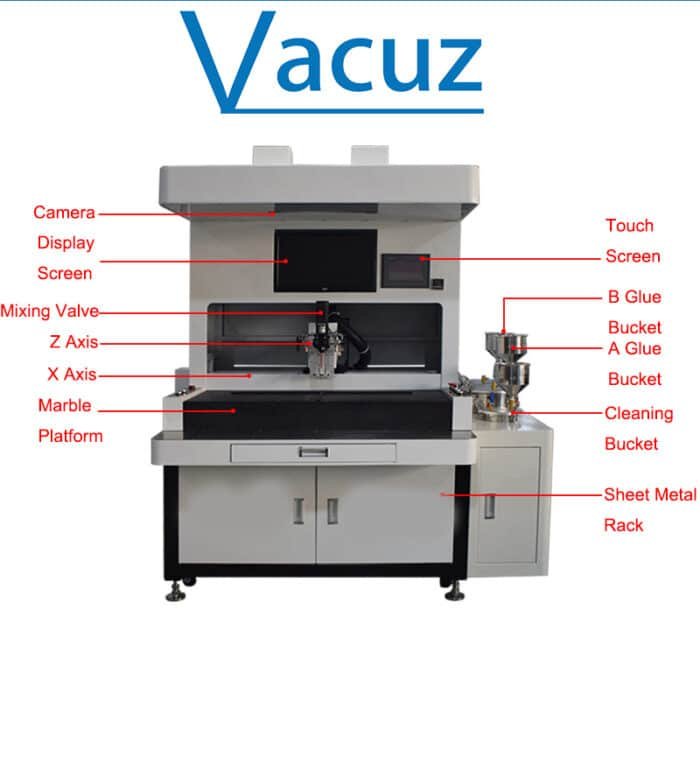

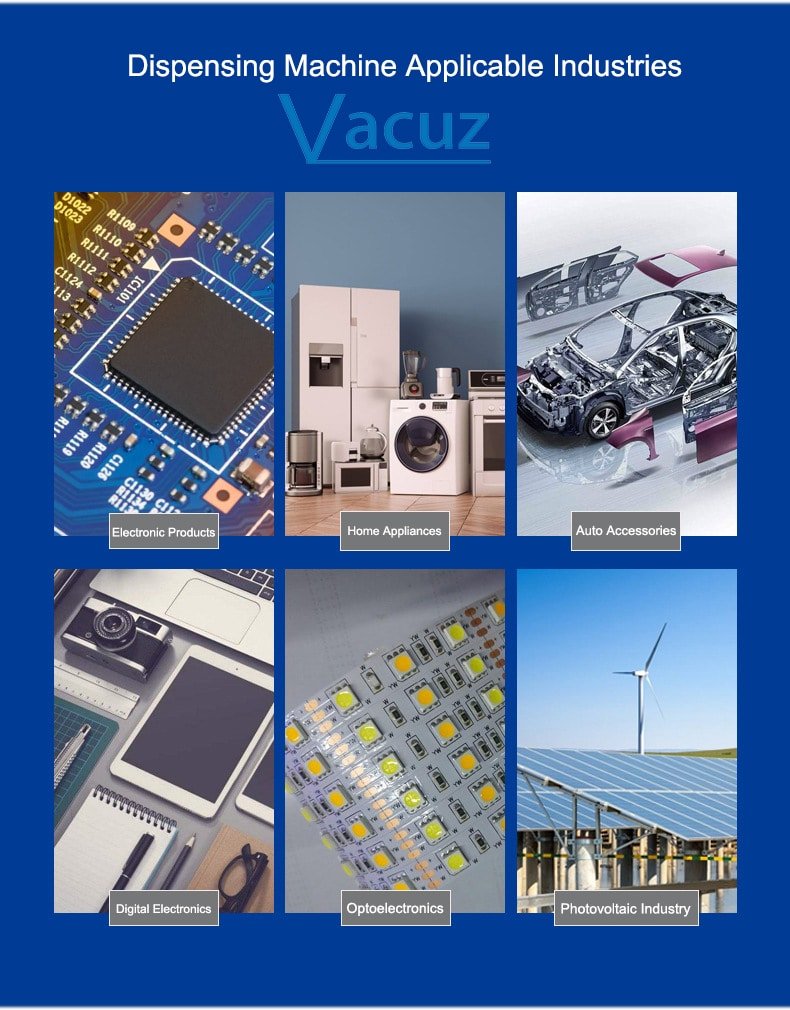

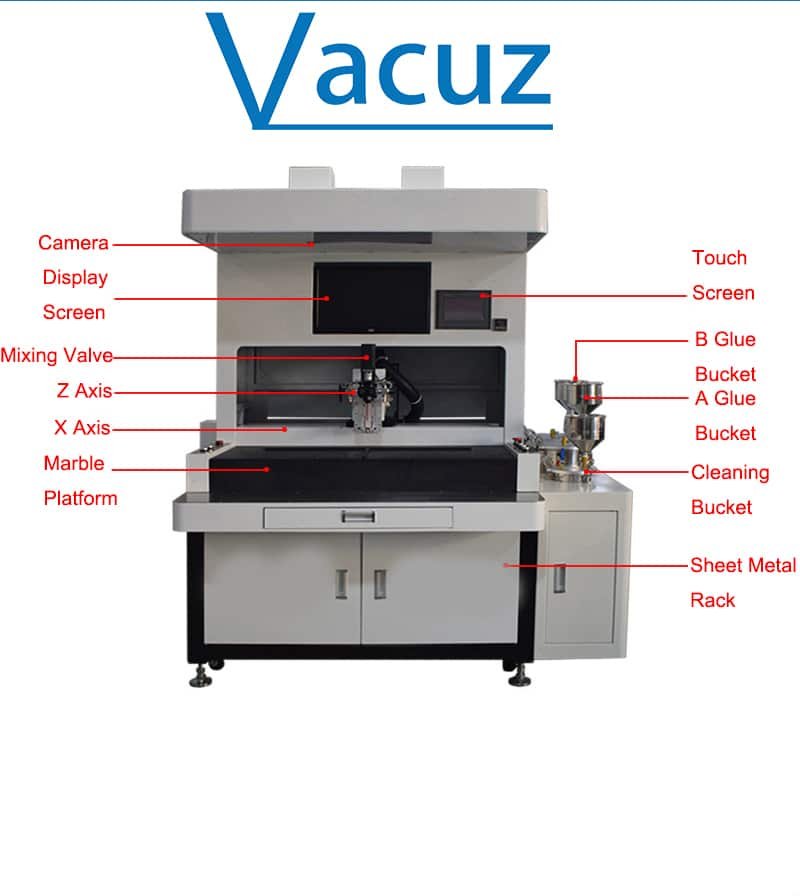

CCD Intelligent Transformer Bobbin Toroidal Coil Inductor Automatic Panoramic Vision Visual Glue Adhesive Dispensing Dispenser Machine Vision Guided Positioning

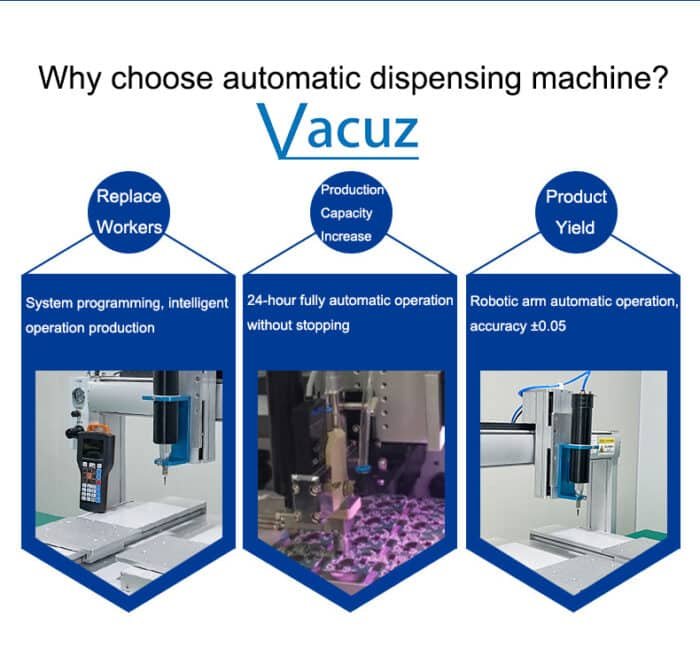

Machine Features

1. Adopt screw + servo running module, high speed running smoothly, repeat positioning accuracy ±0.01mm

2. Adopt English operation interface, easy to learn, easy to operate

3. Equipped with precision metering pump, minimum metering value 0.1G, metering accuracy ±2%

4. Optional dynamic or static mixing valve, mixing accuracy ±2%

5. The amount of glue can be set manually to ensure the quality of product dispensing

6. Automatic identification, fast imaging, arbitrary placement of products, no need for carriers

7. Automatic machine proportioning, automatic mixing of glue, which can reduce the waste of glue

8. Compared with manual dispensing, the efficiency increases 2-6 times

9. The glue barrel comes with a cleaning function, which can quickly clean the mixture and facilitate the next normal use

Main Technical Parameter

| Machine Name | Automatic Visual Dispensing Machine |

| Electronic Control System | PC+Monitor+PLC+Touch Screen |

| Effective Travel (X/Y/Z ) | 30*40*10CM |

| Number Of Cameras/Number Of Work Stations | Dual Cameras, Dual Left And Right Platforms |

| Identification Area | 30*40CM |

| Platform, Machine Weight | +Marble Platform 670Kg |

| Tank Capacity | A/B Glue Bucket:25L, Cleaning Bucket:5L |

| Number Of Dispensing Heads | Depending On The Product, 2-10 Nozzles Can Be Made |

| Glue Proportion | 1:1-10:1 Fixed Ratio Adjustable |

| Measurement Method | Gear Pumps/Screw Pumps |

| Measurement Accuracy | Glue Quantity±2%,Ratio:±2% |

| Operation Method | Imported Linear Guide + Screw + Servo |

| Running Track | Point, Line, Box, Arc, Circle |

| Operation Speed, Accuracy | Max 500mm/s (Displacement), ±0.01mm (Displacement) |

| Mixed Mode | Static Mixing / Dynamic Mixing |

| Machine power supply/power | 220v/50HZ 2000W |

| Input Air Pressure Range | 0.5-0.8MPa |

| Machine Dimension | 1890*1640*1870mm |

Company Information

Vacuz Machine Factory was founded in May 2007, located at Dongguan City in Guangdong Province. It is a professional manufacturer engaged in the research, development, production, sale, and service of automatic winding machines, bobbin winding machine, transformer winding machine, motor winding machine, wireless coil winding machine, SQ common mode choke inductor winding machine and other non standard winding machines . Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as the Middle East, Europe, Africa, Asia, and North America. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. Quality is our culture! Hope for your cooperation soon!

Packing & Shipping

1.Port: Shanghai/Shenzhen or your choice

Package and transport

General package(Paper carton or plastic bag): For small goods, Package it with form and pack paper to guarantee unbroken during the transport.

Wooden case package: For larger scale goods as machine equipment etc, we have special skilled carpenter, who would make the proper wooden case with exact thickness,density,length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent crack and shock. We will inform you the delivery note. You just need to wait for phone call, then pick up the goods at the nearest logistic station .(Please let me know in advance if you want get the goods at home.)

Vacuz Service & Strength

Service tenet

Provide you the best service with “fast + satisfactory + safe”.

Warranty period

12 months long after the user received the product.

Warranty items

Only for abnormal breakdown caused by the machine design or manufacture defect,

free repair and accessory will be provided.

Technology service ability

All service engineers with many years experience are gotten special technology training, who can deal with various breakdown problem.

Guide the user to use accurately and how to maintain the product.

Provide free consultation about production process technology of electronic products.

Service after sell

In order to guarantee the machine used normally, we’d have training on how to operate, use and maintain our product by English manual, video, guiding on line.

Use instruction

Apply for the right complete size of product, otherwise, the wrong dimensions will affect the use effect.

Do ensure using the product accord to the use instruction completely.Do not exceed the scope of application of the products.

Maintain the product after use,Damp proof, rust proof, leak proof, explosion-proof, regular maintenance and inspection should be taken care. All done help to extend the use period.

User document management

Establish perfect user document management in EPR system, Every product running details would be followed to manage. The users would be taken good care.

About product

1. Product photo: All product photos are taken by real product, There is the color aberration between the product and photo, which is caused by shoot light, product size, manual technology and computer display etc. It’s not quality problem. Parts of products

are changed in appearance due to technology revolutionary and process improvement. SanShine would ensure the parameter of product is unchanged, The product couldn’t affect to use.

2.Product size: All parameters are all measured by manual just for reference. There is a small deviation due to the difference of measure tools, lot products and produce process. Real size should be accordance with the final delivery product.

3.Quality inspection: All products should be inspected strictly before shipment. Ensure the good function and appearance.