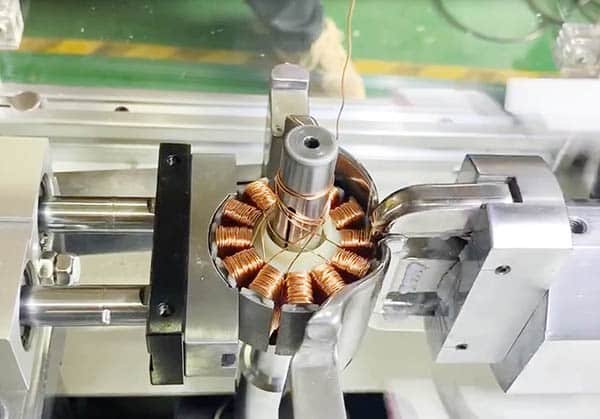

Times are different, the industry’s development speed, economic aspects are different, in the 21st century, follow the footsteps of the times, most of the industry in the development of a relatively full, such as the application of automatic winding machine, in electronic equipment, or electrical appliances, or electric coil equipment processing, are required to use to automatic winding machine, automatic processing, simple operation, speed, the development of the industry also has a certain impact, but On the use of automatic winding machine rules, there will still be people who do not particularly understand, the following a step to teach you!

1. Whether the winding machine is used normally, regular inspection is more than indispensable, but also to ensure that the equipment can work properly and effective measures. AC frequency conversion technology has good smoothness and high efficiency when speed regulation. Low speed, the characteristics of the static off rate is high, the relative stability of the characteristics of good, winding machine in the winding operation, such as speed regulation is not smooth will appear broken wire and line system out of step, the use of inverters to avoid such problems, winding machine in order to meet the winding process of different processes, often need a wide range of high-precision speed regulation, which is very consistent with the speed characteristics of the inverter; modern winding machine control system Modern winding machines generally use digital integrated circuits for their control systems, which are more difficult to work with DC and electromagnetic governors, and inverters can directly use integrated circuits to control and automate the process.

With the development of large-scale integrated circuits and computer control technology, as well as the application of modern control theory, AC frequency control has become the main winding machine speed regulation, modern AC speed control technology has a wide range of speed regulation, high speed range and speed stability accuracy, fast dynamic response and reversible operation and other good technical performance This makes the speed control performance is greatly improved. In the general environment of advocating energy saving and low-carbon, frequency control has advantages, and its speed performance and reliability continue to improve, the price continues to reduce, especially the frequency control effect of power saving, and easy to achieve process automation, by the winding machine industry and other industrial industries recognized.

3. Keep in mind the technical standards and maintenance points of the winding machine, and the correct and reasonable use of equipment, is to keep the basic conditions of the equipment intact, any over-standard use of equipment will accelerate the aging of the equipment and the occurrence of failure

WhatsApp/Wechat: +86 13075286997

Email: sales@vacuz.com [fusion_form form_post_id="431″ margin_top="" margin_right="" margin_bottom="" margin_left="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][/fusion_form]