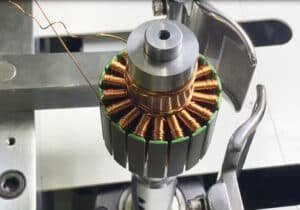

The question of how to properly set the number of turns of the automatic winding machine, many friends may only know some of them superficially, many people do not know or understand these deep things. So how to set the number of turns of the automatic winding machine?

The number of turns of the coil is reacted by the number of turns of the spindle of the winding machine. The number of turns is converted into a pulse signal by a reed sensor and shaped into a square wave by a shaping circuit, which is then differentiated to trigger the counter. When the input given signal consisting of a single-pole two-position switch agrees with the counter’s counting signal, that is, when the pre-set number of turns to be wound, and the number of turns already wound, the gate of the circuit will open, thus sending the signal to the controller, and the winding motor immediately stops rotating to ensure the accuracy of the turn control.

1. Double brake method.

This method involves braking briefly when the winding shaft is wound at high speed in order to stop the slow speed turns. After the winding shaft is stopped, the brake is applied to the unfinished turns of the low-speed winding. In this way, the number of idle turns can be reduced and the winding efficiency can be improved.

2. Forward measurement method.

Primeiro, defina a parada de câmera lenta como zero, defina o número total de voltas como o número de voltas que deseja enrolar, ajuste a tensão do fio etc. corretamente e pressione start para começar a enrolar. Após o enrolamento, você pode saber quantas voltas foram enroladas pelo visor e, em seguida, ir ao editor para subtrair as voltas extras, de modo a obter o número exato de voltas enroladas.

3. High and low speed modes.

Use high speed, low speed and slow stop stop turns to match each other to achieve accurate positioning. The idle turn setting must be sufficient to allow the winding spool to slide to low speed without exceeding the total number of turns setting.

How to set the number of turns of the automatic winding machine, in fact, there is still a certain technology, commissioning personnel or operators need to master these basic elements to ensure that the winding machine can be normal and stable production!

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]