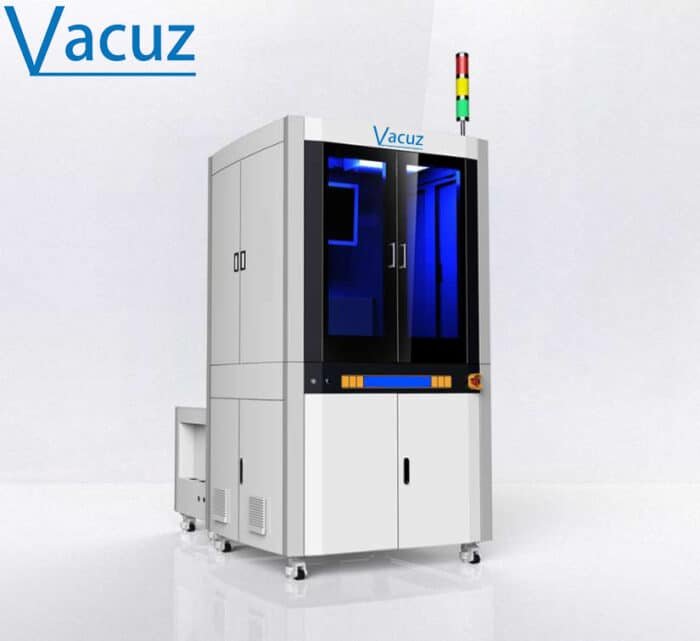

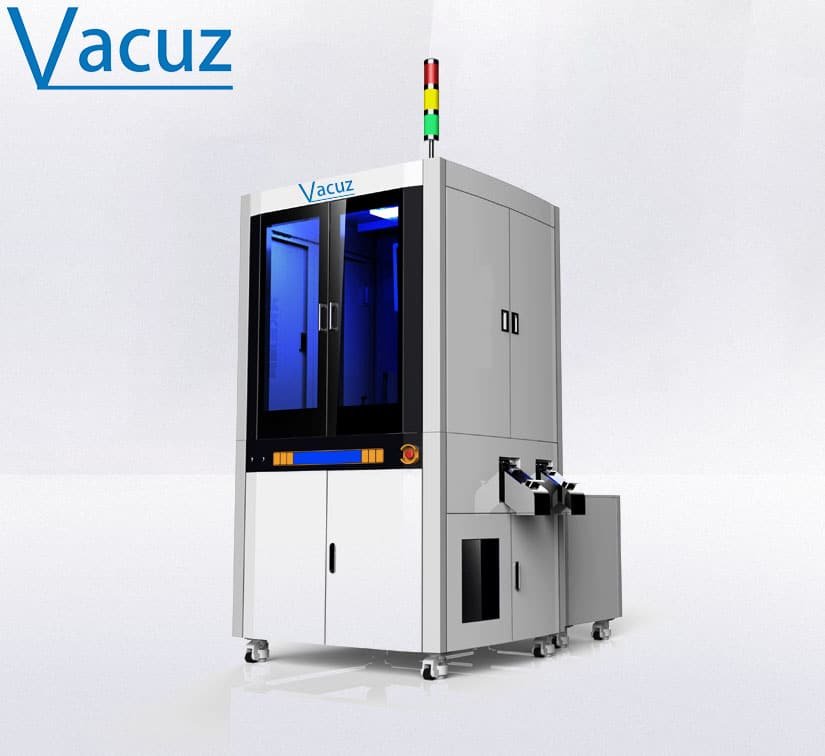

Vacuz 6 Sides AI CCD Molding Common Mode SMD SMT Chip High Frequency CD NR Inductor Automatic Magnetic Core Resistor Capacitor Coil AOI Visual Inspection Detection Machine

Machine Feature

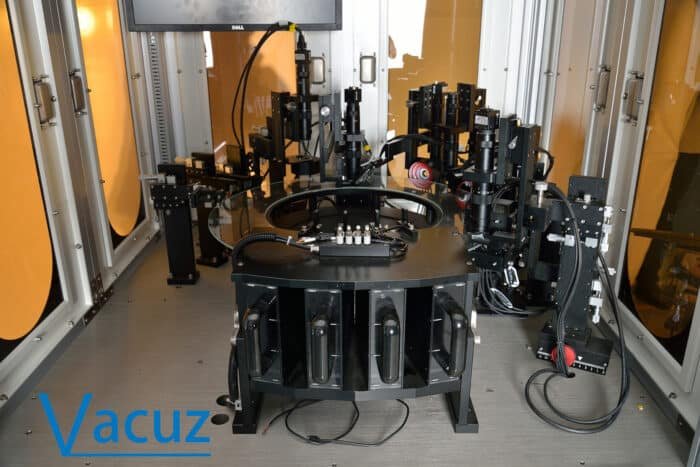

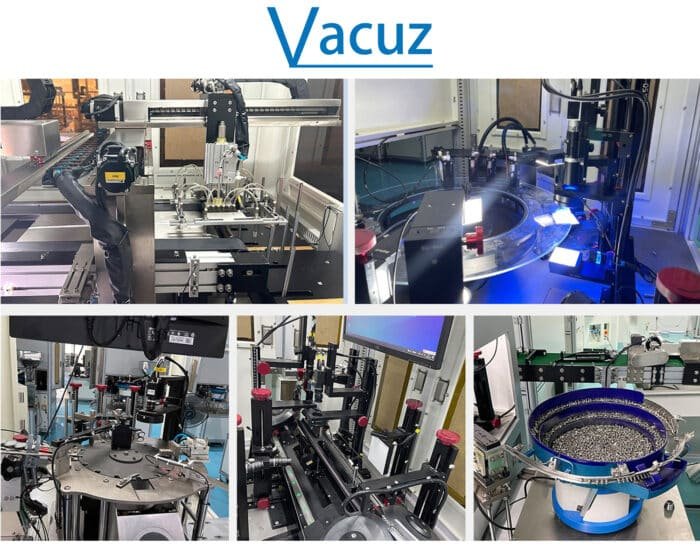

Vacuz multi-surface appearance inspection equipment uses six sets of intelligent industrial cameras and the world’s most advanced AI visual image processing method to perform visual image processing and analysis on the six-surface images of the product, and classifies the products based on the analysis results (automatic classification of good/bad products). It is a highly efficient electronic component appearance screening equipment.

Machine Function

An inductor is a component that can convert electrical energy into magnetic energy and store it. The structure of an inductor is similar to that of a transformer, but it has only one winding. An inductor has a certain inductance, and it only hinders the change of current. If the inductor is in a state where there is no current flowing through it, it will try to hinder the current from flowing through it when the circuit is connected; if the inductor is in a state where there is current flowing through it, it will try to maintain the current unchanged when the circuit is disconnected. Inductors are also called chokes, reactors, and dynamic reactors.

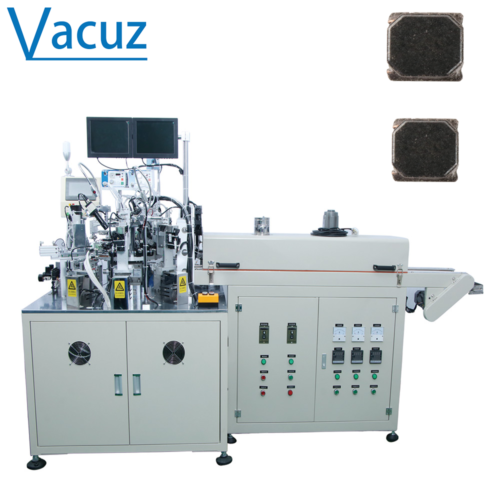

Inductors are generally composed of a skeleton, windings, shielding covers, packaging materials, magnetic cores or iron cores, etc. After the general packaged inductors are formed, they need to be tested by testing equipment for surface damage, cracks, rust spots, exposed copper, dimensions, etc., so as to screen out defective products.

Inductor testing equipment, the main testing contents of inductor products are: size, surface damage, cracks, depressions, rust spots, pinholes, bruises, poor rubber coating, deformation, core cracks, lack of glue, dirt, cover damage, glue overflow, lead deviation, lead too long or too short, copper wire defect, exposed copper, black spots, etc.

Due to the small size of the inductor, its surface defects are difficult to identify by human eyes, and it is necessary to use optical visual inspection equipment for detection. At present, it is basically a combination of CCD camera and LED light source for visual recognition. Since the accuracy of traditional inductor detection equipment is not very high, CCD inductor automatic detection equipment is used to detect inductor products. It has fast detection speed and high accuracy, which perfectly replaces manual detection, improves product production efficiency and reduces production costs.

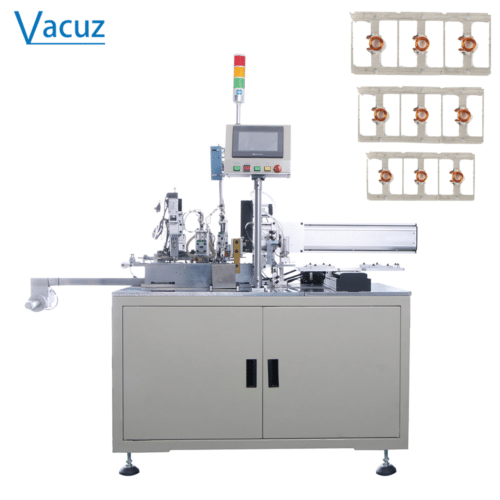

1. Appearance inspection of winding inductors and molding inductors

2. Magnetic core appearance inspection

3. Chip resistor and capacitor appearance inspection

Machine Parameters:

| Model | VAC-2100 |

| CCD module | Six 750-fps color cameras |

| Lens and architecture | Zoom lens |

| Software system | Vacuz AI System |

| Light source system | 3D Light Source |

| Running speed | 11000pcs/min |

| Feeding mechanism | Vacuz self-developed high-speed feeding system |

| High speed solenoid valve | More than 5 billion times |

| Material guide mechanism | Vacuum electrostatic guide module |

| Equipment size (L*W*H) | 1000mm*950mm*1850mm (can be customized according to customer needs) |

| Machine weight | 580KG |

| Voltage | 220v |

| Air pressure | 0.5-0.8MPa |

Machine Application

Company Information

Vacuz Machine Factory was founded in May 2007, located at Dongguan City in Guangdong Province. It is a professional manufacturer engaged in the research, development, production, sale, and service of automatic winding machines, bobbin winding machine, transformer winding machine, motor winding machine, wireless coil winding machine, SQ common mode choke inductor winding machine and other non standard winding machines . Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as the Middle East, Europe, Africa, Asia, and North America. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. Quality is our culture! Hope for your cooperation soon!

Packing & Shipping

1.Port: Shanghai/Shenzhen or your choice

Package and transport

General package(Paper carton or plastic bag): For small goods, Package it with form and pack paper to guarantee unbroken during the transport.

Wooden case package: For larger scale goods as machine equipment etc, we have special skilled carpenter, who would make the proper wooden case with exact thickness,density,length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent crack and shock. We will inform you the delivery note. You just need to wait for phone call, then pick up the goods at the nearest logistic station .(Please let me know in advance if you want get the goods at home.)

Vacuz Service & Strength

Service tenet

Provide you the best service with “fast + satisfactory + safe”.

Warranty period

12 months long after the user received the product.

Warranty items

Only for abnormal breakdown caused by the machine design or manufacture defect,

free repair and accessory will be provided.

Technology service ability

All service engineers with many years experience are gotten special technology training, who can deal with various breakdown problem.

Guide the user to use accurately and how to maintain the product.

Provide free consultation about production process technology of electronic products.

Service after sell

In order to guarantee the machine used normally, we’d have training on how to operate, use and maintain our product by English manual, video, guiding on line.

Use instruction

Apply for the right complete size of product, otherwise, the wrong dimensions will affect the use effect.

Do ensure using the product accord to the use instruction completely.Do not exceed the scope of application of the products.

Maintain the product after use,Damp proof, rust proof, leak proof, explosion-proof, regular maintenance and inspection should be taken care. All done help to extend the use period.

User document management

Establish perfect user document management in EPR system, Every product running details would be followed to manage. The users would be taken good care.

About product

1. Product photo: All product photos are taken by real product, There is the color aberration between the product and photo, which is caused by shoot light, product size, manual technology and computer display etc. It’s not quality problem. Parts of products

are changed in appearance due to technology revolutionary and process improvement. SanShine would ensure the parameter of product is unchanged, The product couldn’t affect to use.

2.Product size: All parameters are all measured by manual just for reference. There is a small deviation due to the difference of measure tools, lot products and produce process. Real size should be accordance with the final delivery product.

3.Quality inspection: All products should be inspected strictly before shipment. Ensure the good function and appearance.

Vacuz Machine Video