Winding the stator of a brushless motor requires a winding machine. Pin winding machines are a common internal winding machine suitable for brushless stators with inward-facing slots and are widely used. So, what are the conditions for stable operation of a fully automatic pin winding machine? How can winding requirements be met? Vacuz will explain.

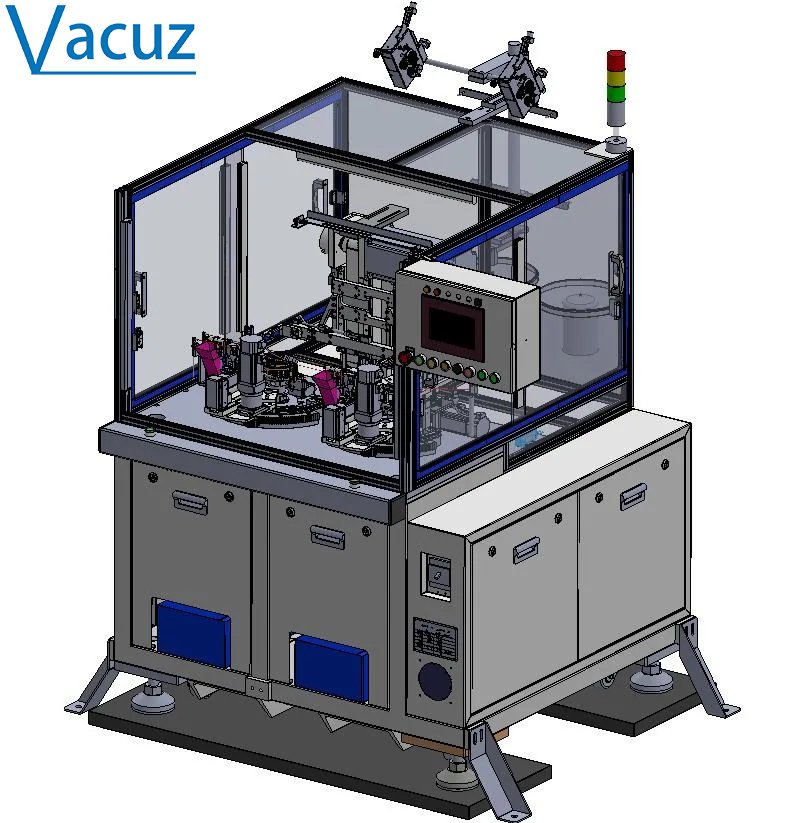

46 estações Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

I. Stable Operating Conditions

1. Reliable Grounding and Electrical Safety

Emphasize regular testing of ground resistance to ensure compliance with national standards and prevent electrical safety hazards.

Mention the use of safety devices such as leakage protectors to further enhance electrical safety.

2. Stable Working Environment

Detailed instructions on securing the workbench to the floor, such as using expansion screws, are provided to ensure the stability of the equipment.

Emphasize the importance of environmental isolation, such as installing isolation tape or protective covers to reduce external interference.

3. Appropriate Load Usage

Provide specific guidance on equipment load usage, such as developing a load usage table based on wire diameter and winding speed.

Emphasize the hazards of overloading, such as motor overheating and mechanical wear.

4. High-Quality Accessories and Systems

List the brands and models of core components to facilitate user selection of high-quality accessories.

Emphasize regular updates and upgrades to ensure optimal equipment performance.

5. Operator Professional Competence

Provide operator training plans and assessment standards to ensure operators possess professional skills.

Emphasize operator safety awareness, such as the wearing of personal protective equipment (PPE) such as safety glasses and gloves.

6. Factory Testing and Acceptance

Detail the specific items and standards for factory testing, such as winding accuracy, speed, and safety features.

Provide an acceptance report template to facilitate user equipment acceptance.

II. Methods for Meeting Winding Requirements

1. Accurately Setting Winding Parameters

Provide recommended settings for slow winding and slow stop parameters for start and stop, such as the number of slow winding turns and slow stop time.

Emphasize the importance of setting the cable routing and rotation direction, and provide detailed setting methods.

2. Multi-wire Parallel Winding Technology Optimization

Provides specific notch design dimensions and tolerances to facilitate notch processing.

Emphasis is placed on the importance of stack thickness control and provides methods for selecting and adjusting servo tensioners.

3. Precision Tension Management

Provides recommendations for servo tensioner selection, such as selecting the appropriate tensioner based on wire diameter and material.

Emphasis is placed on the importance of dynamic adjustment and provides reference ranges and frequencies for tension adjustment.

4. Enhanced Equipment Stability

Provides specific improvement measures for mechanical structure stability and precision transmission, such as strengthening the rigidity of the frame and chassis and using high-precision lead screws and guide rails.

Emphasis is placed on the importance of equipment commissioning and maintenance and provides professional commissioning and maintenance recommendations.

5. Process Optimization and Automation Upgrade

Provides specific methods and case studies for efficient winding path design.

Emphasis is placed on the principles and implementation of collaborative control between PLC motion controllers and servo systems.

Provides recommendations for upgrading automation functions, such as the implementation and application of touchscreen programming, automatic angle wrapping, and quick reset mechanisms.

Vacuz P&D Equipamento para máquina de enrolamento de agulha de bobina de estator de motor sem escova BLDC interno automático de duas estações

What are the stable operating conditions for a fully automatic stator needle winding machine? How can winding requirements be met? Vacuz has briefly explained this above, and we hope this knowledge can be helpful to you!

E-mail: sales@vacuz.com