Regarding the selection of brushless motor winding machine motor and control system, six key dimensions have been covered, including motor type, control method, winding process adaptability, core component selection, functional scalability and cost optimization. Vacuz will analyze it, further refine and incorporate some creative elements of interpretation, hoping to help everyone!

1. In-depth consideration of motor selection

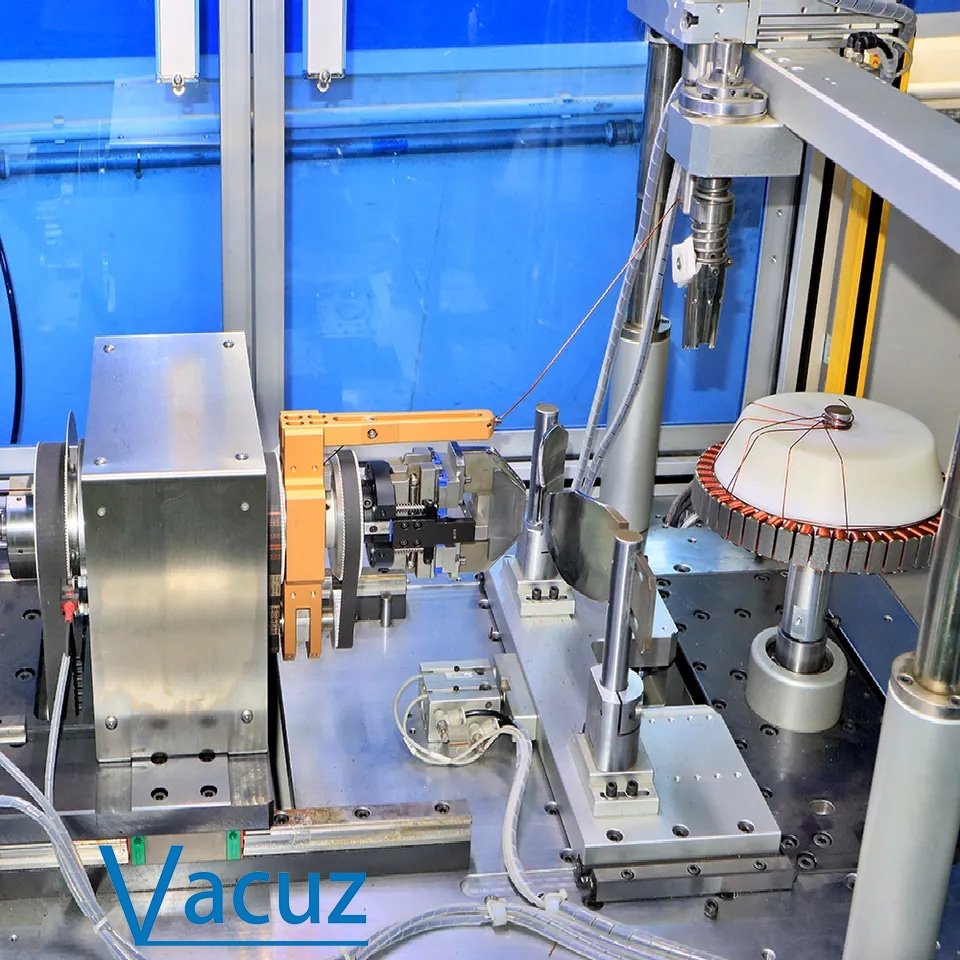

1. Servo motor : As you said, servo motor has become the main choice for precision winding with its high accuracy and high speed. In the scenario of pursuing winding accuracy, more advanced servo drive technology, such as linear servo motor, can be considered to further improve winding efficiency and accuracy.

2. Stepper motor : Considering the cost issue, stepper motor is still a good choice. However, the disadvantage of easy step loss during high-speed operation can be compensated by optimizing the drive algorithm and adding feedback mechanisms, such as encoders, to improve its application range.

2. Intelligent upgrade of control system

1.PLC control: The stability and reliability of PLC system are unquestionable, but with the development of Internet of Things technology, it is possible to consider combining PLC with cloud platform to realize remote monitoring and data analysis, and further improve production efficiency and the convenience of equipment maintenance.

2. Dedicated controller: Dedicated controller has advantages in ease of operation and professionalism, but it can also be further improved by integrating more intelligent functions, such as AI algorithm-assisted winding parameter optimization.

3. Personalized customization of winding machine configuration

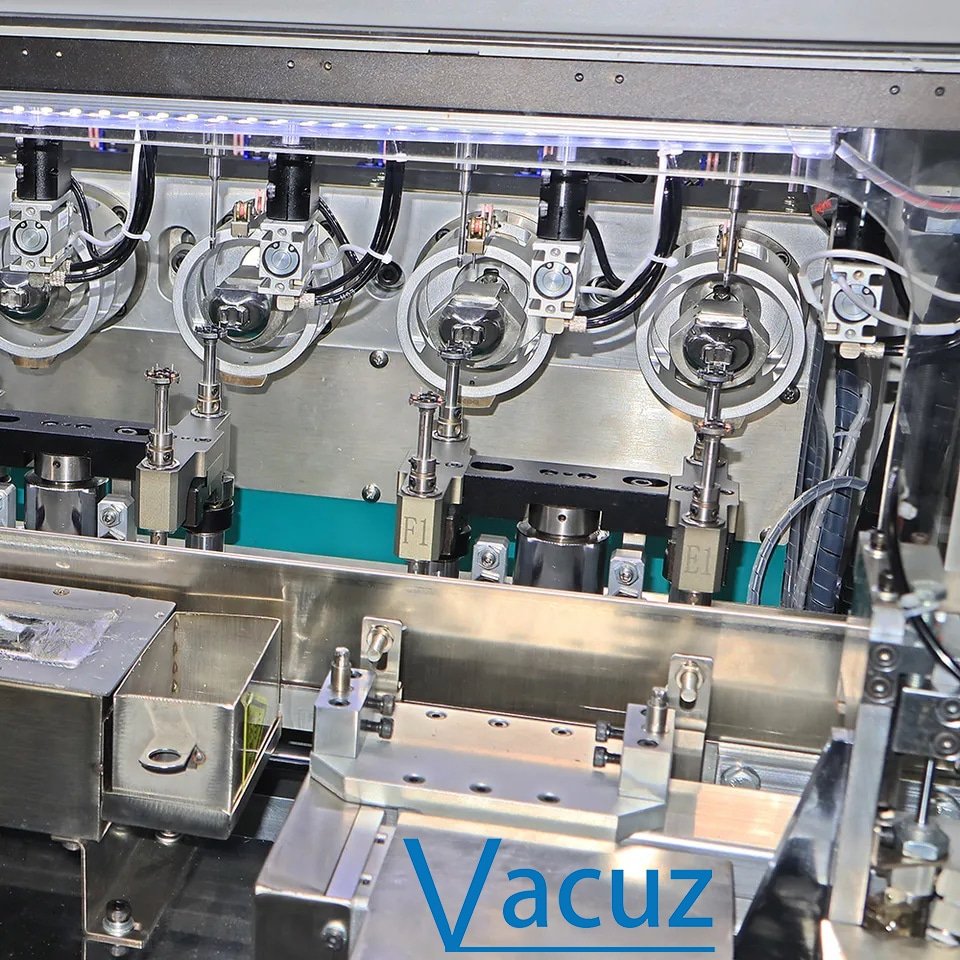

1. Winding head and tensioner: In addition to the basic wear resistance and precision requirements, it is also possible to consider customizing dedicated winding heads and tensioners according to the design of specific brushless motors to achieve a more efficient winding process.

2. Wire arrangement mechanism: For complex multi-layer winding or precision winding requirements, machine vision technology can be introduced to accurately control the wire arrangement position through real-time image recognition to ensure winding quality.

Fourth, innovative strategies for optimizing cost performance

1. Selection of core components: When comparing products of different brands and models, in addition to considering performance, price and after-sales service, you can also pay attention to whether they support modular design, so that they can be upgraded and replaced more flexibly in the future.

2. Functional scalability: In addition to supporting multiple winding methods and replaceable winding heads, you can also consider introducing modular programming technology, allowing users to customize winding logic and process parameters as needed, and improve the flexibility and adaptability of the equipment.

Five, strengthening after-sales service and technical support

1. Establish a rapid response mechanism: Negotiate with suppliers to establish a rapid response mechanism to ensure that repair and replacement services can be quickly obtained when equipment fails.

2. Training and technology sharing: Regularly participate in training courses and technology sharing activities provided by suppliers to enhance the team’s understanding and operation capabilities of the equipment, and also lay a solid foundation for future equipment upgrades and modifications.

How to choose the motor and control of the brushless motor winding machine? Vacuz has made a brief explanation on how to configure cost-effective winding machine equipment. We hope that these suggestions can provide you with new ideas when choosing brushless motor winding machine motors and control systems.

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]