The requirements for brushless motor stator winding and the selection of winding machine equipment are issues that motor manufacturers need to consider, and winding machine manufacturers are also needed to cooperate. So how to evaluate the requirements for brushless motor stator winding? What are the selection criteria for winding machine equipment? Vacuz will introduce it to you!

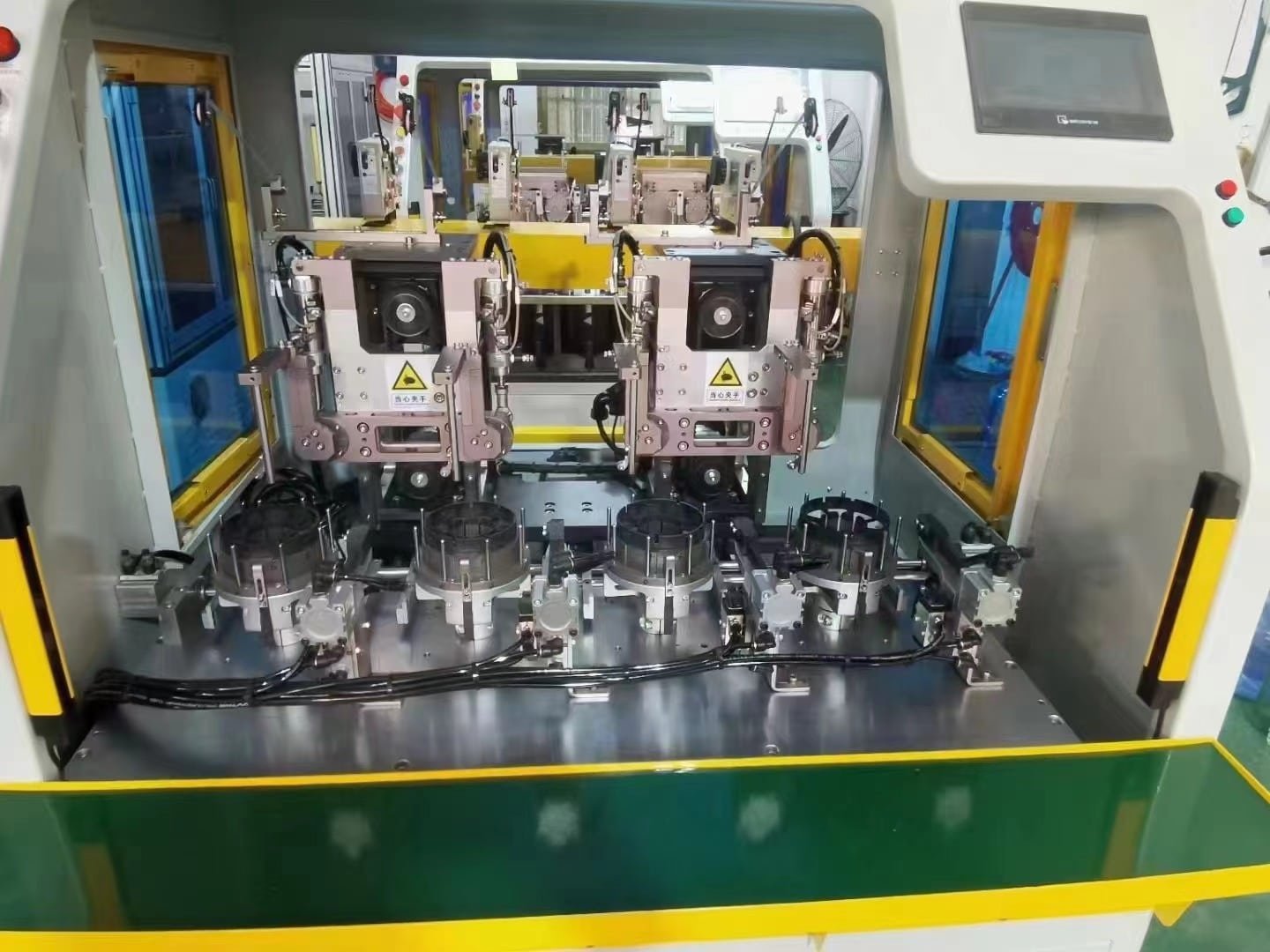

Vacuz FPV UAV Drone Motor Automatic BLDC Brushless Stator Coil Rotor Dynamic Balancing Machine Set Up

1. In-depth analysis of brushless motor stator winding requirements

1. Accurate grasp of stator structural parameters

a. Outer diameter and inner diameter : These two parameters not only determine the applicability of the winding machine, but also indicate the complexity of winding to a certain extent. For example, for large stators with outer diameters beyond the conventional range, special winding strategies and equipment configurations may be required to ensure the uniformity and tightness of the winding.

b. Stack thickness : The size of the stack thickness directly affects the design of the winding machine and the selection of the winding process. Stators with high stack thickness require the winding machine to have stronger span and tension control capabilities to ensure the stability and quality of the wire during the winding process.

c. Number of slots and slot distance: The number of slots is directly related to the complexity and time of winding. The slot distance needs to be accurately matched with the wire diameter to avoid quality problems such as scraping or breaking during the winding process.

2. Fine control of winding process parameters

a. Wire diameter and multi-wire winding: The thickness of the wire diameter not only affects the speed and quality of winding, but also puts higher requirements on the tension control system of the winding machine. When winding multiple wires, it is necessary to ensure that the tension between each wire is uniform and the winding is synchronized to avoid problems such as looseness or knotting.

b. Number of coil turns and winding speed: The number of coil turns directly determines the time and efficiency of winding. Under the premise of ensuring quality, increasing the winding speed can significantly improve production efficiency. However, it should be noted that an increase in the number of turns may increase the complexity and difficulty of winding, so it is necessary to choose a suitable winding machine and process parameters to balance.

c. Winding method: It is crucial to choose a suitable winding method according to the slot direction of the stator. Internal winding machines and external winding machines each have their own characteristics and scope of application, and need to be selected according to actual conditions.

3. Strict compliance with quality and safety requirements

a. Winding accuracy: The accuracy of the number of coil turns and wiring accuracy is directly related to the performance and reliability of the motor. Therefore, various parameters need to be strictly controlled during the winding process to ensure the accuracy and quality of the winding.

b. Insulation layer protection: During the winding process, special attention should be paid to protecting the insulation layer of the enameled wire to prevent it from being damaged or destroyed. Otherwise, it may cause the motor performance to deteriorate or malfunction.

c. Safe operation: The winding machine equipment needs to be equipped with complete safety protection devices and warning signs, and the operator needs to strictly abide by the safety regulations and operating procedures to ensure personal safety and stable operation of the equipment.

II. Comprehensive consideration of the selection criteria for winding machine equipment

1. Comprehensive evaluation of equipment performance and adaptability

a. Number of workstations and efficiency: Selecting the appropriate number of workstations according to the size and output requirements of the stator can significantly improve the winding efficiency. However, it should be noted that the increase in the number of workstations may increase the complexity and cost of the equipment, so comprehensive consideration is required.

b. Tension control accuracy: Tension control is a crucial part of the winding process. For winding tasks with thin wire diameters or parallel winding, it is necessary to select winding machine equipment with high-precision tension control capabilities to ensure the stability and quality of the wire.

c. Wire arrangement system: Complex winding tasks require an accurate wire arrangement system to ensure the uniform arrangement and tightness of the wire. When selecting a winding machine, special attention should be paid to the performance and accuracy of its wire arrangement system.

2. Accurate selection of equipment type and process matching

a. Inner winding machine and outer winding machine: Selecting the appropriate winding machine type according to the slot direction of the stator can significantly improve the winding efficiency and quality. The inner winding machine is suitable for stators with slots facing inward, while the outer winding machine is suitable for stators with slots facing outward.

b. High-speed winding machine: For products with many turns and high efficiency requirements (such as fan stators), it is necessary to select winding machine equipment with high-speed winding capabilities to meet production needs.

c. Non-standard customization capabilities: For stators with special sizes or complex winding requirements, it is necessary to select manufacturers with non-standard customization capabilities to customize equipment and optimize processes to ensure production efficiency and product quality.

3. Strict control of equipment quality and reliability

a. Quality of key components: The quality of key components such as servo motors, lead screws, and guide rails directly affects the stability and service life of the equipment. When selecting winding machine equipment, special attention should be paid to the specifications and performance parameters of these components to ensure the quality and reliability of the equipment.

b. No-load operation test: After the equipment is installed and debugged, a no-load operation test is required to observe whether its operation is smooth and whether the speed is stable. This helps to promptly discover and solve problems to ensure the normal operation and production efficiency of the equipment.

c. Noise and energy consumption: Low-noise and low-energy consumption equipment can not only improve the comfort of the production environment but also reduce operating costs. When choosing winding machine equipment, special attention should be paid to its noise and energy consumption indicators to meet environmental protection and energy saving requirements.

4. Perfect guarantee of after-sales service and technical support

Warranty period and maintenance response: Choosing a manufacturer that provides a longer warranty period and fast maintenance response can ensure that the equipment can be repaired and maintained in a timely and effective manner when a failure occurs, so as to extend the service life of the equipment and reduce maintenance costs.

Operation training and technical support: The manufacturer needs to provide equipment operation training and technical support to help users quickly master the use of the equipment and maintenance skills to improve production efficiency and product quality. At the same time, the manufacturer also needs to provide timely and effective technical support to solve the problems and difficulties encountered by users during use.

3. Scientific implementation of comprehensive evaluation and selection process

1. Collect stator parameters: Before selecting winding machine equipment, it is necessary to collect various parameters of the stator, including outer diameter, inner diameter, stack thickness, number of slots, slot distance, wire diameter, number of turns, etc., in order to accurately evaluate the winding task and select appropriate equipment and process parameters.

2. Determine the winding process: Select the appropriate winding method (inner winding or outer winding) according to the structure and parameters of the stator and clarify the requirements of winding speed, tension, etc. to ensure the quality and efficiency of winding. At the same time, it is also necessary to consider factors such as the type and specification of the wire and the design and manufacture of the mold to meet production needs.

3. Select the type of equipment: Select the appropriate type of winding machine (inner winding machine, outer winding machine or high-speed winding machine) according to the needs of the winding process and determine the number of stations and configuration to meet the requirements of production efficiency and product quality. At the same time, it is also necessary to consider factors such as the compatibility, scalability and upgradeability of the equipment to adapt to changes in future production needs.

4. Verify the adaptability of the equipment: Verify the adaptability of the equipment with the stator and mold through winding tests, and evaluate the winding quality and efficiency.

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

Comprehensively evaluate the quality of equipment and after-sales: Select equipment manufacturers with reliable quality and perfect after-sales service to ensure that the winding quality meets the requirements.

E-mail: sales@vacuz.com