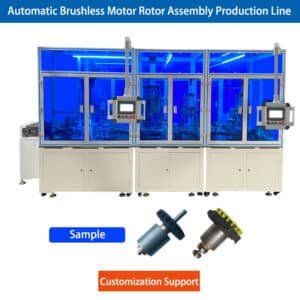

With the continuous development of science and technology, the production of motor gradually towards intelligent, before are manual, semi-automatic or single machine assembly, low efficiency, now with the motor automation production line, parts assembly in one go, the efficiency is greatly improved, simply a good helper of motor production.

For the miniature motor automation production line equipment, how to design the transformation, in order to make the production efficiency to meet the demand?

Micro motor automation production line must be in line with the mainstream production, in the beginning of the design to collect useful information, the procedure, production process and production equipment to understand, more consulting engineering and operation master, from which to obtain some value of information.

2. Understand customer needs, from the customer’s product structure, components, etc., to see how the effect of customer needs, the purpose must be clear, after fully understanding the product, start to determine the program.

3. Determine the program, for the micro motor product assembly components and requirements, to develop the corresponding solution assembly program, the micro motor automation production line trial run requirements data records, many times to verify, audit, to determine the requirements of

4. debugging test, the micro motor automatic production line continuous debugging, so that the entire production line running smoothly, if where there are problems, to timely modify the adjustment, if not solved, then the program should be reformulated.

In the design, it needs to be adjusted according to the actual situation of the project, and after determining the conditions of compliance, the assembly is processed in strict accordance with the process flow, especially the combination of moving parts should be smooth.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]