Nowadays, automatic winding machines are equipped with speed regulation function to satisfy different winding requirements. Following the opening of large-plan integrated circuits and computer control skills, as well as the use of modern control theories, it makes the communication frequency conversion speed control become the primary speed control method of the winding machine, and the modern communication speed control skills have the outstanding skills such as wide speed control planning, high speed stabilization planning and accuracy of stabilization, fast dynamic response and reversible operation, which make the speed control function greatly improved. Modern communication speed control technology has wide speed control planning and high speed stability planning and accuracy, fast dynamic response and reversible operation and other excellent skills, making the speed control function has been greatly improved.

Automatic winding machine manufacturers in the proposed energy-saving low-carbon environment of frequency conversion speed control has an absolute advantage, and its speed function and reliability continue to improve, prices continue to fall, especially frequency conversion speed control power saving effect is obvious, and easy to end the process of automation, by the winding machine industry and other industrial occupations recognized.

Communicating frequency conversion skills with speed regulation when the smoothness is good, high efficiency. At low speeds, the characteristics of the static shutdown rate is high, the relative stability of the characteristics of good, winding machine in the winding operation, such as the presentation of the speed control is not smooth will be presented in the broken line and line system out of step, the use of frequency converter is very good to avoid the presentation of such problems, the winding machine in order to satisfy the different processes of the winding process, often need to be large planning and high-precision speed, which is very suitable for the characteristics of the speed of frequency converter; the modern winding machine its control system Modern winding machine control system are generally selected digital integrated circuits, and DC governor and electromagnetic governor is more difficult to cooperate, frequency converter can be directly used integrated circuit control, easy to end the process of automation.

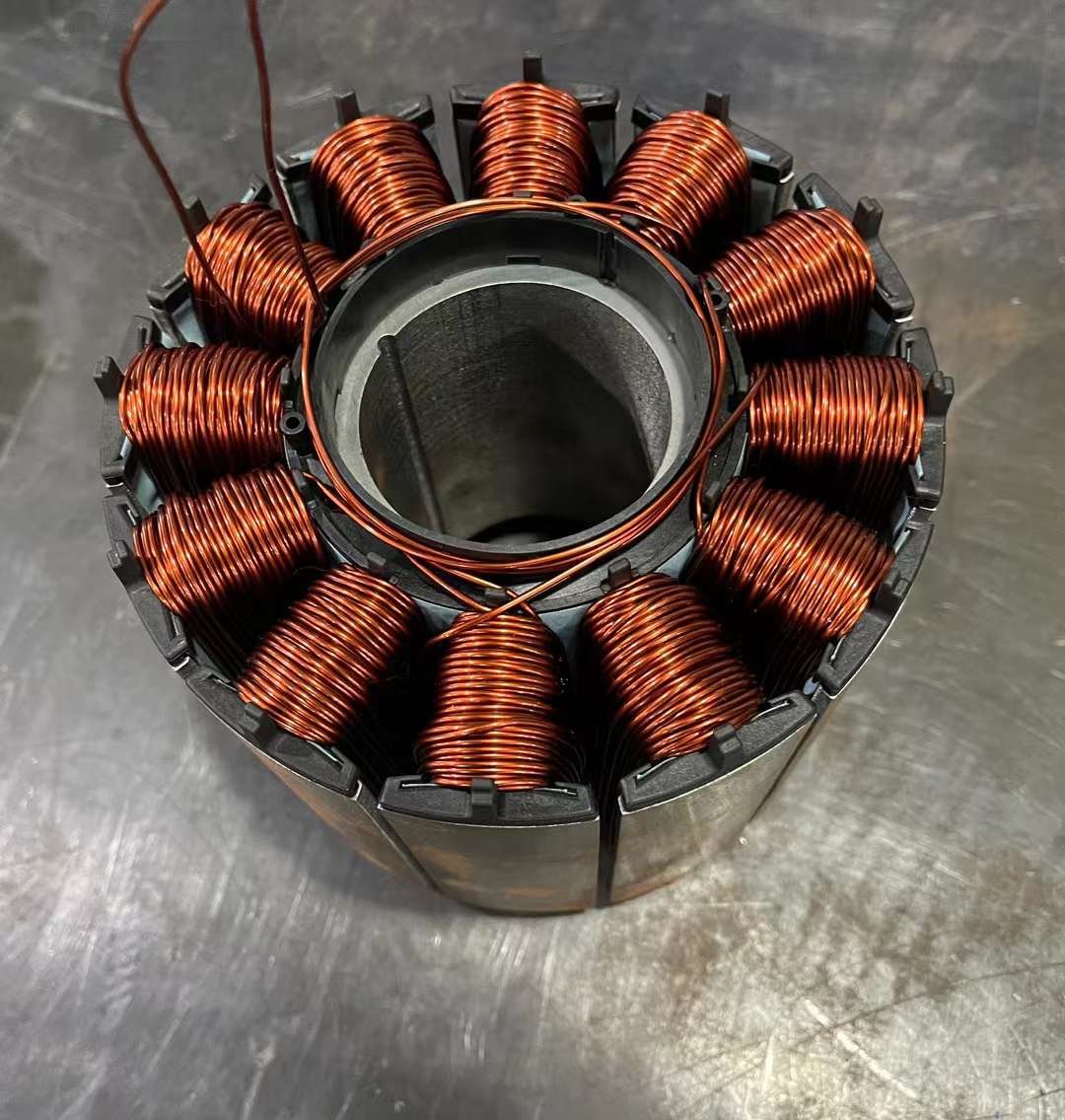

Winding machine manufacturers in the use of servo systems used to be commonly used, such as improved DC motors, small inertia DC motors, permanent magnet DC motors, brushless DC motors and so on. Since entering the new century, the spindle drive skills based on communicating asynchronous motors and permanent magnet synchronous motors have been opened up agilely, which is a direction of the CNC winding machine implementation organization to open up. Due to the CNC winding machine on the servo system puts forward strict technical requirements, the servo system also comes with its own special implementation of the servo motor puts forward strict requirements.

Servo system used in the spindle system of the winding equipment can significantly improve the stability of the equipment winding, instead of the traditional DC motor and electromagnetic speed motor, the use of servo advantages are clear, according to the high speed, can end the accurate positioning of the spindle and to meet the self-locking requirements, in the compact structure of the winding equipment saves the use of space, and more conducive to the heat dissipation of the equipment.

Coil winding process is not only the winding process, but also need the winding equipment to end the accurate and orderly line action, general winding equipment are generally used stepper motor driven displacement screw end line, due to the stepper motor selection of the open-loop control, affecting the accuracy of its line, the use of servo system can be advanced line accuracy to meet the high-speed line action, reduce the noise of the operation of the coil winding machine.

WhatsApp/Wechat: +86 13075286997

E-mail: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]