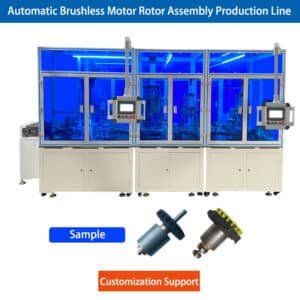

Rotor assembly line is mainly used for the rapid assembly of rotor spare parts production, reasonable design and quality selection of materials, can improve the operating efficiency and stability of the production line, so the rotor assembly line specific how to design more humanized? How to improve the stability of performance, Vacuz give you an introduction!

Linie de producție automată pentru asamblarea rotorului motorului fără perii

Design rotor assembly line to be more humane, improve stability, can be considered from the following aspects:

First, design a more humanized rotor assembly line.

1. Simple operation interface:

Adopt a touch screen or human-machine interface system to provide an intuitive and easy-to-understand graphical interface to reduce the difficulty of operation. Allow operators to complete complex operations by simple clicking or dragging, reducing operating steps and time.

2. Humanized layout: According to the principle of ergonomics, the equipment and operating table are reasonably arranged to ensure that the operator operates in a comfortable working posture. Considering the operating range and vision of the operator, avoiding long time movements such as bowing, bending or reaching.

3. Intelligent prompting and alarm system: real-time display of production status, process parameters and other information, so that the operator can understand the production situation at any time. When the equipment malfunctions or encounters abnormal situations, it can automatically send out alarm signals and provide troubleshooting suggestions.

3. Modularized design: the production line is divided into several independent modules, each module performs a specific function. Standardized interfaces and connections are used between modules to facilitate rapid replacement and maintenance.

Second, improve the stability performance of the rotor assembly line.

1. High-quality equipment and accessories: Use well-known brands and reliable quality equipment and accessories, such as motors, cylinders, sensors and so on. Regularly check and maintain the equipment and accessories to ensure that they operate in good condition.

2. Reasonable structural design: design a reasonable production line structure according to the production requirements and process characteristics. Ensure smooth connection between equipment and reduce unnecessary friction and vibration.

3. Advanced control system: Adopt advanced PLC (programmable logic controller) or motion control system to realize accurate control and positioning. Sensors and feedback system are introduced to monitor various parameters in the production process in real time to ensure stable and reliable production.

4. Real-time monitoring system: establish a real-time monitoring system to monitor and analyze the operation status of the production line in real time. When abnormal situation is found, it can automatically adjust the parameters or send out alarm signals to solve the problem in time.

5. Complete maintenance and upkeep program: Establish a detailed maintenance and upkeep program to clean, lubricate, fasten and other operations of the production line on a regular basis. Regular replacement and repair of key equipment and components to prevent failure.

6. Training and technical support: Provide professional training and technical support for operators to improve their operating skills and troubleshooting ability. Provide remote technical support and online help to ensure the stable operation of the production line.

Linia de producție BLDC Motor Stator Coil

How to design the rotor assembly line more humanized? How to improve the stability of the performance of Vacuz above has done a simple explanation, I hope that these tips and details can help you!

Email: sales@vacuz.com