When we test the high precision automatic winding machine, we generally verify the reliability of the automatic winding machine system through the intermodulation of the control system and mechanical system to meet the function, and verify the control accuracy of the automatic winding machine control system through the measurement data of laser interferometer and CMM. Specific operations are as follows.

1, the operation basis of the automatic winding machine system

The operation basis of the automatic winding machine system, including the entire system power supply test, servo motor pointing function test, limit test, drive parameter settings

1.1 System power supply test

The system power supply test is mainly to test whether the system and control card, industrial control computer, servo motor and driver status are normal after the system is powered on. And start the software, test the motion control card and PCI bus connection communication is normal. Then it is necessary to test whether the status signal of each limit switch is normal.

Before testing the power supply, it is required to disconnect the circuit breaker of each axis load motor, computer and heating unit power supply line according to the power distribution line, and confirm the output power polarity of the switching DC power supply. Also check the polarity of each load, especially the DC power supply! After power on, first check the input and output voltage and polarity of the switching power supply. After normal, close the circuit breaker for each load step by step to confirm that there is no abnormality in power supply, and then proceed to the next step of commissioning.

1.2 Drive setting and point operation

After the power supply is normal, the key parameters of the servo drive need to be set up, including the servo system operation mode and the related PID adjustment parameters. All settings are done through the control panel of the servo drive.

The input pulse string form is selected as command pulse and command symbol, i.e. pulse+direction mode, and the wiring input method of the drive in this mode is open collector mode.

The direction of rotation is positive by default, but the direction of the two clamping mandrel servo motors must be opposite, because this can ensure that the two clamping mandrels maintain the actual operation of the through rotation start-stop.

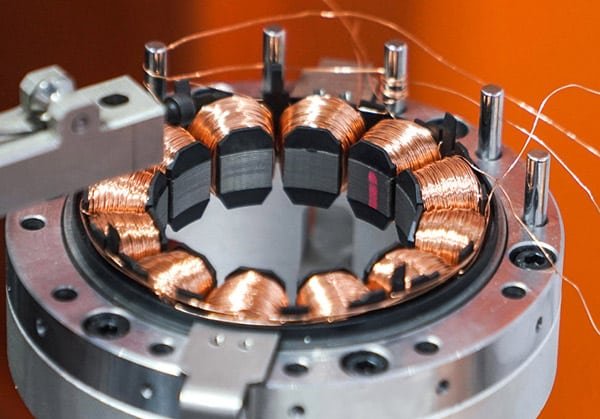

After the parameters are set, the machine will enter into point operation. Through the control panel of the servo driver, we will test whether the motor operation can be manually run normally. The commissioning operation of the high precision winding machine control system is shown in Figure 5.2. The pointing operation is used to verify whether the servo motor is working properly.

The load inertia ratio is selected as default.

For the servo drive adjustment mode of the winding machine, there are automatic, semi-automatic, and manual modes. Generally when the automatic gain adjustment mode is selected, when the gain data is larger, the command traceability and positioning adjustment time is shorter, but if it is too large, the motor generates vibration. The general reference value of ball screw structure is 10-15; but often, in order to get better control effect, most cases need to choose manual mode to adjust according to the mechanical structure and load of the equipment’s drive.

When the mode of the servo drive is selected as manual mode, the load inertia ratio, position gain regulator value, speed response, speed regulator integration time, feed forward filter time constant, and torque filter time constant of the servo drive can be manually adjusted.

The position mediation gain is the parameter that determines the responsiveness of the position control loop. If the setting value is increased, the response to overload disturbances will be faster. However, if the setting value is too large, overtravel tends to occur.

Speed response is the parameter that determines the responsiveness of the speed control loop. If the setting value is lowered, the adjustment result that values servo motor responsiveness is obtained, but if the setting value is too small, the mechanical system is prone to vibration.

The integration time of the speed regulator is a parameter that determines the responsiveness of the speed control loop. If the setting value is reduced, the adjustment result that values servo motor responsiveness is obtained, but if the setting value is too small, the mechanical system is prone to vibration.

Feedforward filter time constant is a parameter for feedforward filter of position command and position command setting traceability.

It is independent of the feedforward gain value and is always valid. If this parameter is reduced, the responsiveness is accelerated, but it is prone to torque shocks.

The torque filter time constant is a parameter for filtering control of the torque command. An increase of the parameter has the effect of suppressing mechanical resonance, but sometimes destabilizes the control.

In short, the main purpose of the adjustment of the gain parameter is aimed at the load inertia ratio, which is defined as the ratio of the load moment of inertia of the mechanical system relative to the motor shaft (motor shaft converted load moment of inertia) to the motor moment of inertia to, and the size of the inertia ratio is mainly determined by the reference moment of inertia calculation formula.

The above-mentioned parameters are only necessary to set the parameters of the drive, more parameter settings need to refer to the user manual of the drive. And to make the servo drive to the motor performance to achieve a desirable effect, the winding machine can be adjusted to many parameters, in addition to the drive can also be set through 485 serial communication of the various parameters. And in the later commissioning operation, the parameters need to be constantly fine-tuned.

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]