Winding machines have gone through most of the century from hand-cranked to semi-automatic, and then to fully automatic winding machines. At present, with the development of science and technology, electronic and electrical industries are handling coils and other products every day. The winding machine is an indispensable equipment.

Currently, semi-automatic winding machines are widely used in the market, which can only achieve automatic wire arrangement, and all the rest of the operations need to be done manually. Another disadvantage of semi-automatic winding machines is that they need to be equipped with more manpower, and employees need certain training, and the efficiency of work is also affected by the proficiency of operators. In contrast, there is still a big difference between fully automatic winding machines and ordinary winding machines (i.e. manual or semi-automatic).

Automatic winding machine and ordinary winding machine differences

1, product positioning is different: fully automatic positioning in large and medium-sized enterprise users, manual or semi-automatic winding machine is generally suitable for general small enterprises or processing plants to use, more economical.

2, design structure differences: fully automatic winding machine tends to be fully automated to achieve a more complex structure, but easy to operate, greatly saving time and improving efficiency, while ordinary winding machine quality is slightly worse, material collection and simple structure, manual operation is not as efficient as the former.

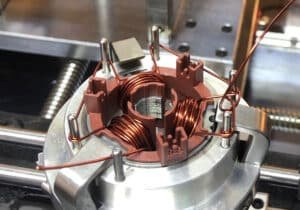

Înfășurarea bobinei

3, manufacturing costs are different: the cost of full automation is higher, while the cost of manual or semi-automatic winding machines is lower, which is also based on the consideration of different user groups.

4, functionally different: the former has a variety of functions, the whole process of digital control, display all-in-one operation; the latter is mostly manual control, can be used.

5, winding accuracy there are obvious differences: the invention of fully automatic cashing and can greatly improve the accuracy of coil winding, small error, winding closure uniform, ordinary winding does not have the advantage of fully automatic, small number of turns of the coil, the requirements of small then can be competent;.

6. slightly different types of products produced: the former can wind more types than the latter because it is more intelligent.

7. Differences in technical support.

Automatic winding machine has professional technical support, when problems arise, it is easy to find the appropriate solution, while the latter is relatively inconvenient to find a solution, because the brand type is more complex, the use of technical means are not uniform.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com