Many manufacturers of brushless motors, the need to buy winding machine equipment, used to complete the stator winding work, but because of the winding machine is not a very good understanding of the preparatory work has not been done, so often take a lot of detours, both a waste of money, but also a waste of time, the loss is not worth it, so what parameters need to be understood to buy brushless stator winding machine? Do what preparatory work? Take a look!

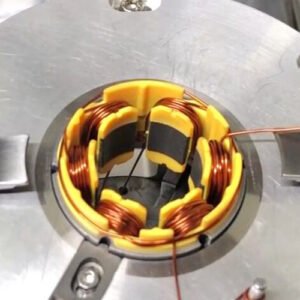

Estator de ferramenta elétrica

1. Stator outer diameter and inner diameter, these two parameters directly determine whether the equipment can be wound, winding machines have a specified range of outer diameter, more than outside the range, the machine is not suitable, need to be customized or choose other winding equipment.

2. Enameled wire diameter size, the winding machine has a specified range of permissible wire diameter, too thick or too fine, may lead to injury or broken wire phenomenon is more likely to occur, need to choose the appropriate winding machine equipment according to the requirements.

3. Stator slot distance, slot distance parameter is very critical, must match the corresponding wire diameter, to ensure that the line is easy to cross, no scratching, injury to the line.

4. single line or multi-line and winding, the two are not the same, for the machine requirements and speed are not the same, you need to determine whether the single line or multi-line and winding.

In the purchase of winding machine before, need to do a good job of preparation, in addition to the stator parameters, but also to learn more about the winding machine manufacturers and qualifications, with what winding is more reasonable, there is the stator core requirements and quality.

Estator de aspirador de pó

Selection of brushless stator winding machine need to know what parameters? Vacuz above has done a simple explanation, I hope that this little knowledge can help you!

E-mail: sales@vacuz.com