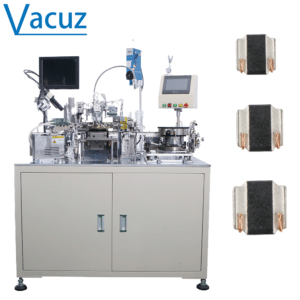

Automatic winding machine is a new type of machine developed in recent years, in order to comply with the requirements of high efficiency and high output, fully automatic machines are generally used in the design of multi-head linkage, most of the domestic consumer manufacturers refer to the design of Taiwan and other places of the imported models, the use of programmable controllers as the control center of the equipment, with the manipulator, pneumatic control elements and implementation of the accessory to complete the automatic line, automatic winding, automatic cut line, automatic loading and unloading of the skeleton and other functions. Automatic loading and unloading of the skeleton and other functions, the consumption efficiency of this model is very high, greatly reducing the dependence on labor, an operator can simultaneously look after several such equipment, the quality of consumption is relatively stable, very suitable for high yield requirements of the processing place. This model due to the integration of CNC, pneumatic, optical control of many new technologies, its advanced and high-yield absorption of customers.

Automatic winding machine manufacturers of automatic winding machine in the winding process, you will hear a very small “uh-en” motion, which is the motion of the motor rolling; shaft sliding will be heard when the guide rail sliding “rowing” motion; occasionally there will be a gas pump to release the gas of the motion, the overall For is relatively pleasant to the ear, will not attack very sharp movement, experienced people can identify through the movement of the winding machine is not anomalous.

Winding machine manufacturers in the design of automatic winding machine in order to comply with the high efficiency, high output requirements, so in the automatic machine type are generally used in the multi-head linkage design, so that the fundamental high efficiency and high output requirements, and most of the domestic consumer manufacturers are referring to Taiwan and other places in the design of imported models, the use of programmable controllers as the control center of the equipment, coupled with the manipulator, Pneumatic control elements and the implementation of accessories to complete the automatic line, automatic foot wrapping, automatic line cutting, automatic loading and unloading of the skeleton and other functions, this design of the model is not only very high consumption efficiency, but also greatly reduces the dependence on labor, an operator to look after several such equipment, unlike the previous to a worker to a machine operation, and so the quality of consumption will be relatively stable, so it is very suitable for those who have high production requirements and high output requirements, so it is very suitable for those who have high production requirements and high output requirements. It is very suitable for those who request a high yield of processing sites, due to high efficiency, coupled with the quality of the packaging, can greatly increase the level of production.

This model due to the integration of CNC, pneumatic, optical control and many other new technologies, so it will be more expensive, the price of light on the small price of tens of thousands of dollars high if up to more than 100,000 yuan, so the price makes many users look forward to, in addition to the functional requirements of the resolution of the parts of the equipment using a large number of non-standardized and customized parts, so that once the presentation of faults, then the relative maintenance process will be more complex, the cycle will also be more complicated. Complex, the cycle will be relatively long, let it continue to work will wait for a period of time, may be very obvious impact on the factory process. But in order to make progress in the efficiency of my factory, its advanced and high yield or absorb the customer.

After-sales is important, not only about the customer is important, about the manufacturer is equally so. Good products are not afraid of maintenance, warranty, insurance, etc., ordinary winding machine manufacturers of my consumption of automatic winding machine quality conditions are comparable to understand, will be based on this situation to develop after-sales program, the quality of bad winding machine manufacturers do not dare to develop a longer period of warranty on the equipment, the ordinary can only provide a short period of time of the warranty service, such as three months, half a year, etc.. The good quality of the consumer manufacturers on their own production quality is relatively confident, the general development of the warranty time is also relatively long. Good after-sales can win the trust of customers, but also for customers to avoid a lot of worry and trouble, why not.

Winding machine manufacturers range is also a reference specification of the quality of automatic winding machine, this is why? Mainly because of the small manufacturers of ordinary funds are thin, on technology, consumption and after-sales investment are relatively small, which forms the structure of the design and consumption quality can not be guaranteed, after-sales is obviously not as large as the range of consumer manufacturers. Scope of the larger automatic coil winding machine manufacturers about each link are invested in a large number of manpower, material and financial support, which from the basic had seconds of small manufacturers. Relatively speaking, or a relatively large range of consumer manufacturers automatic winding machine quality is better.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]