The design of a brushless motor stator rotor production line for a traversing machine is indeed a complex and delicate process that involves several key design points and details that need to be mastered. So how are the specifics? Here Vacuz gives you an introduction! I hope it can help you!

Production line design points:

First, process planning:

1. Stator production line: covers key steps such as stator skeleton preparation, coil winding, insulation treatment and stator assembly.

2. Rotor production line: including rotor core preparation, magnet installation, shaft press fitting, balance correction, bearing installation and other processes.

3. Integration test: Ensure that the overall performance meets the design requirements after the stator and rotor are assembled.

II. Equipment selection:

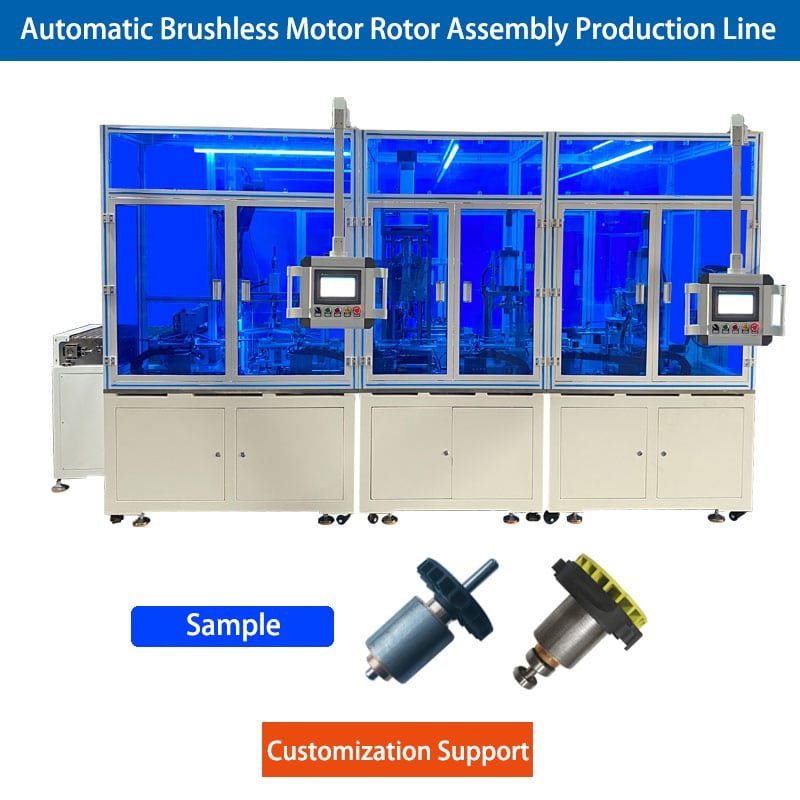

1. Prioritize automated equipment with high accuracy and efficiency, such as automatic winding machines, automatic press-fitting machines, etc.

2. Ensure good compatibility between equipments to realize seamless and continuous production.

Third, layout optimization:

1. Reasonably plan the layout of the production line to reduce the material handling distance and time.

2. Ensure smooth flow of the production line to avoid cross-interference and congestion.

IV.Quality control:

1. Set up quality inspection points in key processes and adopt advanced inspection technology.

2. Establish a quality traceability system to ensure that product quality can be traced.

Details to be mastered:

I. Stator winding technology:

1. Master coil winding methods and techniques to ensure neat coil arrangement and accurate number of turns.

2. Select appropriate winding equipment according to stator parameters.

II.Rotor magnet installation:

1. Ensure that the magnet installation position, quantity and polarity are accurate.

2. Use suitable press-fitting equipment and process to ensure that the magnet and rotor core closely fit.

Third, balance correction:

1. Conduct dynamic balance test on the rotor to ensure smooth rotation without vibration.

2. Adjust the position and weight of the balancing block according to the test results.

Fourth, equipment accuracy and stability:

1. Ensure high accuracy and stability of all equipment.

2. Regular maintenance to keep the equipment in good working condition.

V. Data tracing and monitoring:

1. Establish a perfect data tracing system to record production data and test results.

2. Real-time monitoring of production line status and product quality.

VI. Safety: Give full consideration to equipment protection, electrical safety and fire safety. Formulate safety operation procedures and emergency plans.

How to design the production line of stator rotor of brushless motor for traversing machine? Vacuz above has made a simple explanation, I hope that this little knowledge can help you!

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]