight deformation of the frame used must be taken into account. A comprehensive value should be used. This is an accurate measurement method, and the lowest value is used as the total winding width.

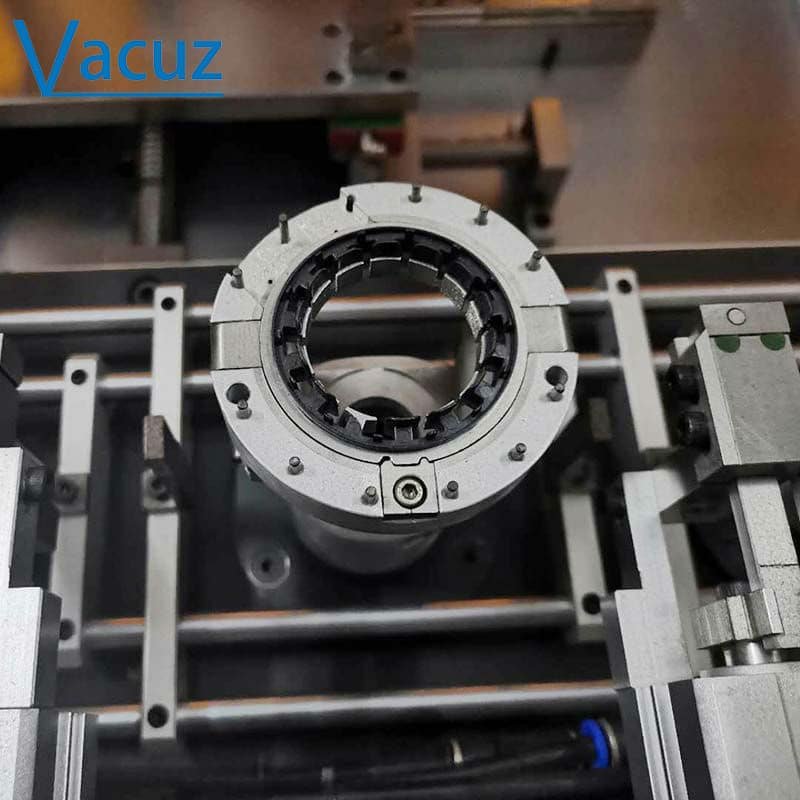

3. Before starting the winding machine, pay attention to check whether there are impurities on the workbench, mold shell fixtures, and transmission areas, whether the power supply is connected properly, whether the wire barrel is adjusted to the correct position, and whether the selected enameled wire meets the requirements. Wait and confirm that there are no problems before turning on the device.

4. Set various main parameters of the winding machine, including program number, number of turns, size of wire specification, end, start, starting point, total width of winding, groove pitch, termination direction, winding direction, etc. After the setting is completed and reset, the thread winding work begins.

5. Let the winding machine run idling first, and the speed must be slowed down to check whether there is any abnormality in each component. The basic parameters have been set. Do not wind the wire immediately to see if it is the same as your own winding needs.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]